Quantitative measurement apparatus for volume fraction of soot produced by combustion in optical engine cylinder

An optical engine and volume fraction technology, applied in the direction of material excitation analysis, etc., can solve problems such as difficult carbon soot calibration process, achieve the effect of removing sensors and data acquisition devices, simple operation, and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

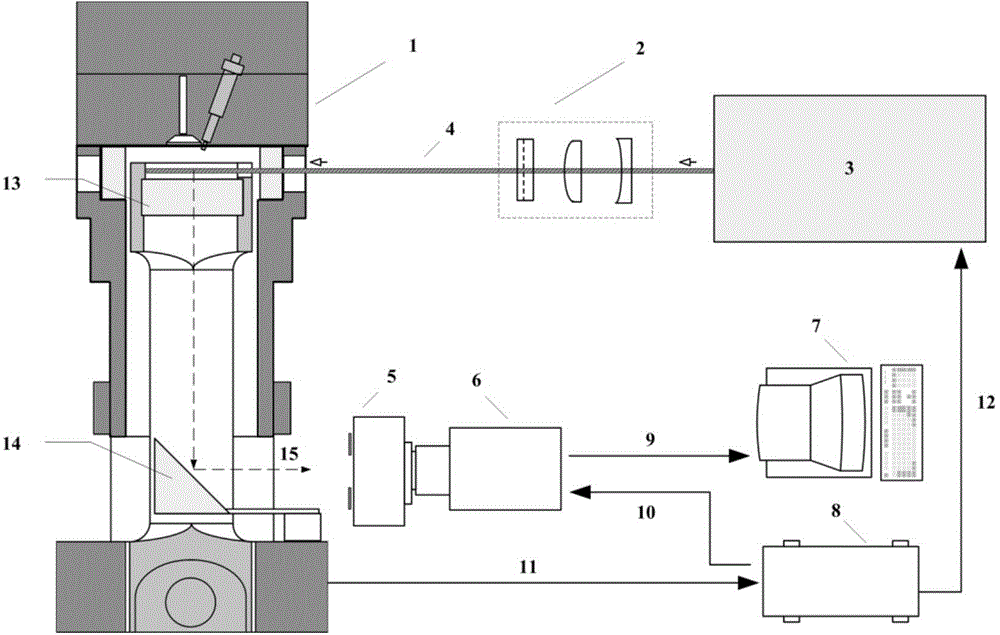

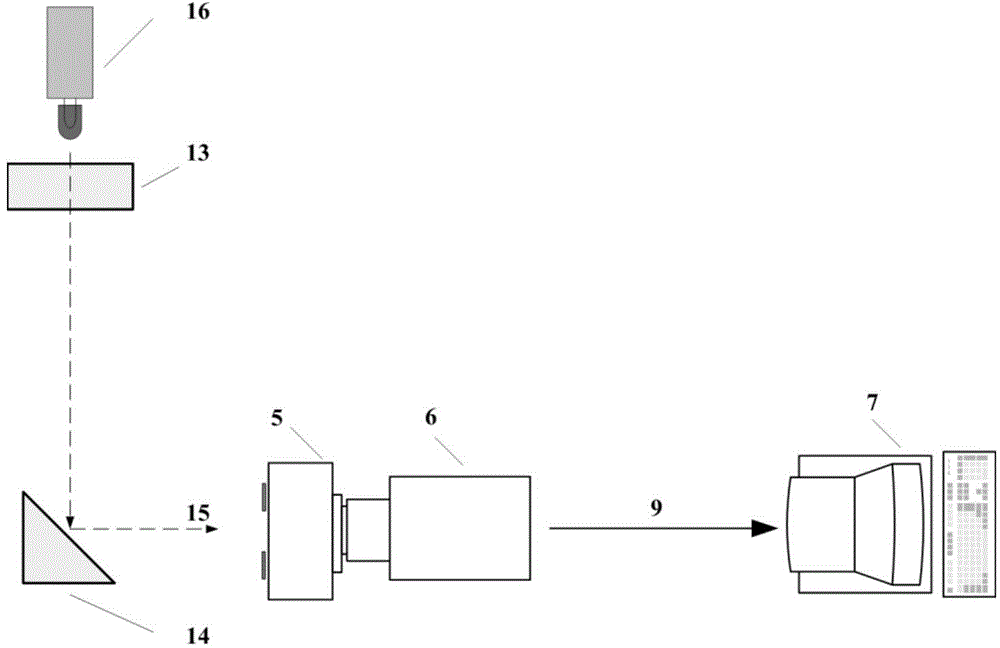

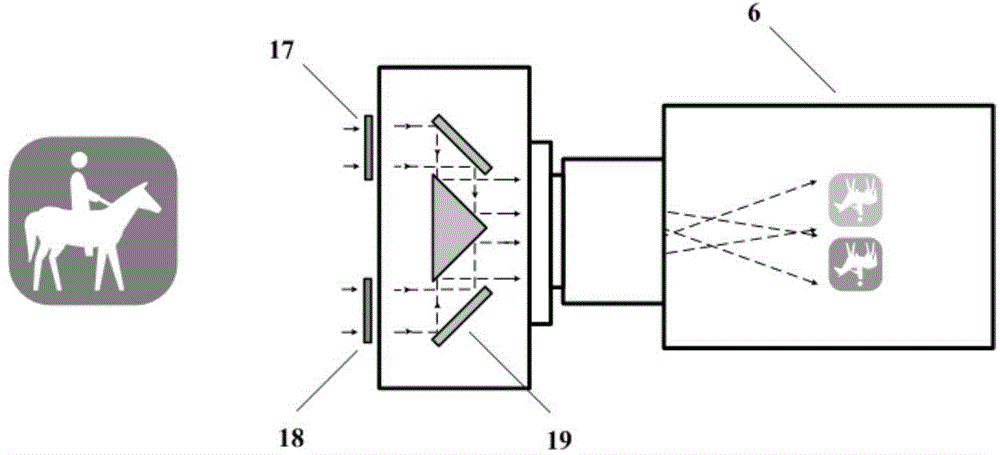

[0035] A quantitative measuring device for the volume fraction of soot in the combustion process of an optical engine cylinder, see figure 1 , figure 2 and image 3 , consists of Nd:YAG laser 3, lens group 2, optical engine 1, dual imaging device 5, standard light source 16, ICCD camera 6, image acquisition system 7 and digital pulse delayer 8. The optical engine 1 is provided with a piston crown quartz window 13 and a reflector 14 .

[0036] The standard light source 16 with known radiation intensity is used to calibrate the radiation intensity of the ICCD camera 6 equipped with the dual imaging device 5 to obtain the sensitivity coefficient of the ICCD camera 6 to the radiation intensity of the illuminant. Nd:YAG laser 3 produces high-energy laser, which forms sheet-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com