Method for preparing graphene by rotationally shearing in electric field environment

A rotary shearing and graphene technology, applied in the field of graphene preparation, can solve the problems of non-environmentally friendly oxygen-containing functional groups, harsh equipment and equipment requirements, and high growth costs, and achieve the effects of low defect density, low equipment and equipment requirements, and high quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

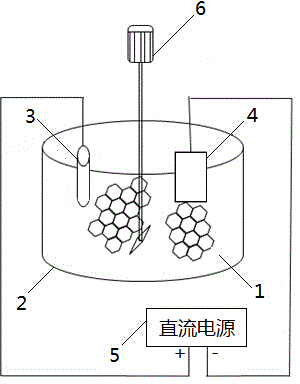

[0034] see figure 1 As shown, a device for preparing graphene by rotating and shearing in an electric field environment includes a reaction vessel 2 containing a lithium ion aqueous solution 1, a high-purity graphite 4 as a cathode, an inert electrode 3 as an anode, a stirrer 6 and a direct current Power supply 5, the inert electrode 3 and the high-purity graphite 4 are all immersed in the lithium ion aqueous solution 1, and the inert electrode 3 and the high-purity graphite 4 are respectively connected to the positive and negative electrodes of the direct current power supply 5 The stirrer 6 is erected above the reaction vessel 2, and the stirring rod of the stirrer 6 vertically extends into the lithium ion aqueous solution 1.

[0035] A method for preparing graphene by rotating and shearing in an electric field environment, using ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com