Symmetrical vapor deposition equipment reaction cavity

A technology of reaction chamber and vapor deposition, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of reaction chamber pollution, unsophisticated design, increased floor space and cost, etc., to achieve The effect of improving uniformity and improving process quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

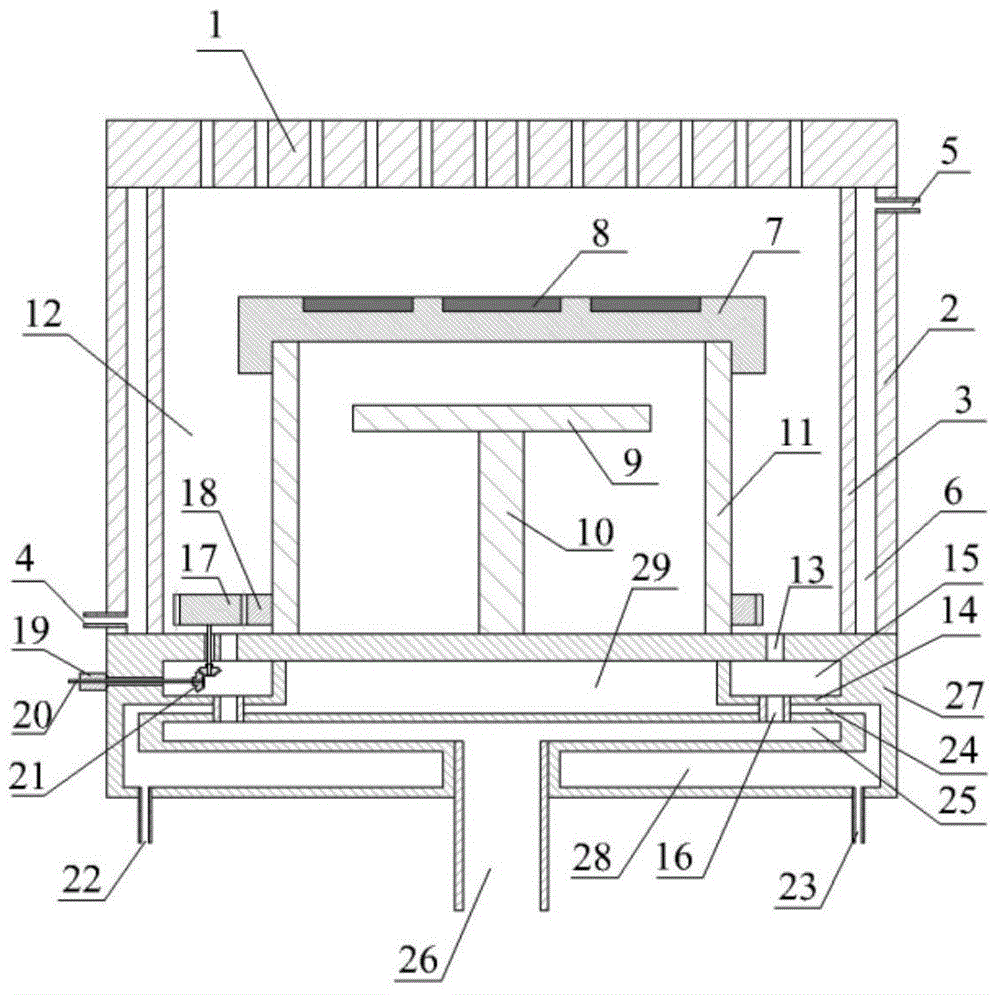

Embodiment 1

[0017] see figure 1 , the reaction chamber is provided with a reaction gas input body 1 and an exhaust gas outlet 26, and the exhaust gas outlet 26 is arranged at the center of the cavity base 27, in the reaction gas input body 1, the reaction gas channel 12, and the annular gas buffer chamber 15 1. The symmetrical position of the center of the air cavity 25, so as to maintain the symmetrical characteristics of the gas from entering to flowing out. A reaction gas channel 12 is provided in the reaction chamber, a chamber wall cooling chamber 6 is provided between the chamber shell 2 and the reaction chamber inner wall 3, and the chamber wall cooling chamber 6 is provided with a chamber wall cooling liquid inlet 4 and a chamber wall cooling liquid outlet 5 There is an annular gas buffer cavity 15 and an air cavity 25 in the middle of the cavity base 27. There is an annular gas buffer cavity 15 connected to the reaction gas flow channel 12 in the cavity base 27. The buffer cavity...

