Preparation method of low-fat meat balls

A meatball, fat technology, applied in food preparation, food ingredients as taste improver, food science and other directions, to achieve high nutritional value, high elasticity and hardness, and the effect of deepening development and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

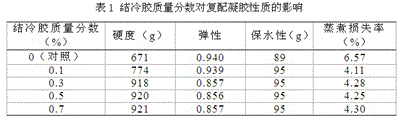

[0024] Gellan gum addition test—the ratio of sodium alginate to gellan gum affects the properties of the compound gel. The mass fraction of sodium alginate is 1%, the dissolution temperature is 60°C, the mass fraction of calcium carbonate is 0.3%, the mass fraction of gluconolactone is 0.6%, and the gelation temperature is 4°C.

[0025] Depend on figure 1 It can be seen that adding gellan gum can increase the gel hardness of the gel system and reduce the gel elasticity. When the amount of gellan gum added was 0.1%, the hardness of the compound gel increased by 103g compared with the control, and the gel elasticity did not decrease significantly. The water retention of the compound gel was further improved after adding gellan gum, and the cooking loss rate was significantly reduced. When the amount of gellan gum added was 0.1%, compared with the control, the gel water retention increased by 6g, and the cooking loss rate decreased by 2.46%.

Embodiment 2

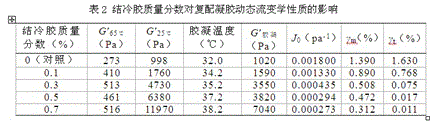

[0027] Dynamic rheology test - evaluate the structural stability of the compound gel by measuring the elastic modulus (G') and gelation temperature at different temperatures.

[0028] Depend on figure 2 It can be seen that the mass fraction of gellan gum affects the elastic modulus of the compound gel at 65°C and 25°C, the gelling temperature and the elastic modulus at the gelling temperature. And with the increase of the proportion of gellan gum, the transition temperature and G'gelling increase significantly. When the mass fraction of gellan gum was 0.1%, G′65℃ and gelling temperature increased most significantly, increasing by 50.2% and 6.9%, respectively. This shows that there is an interaction between sodium alginate and gellan gum.

[0029] The recoverable deformation γm and non-recoverable deformation γt of the composite gel were affected by adding gellan gum. With the increase of the mass fraction of gellan gum, the range of strain recovery of the compound gel decr...

Embodiment 3

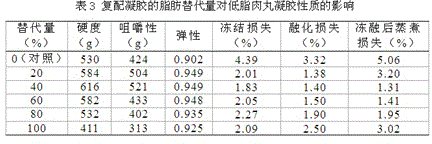

[0031] Fat replacement test - the amount of fat replacement in the compound gel affects the gel properties of low-fat meatballs.

[0032] Depend on image 3 It can be seen that with the increase of the fat replacement amount of the compound gel, the hardness, chewiness and elasticity of the low-fat meatballs all showed a trend of first increasing and then decreasing. When the fat replacement amount of the compound gel is below 60%, the hardness, chewiness and elasticity of the meatballs are significantly improved, and the texture of the meatballs is significantly improved; when the replacement amount exceeds 60%, the hardness and chewiness of the meatballs are low for comparison.

[0033] When the fat replacement amount of the compound gel was 40%-60%, the freeze-thaw loss and cooking loss after freeze-thaw of low-fat meatballs were significantly reduced, and the water retention was significantly enhanced. When the replacement amount of the compound gel exceeded 60%, the fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com