Miniature X-ray source based on carbon nanotube field emission

A technology of field emission and carbon nanotubes, applied in X-ray tubes, X-ray tube electrodes, X-ray tube target materials, etc. Shortened tube life and other issues, to achieve the effect of easy miniaturization, high efficiency, high emission efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

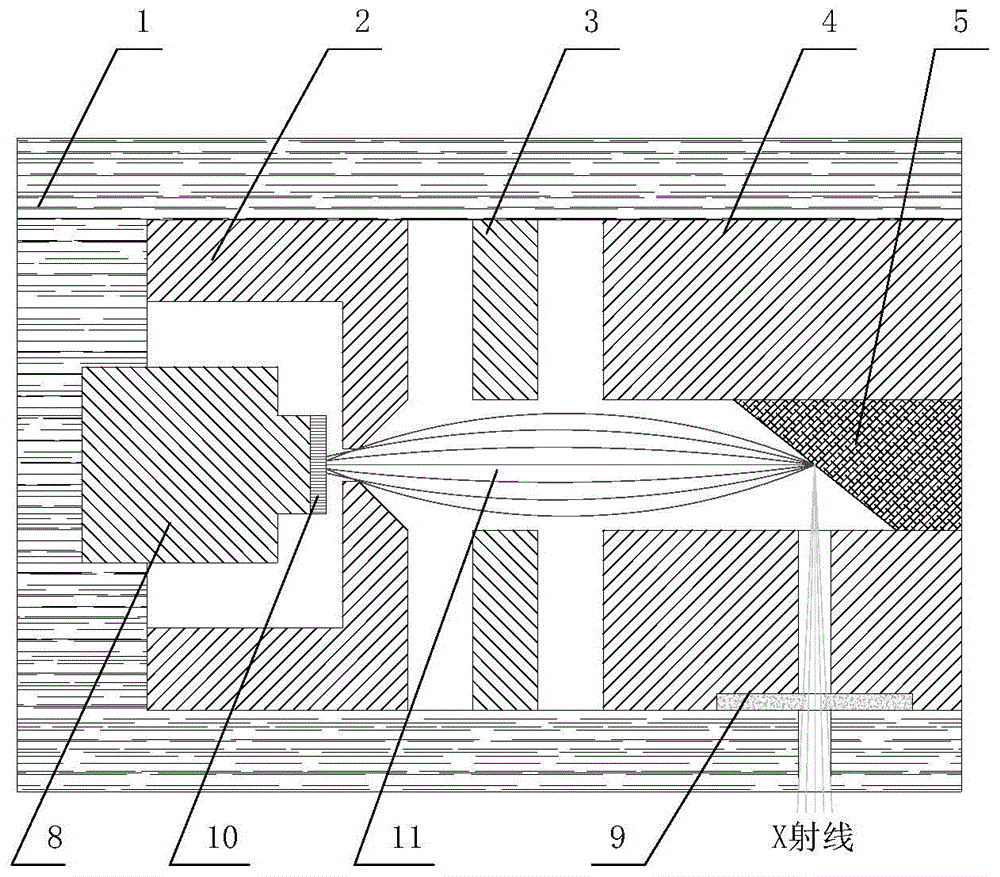

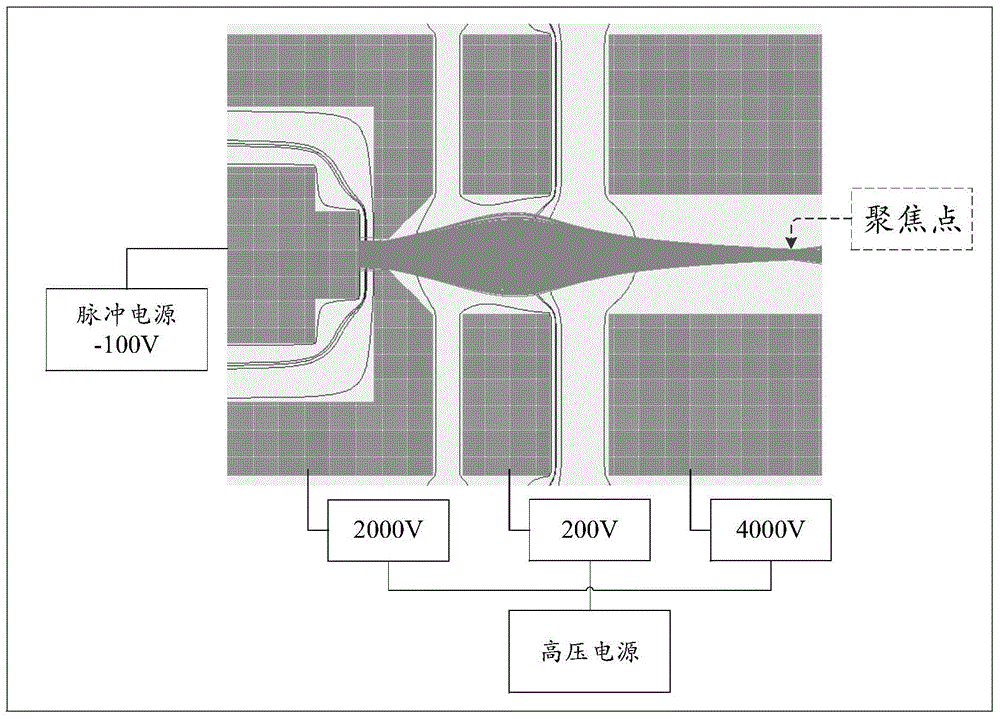

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

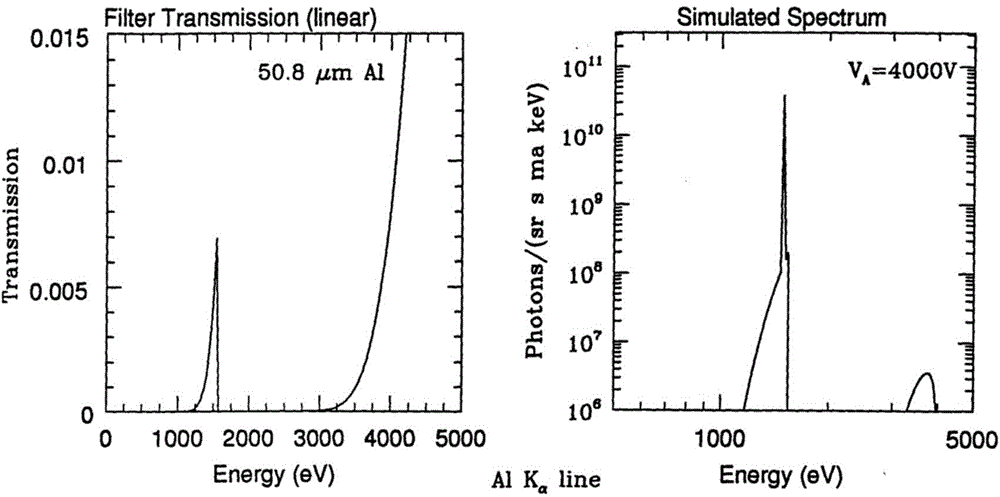

[0026] The purpose of the present invention is to provide a carbon nanotube field emission-based miniature X-ray source for on-orbit calibration of an X-ray pulsar navigation detector. The X-ray tube using the field emission cathode 8 as the electron source generates electron beams by means of field electron emission. Under the action of an external electric field, the height of the surface barrier of the cathode 8 is reduced and the width is narrowed, and a large number of electrons in the emitter Escape through the surface barrier due to quantum tunneling. The field emission cathode 8 has low operating temperature and low power consumption, and it is easy to realize the miniaturization of the X-ray source, and because there is no time delay in field electron emission, the pulsed X-rays generated have extremely high time resolution, which is suitable for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com