Embodiment 2

[0021] Same as Embodiment 1, the difference is that the cavity wall cooling cavity 6 , the cavity upper base cooling cavity 29 , and the lower base cooling cavity 28 are also provided with cooling liquid channel grooves along which the cooling liquid flows.

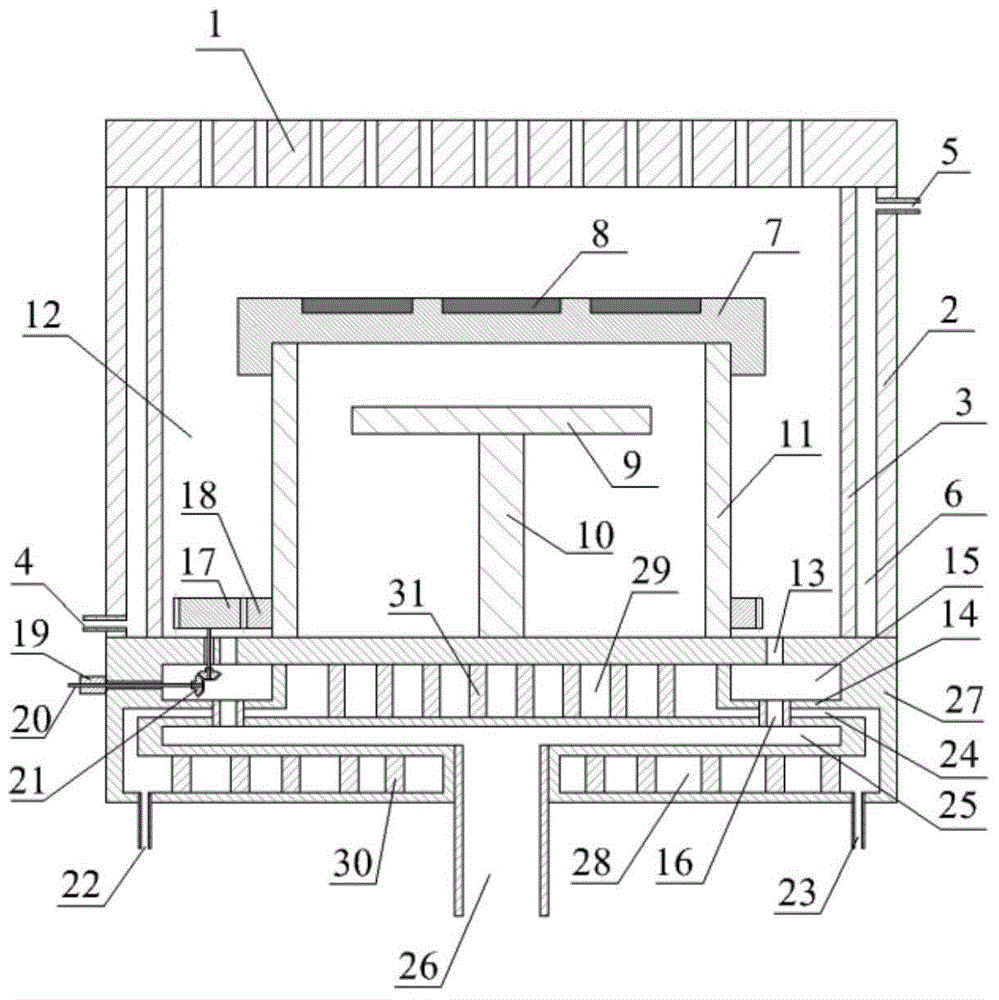

[0022] In the upper cooling chamber 29, a partition 31 is used to set a specific flow channel for the upper coolant, and the lower cooling chamber 28 is also provided with a partition 30 to form a specific flow channel, see figure 2 As shown, the flow of coolant in a specific channel can be controlled through the design of the partition, which can reduce the flow dead zone, enhance heat exchange, and further improve the cooling effect.

