Ionic conductivity testing method for ion-electron mixing conductor material

A technology of ionic conductivity and mixed conductors, applied in the direction of material resistance, measuring resistance/reactance/impedance, measuring devices, etc., can solve the problems of inaccurate measurement results, neglect of contact resistance, and influence of measurement results, etc., to avoid inconvenient operation, Reduce the effect of error and the experimental process is simple and easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

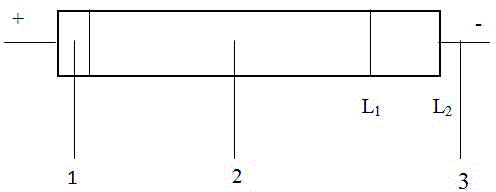

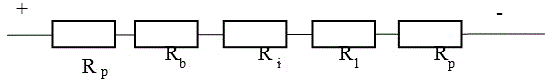

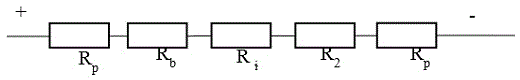

[0020] In this example, see Figure 1 to Figure 4 , a kind of ionic conductivity testing method of ion-electronic mixed conductor material, it is characterized in that, comprises the steps:

[0021] a. After sintering the powder of the ion-electronic mixed conductor material to prepare the mixed conductor material sample 2 of cylindrical strip or cubic strip, measure the size of the mixed conductor material sample 2, and calculate the mixed conductor material sample 2 cross-sectional area S;

[0022] b. use the yttria-stabilized zirconia matrix material with a percentage of substance amount of 8mol% to prepare a strip-shaped blocking electrode 1, the cross-section of the blocking electrode 1 is the same as that of the mixed conductor material sample prepared in a. 2 have the same cross-sectional shape and equal cross-sectional area, so that the end face of the blocking electrode 1 completely covers the end face contacting the mixed conductor material sample 2;

[0023] c. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com