Technological method of solid-wood UV (ultraviolet) veneer

A process method and veneer technology, applied in the jointing of wooden veneers, wood processing equipment, manufacturing tools, etc., can solve the problems of small batch production, large wood consumption, and long cold pressing time, and achieve processing costs Low cost, high production efficiency and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

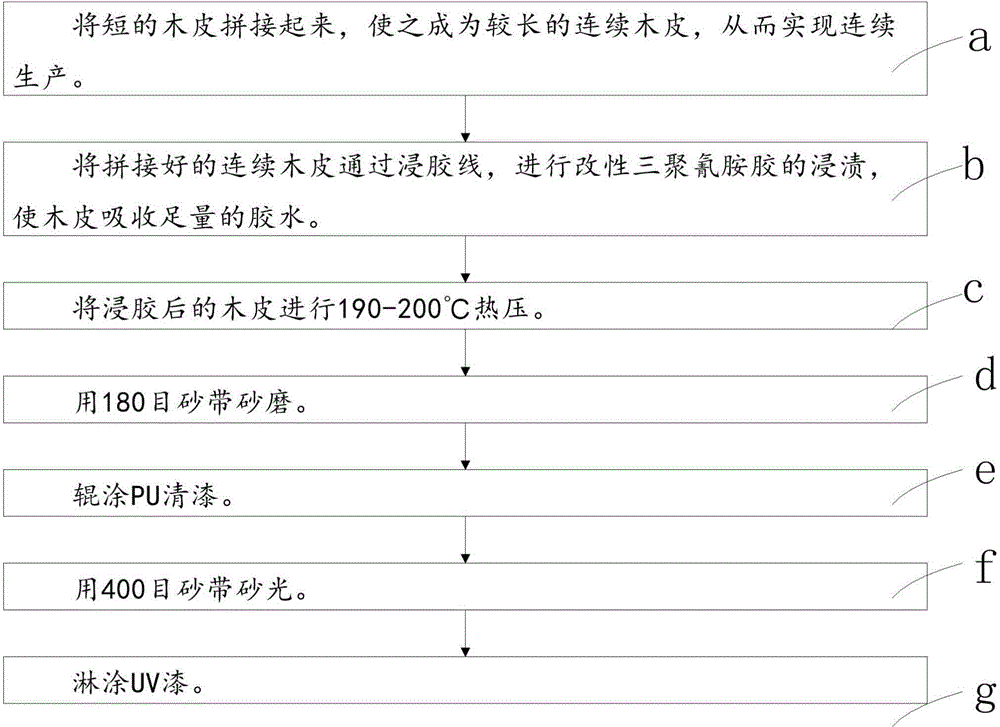

[0018] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

[0019] see figure 1 Shown, it is the process flowchart of solid wood UV veneer of the present invention;

[0020] Step 1: Splicing of solid wood veneers: splicing short veneers together to make them longer continuous veneers, thereby realizing continuous production.

[0021] Due to the limited growth height of trees, the format of solid wood veneer is usually not too long, and the length of veneer that solid wood veneer suppliers can provide is correspondingly short. In order to meet the requirements of batch continuous production, short veneers need to be spliced together to make them longer continuous veneers, rolled into rolls or folded into a pile according to the splicing line, and dipped from one of them during production to achieve continuous veneer. Production.

[0022] Step 2: Glue dipping: P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com