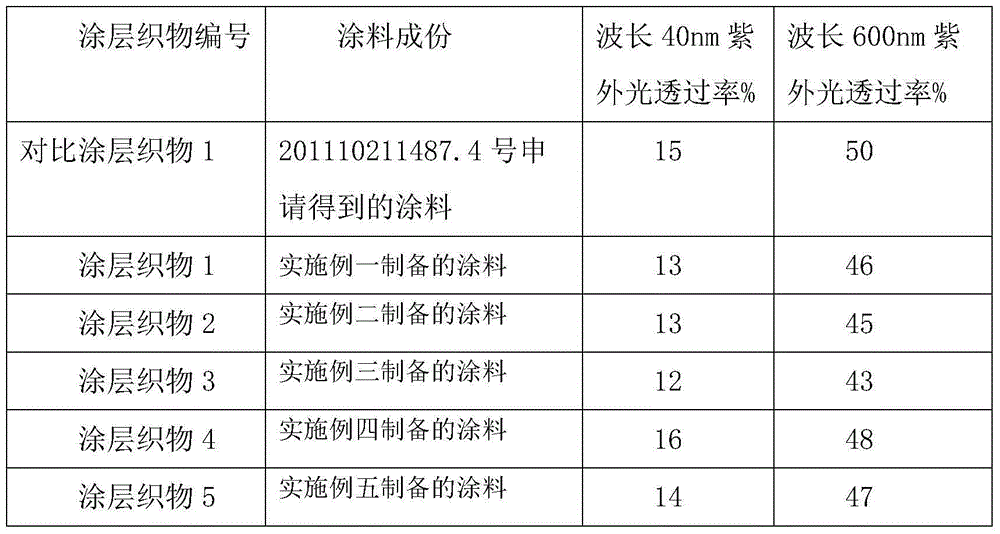

Fabric ultraviolet shielding coating material and preparation method

A coating material and external shielding technology, which is applied in the field of UV shielding coating materials and preparations for fabrics, can solve the problems that the anti-ultraviolet shielding effect needs to be improved and contains harmful components, and achieve good ultraviolet light shielding effect, stability and practicality The effect of good sex and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation method of the ultraviolet shielding coating material for fabric of the present invention, the method comprises the following steps:

[0044] Step 1, the preparation of zinc chloride complex:

[0045] Raw materials by weight percentage: 13% of 2-methylsiloxane oil, 10% of sodium tripolyphosphate, 6% of mannitol, 6% of silicon dioxide, 4% of sodium chloride, and the rest is zinc chloride for batching. Mix 2-methylsiloxane oil and silicon dioxide at room temperature to form a mixture; mix sodium tripolyphosphate (crushed to 10-30 microns), mannitol, zinc chloride, and sodium chloride to form a mixture; The two mixtures are fully stirred to obtain a white powdery zinc chloride complex;

[0046] Step 2, preparation of waste glass powder and waste cement mixed powder:

[0047] 1) First Bi(NO 3 ) 3 ·5H 2 O, Zn(NO 3 ) 2 .6H 2 O and tetraethyl orthosilicate Si(OC 2 h 5 ) 4 Dissolve in absolute ethanol respectively to form three kinds of solutions; the ...

Embodiment 2

[0057] The preparation method of ultraviolet shielding coating material for fabric of the present invention comprises the following steps:

[0058] Step 1, the preparation of zinc chloride complex:

[0059] Raw materials by weight percentage: 15% of 2-methylsiloxane oil, 9% of sodium tripolyphosphate, 8% of mannitol, 7% of silicon dioxide, 5% of sodium chloride, and the rest is zinc chloride for batching. Mix 2-methylsiloxane oil and silicon dioxide at room temperature to form a mixture; mix sodium tripolyphosphate (crushed to 10-30 microns), mannitol, zinc chloride, and sodium chloride to form a mixture; The two mixtures are fully stirred to obtain a white powdery zinc chloride complex;

[0060] Step 2, preparation of waste glass powder and waste cement mixed powder:

[0061] 1) First Bi(NO 3 ) 3 ·5H 2 O, Zn(NO 3 ) 2 .6H 2 O and tetraethyl orthosilicate Si(OC 2 h 5 ) 4 Dissolve in absolute ethanol respectively to form three kinds of solutions; the weight of the thr...

Embodiment 3

[0071] The preparation of the ultraviolet shielding coating material for this example fabric, each composition carries out batching by following weight percentage: polyethylene glycol 4%, polyphenylmethylsiloxane 1.1%, zinc chloride complex 0.4%, hydroxyethyl 0.9% of cellulose, 29% of mixed powder of waste glass powder and waste cement, 9% of water, and the rest is composite water-based resin. All the other preparation processes are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com