Low-temperature waste heat-driven heat and electricity parallel supply method and system implementing same

A low-temperature waste heat and thermoelectric technology, which is applied in the field of waste heat recovery, can solve the problems of reducing energy utilization grade, environmental heat pollution, and waste heat resource waste, so as to avoid heat pollution, meet heat energy demand, and realize the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

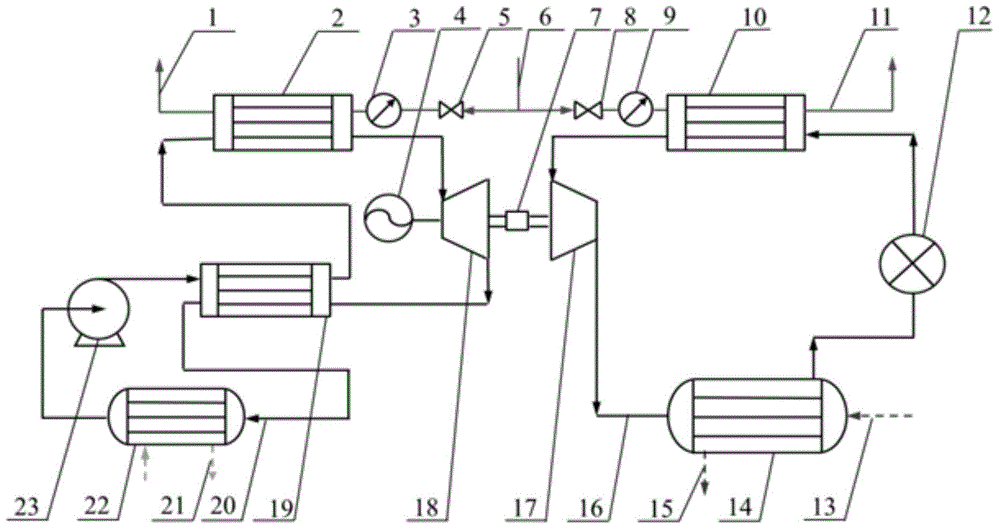

[0032] A thermoelectric co-supply system driven by low temperature waste heat, such as figure 1 As shown, it includes organic Rankine cycle subsystem (ORC system) and heat pump cycle subsystem (HP system).

[0033] The organic Rankine cycle subsystem is composed of generator 2, generator 4, expander 18, regenerator 19, low temperature condenser 22, working fluid pump 23, flow regulating valve 5 and flow meter 3, and the output from generator 2 The pipeline sequentially connects the expander 18, the regenerator 19, the low-temperature condenser 22, the regenerator 19 and the working medium pump 23, and finally returns to the generator 2 to form an organic Rankine cycle. The generator 4 is connected to the expander 18 in transmission, and the pipeline where the first heat flow 1 enters the generator 2 is provided with a first flow regulating valve 5 and a first flow meter 3 . Realize the adjustment of waste heat flow of the organic Rankine cycle subsystem.

[0034] The low tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com