Preparation method of high nitrogen steel

A high-nitrogen steel and molten steel technology, applied in the field of high-nitrogen steel smelting, can solve problems such as limited thickness of nitriding layer, long nitriding time, unsuitable for large-scale production, etc., and achieves obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

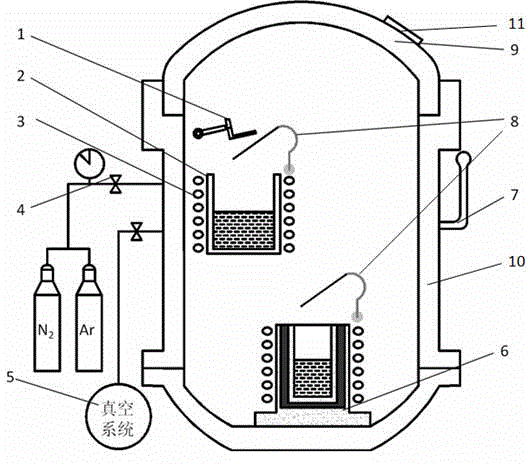

[0023] In this embodiment, Cr9Mn11Ni0.5 austenitic stainless steel (see Table 1 for composition) is used as the processing object, and specifically includes the following steps:

[0024] Table 1 Composition of stainless steel Cr9Mn11Ni0.5 alloy used in experiments (%)

[0025]

[0026] (1) Place the alloy Cr9Mn11Ni0.5 austenitic stainless steel in the melting crucible 2, close the melting furnace, start the vacuum device 5 to evacuate to 100Pa, turn on the melting device 3 to heat the sample until it melts, open the nitrogen cylinder valve 4 to fill 0.6MPa industrial nitrogen (nitrogen purity over 99%); the molten metal is kept in a high-pressure nitrogen atmosphere for 20 minutes and the temperature of the molten metal is kept at 1450°C to ensure that the N 2 fully dissolved;

[0027] (2) Adjust the power to keep the molten metal at 1400°C (the liquidus temperature is 1430°C, and the solidus line temperature is 1330°C). The holding time is 5min, 10min, 15min, and 20min re...

Embodiment 2

[0031] This embodiment takes Cr9Mn11Ni0.5 austenitic stainless steel as the processing object, and specifically includes the following steps:

[0032] (1) Place the alloy Cr9Mn11Ni0.5 austenitic stainless steel in the melting crucible 2, close the melting furnace, start the vacuum device 5 to evacuate to 100Pa, turn on the melting device 3 to heat the sample until it melts, open the nitrogen cylinder valve 4 to fill 0.1MPa industrial nitrogen (nitrogen purity over 99%); the molten metal is kept in a high-pressure nitrogen atmosphere for 15 minutes and the temperature of the molten metal is kept at 1550°C to ensure N 2 fully dissolved;

[0033] (2) Adjust the power to keep the molten metal at 1380°C (the liquidus temperature is 1430°C, the solidus temperature is 1330°C), the holding time is 5min, 10min, 15min, 20min respectively, and the temperature is controlled during the whole process With the help of thermocouple 8, turn off the power of the equipment after the heat preser...

Embodiment 3

[0037] This embodiment takes Cr9Mn11Ni0.5 austenitic stainless steel as the processing object, and specifically includes the following steps:

[0038](1) Place the alloy Cr9Mn11Ni0.5 austenitic stainless steel in the melting crucible 2, close the melting furnace, start the vacuum device 5 to evacuate to 100Pa, turn on the melting device 3 to heat the sample until it melts, and open the nitrogen cylinder valve 4 to fill 2MPa industrial nitrogen (nitrogen purity over 99%); the molten metal is kept warm for 30 minutes under a high-pressure nitrogen atmosphere and the temperature of the molten metal is kept at 1400°C to ensure that the N 2 fully dissolved;

[0039] (2) Adjust the power to keep the molten metal at 1350°C (the liquidus temperature is 1430°C, the solidus temperature is 1330°C), the holding time is 5min, 10min, 15min, 20min respectively, and the temperature is controlled during the whole process With the help of thermocouple 8, turn off the power of the equipment aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com