Embodiment 3

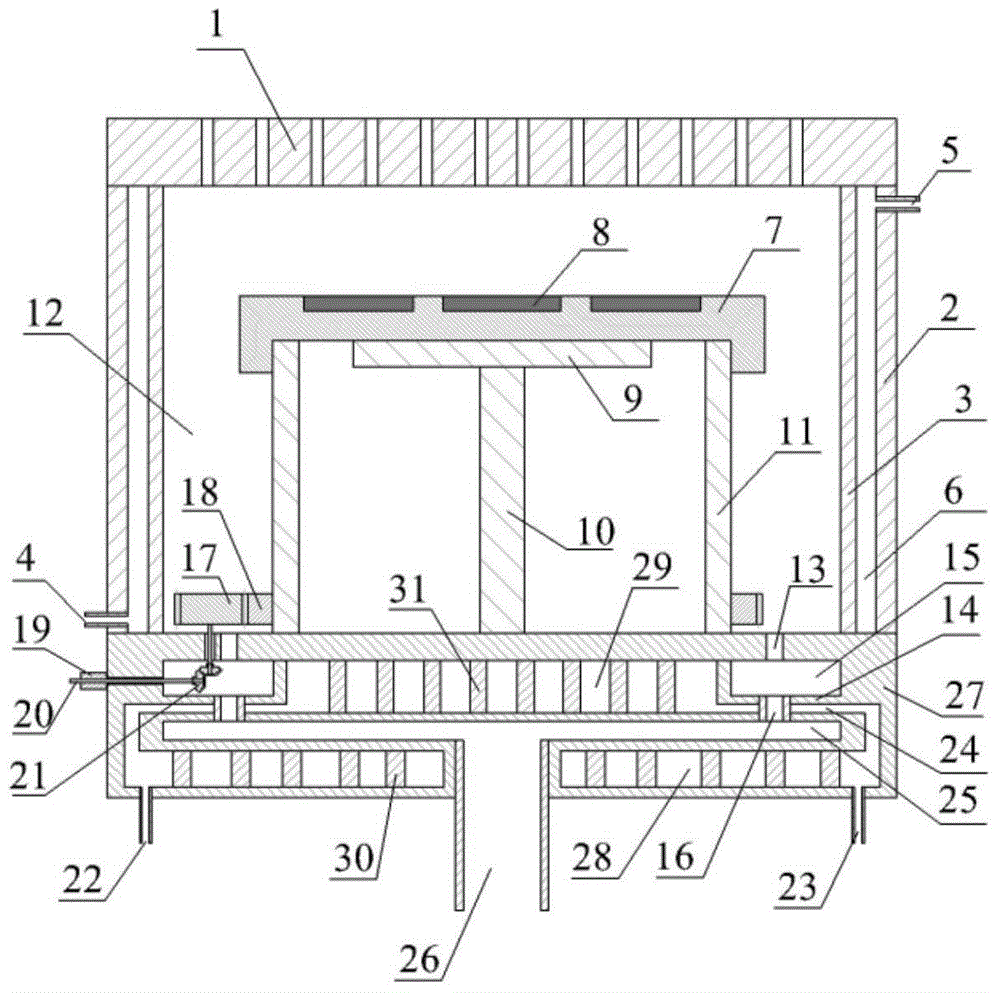

[0024] Same as Embodiment 1, the difference is that some organic molecule coating applications are not heated to generate physical and chemical reactions, but polymers in the gas are condensed and deposited on the substrate. At this time, the heater 9 can be a low-temperature constant temperature temperature control platform, see image 3 As shown, the slide tray 7 can directly and well contact the constant temperature temperature control platform, so that the constant temperature temperature console can control the slide tray 7 at the designed cooling temperature, which is beneficial to the deposition of organic molecules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com