Synchronous pulse exposure method for maskless lithography equipment and digital laser direct-writing system

A maskless lithography, synchronous pulse technology, applied in microlithography exposure equipment, photolithography process exposure devices, etc., can solve problems such as low production capacity and weak system adaptability, and achieve improved contrast, increased contrast, and increased effectiveness. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The scheme of this application is further described in conjunction with the accompanying drawings as follows:

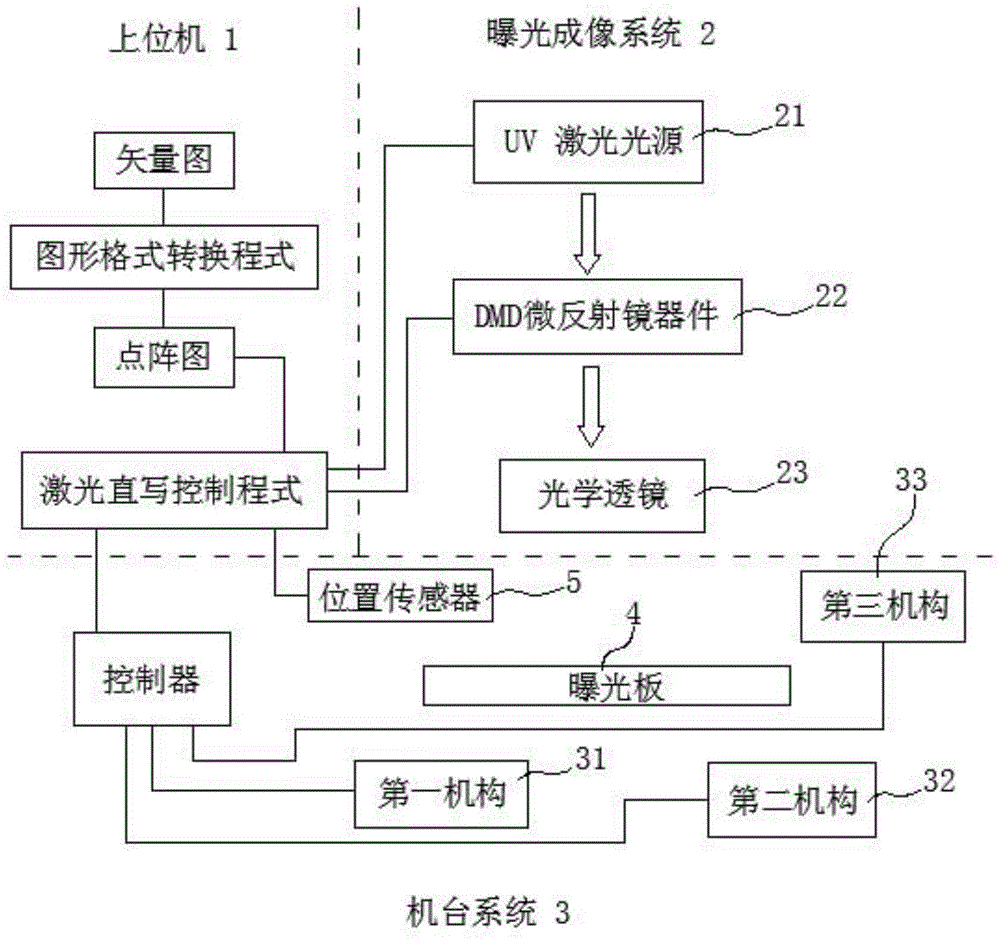

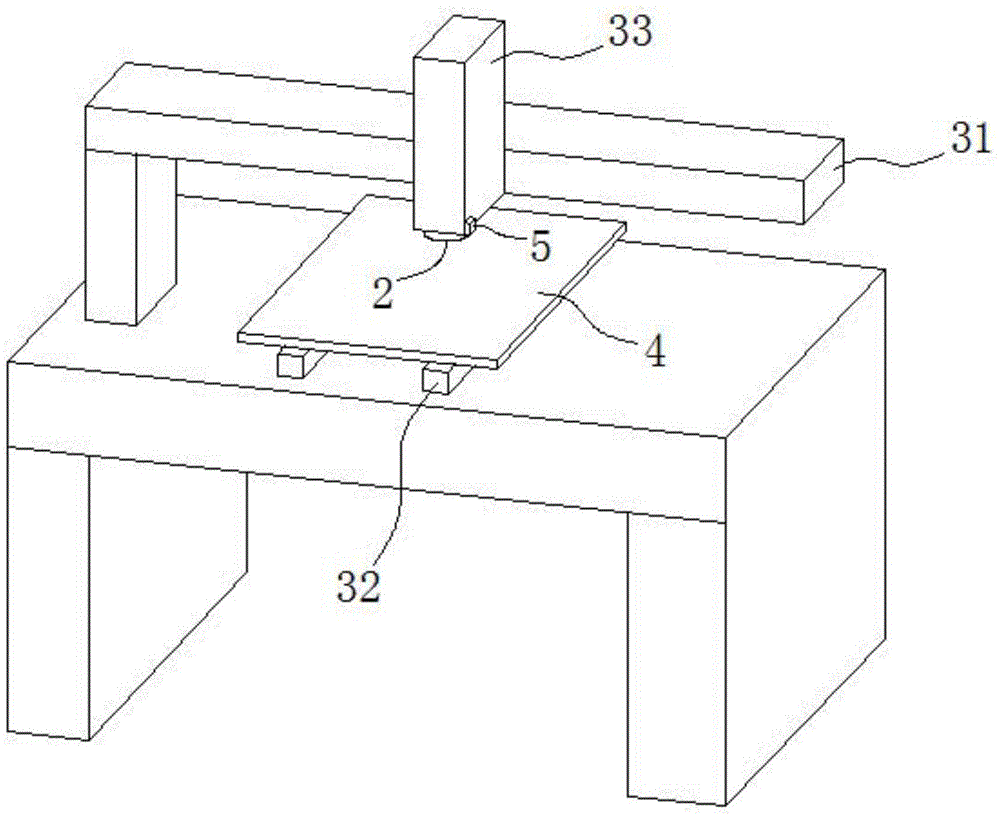

[0026] A kind of synchronous pulse exposure method of maskless lithography equipment, described maskless lithography equipment adopts the exposure imaging system that is made up of UV laser or UV LED light source, DMD micromirror device and optical lens, and described synchronous pulse The exposure method includes the steps of: generating a series of pulse synchronization signals, triggering the DMD micro-mirror device to work synchronously with the UV laser or UV LED light source, and the pulse interval of the pulse synchronization signal depends on the DMD micro-mirror device pairing pattern The replacement or refresh cycle; specifically, when the DMD micro-mirror device opens a new exposure map, the UV laser or UV LED light source is turned on synchronously; when the DMD micro-mirror device is replaced or the process of refreshing the exposure map is turned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com