Method for cleaning aged oil sludge

A technology for sludge and cleaning fluid, applied in the field of environmental remediation, can solve the problems of reducing light components and increasing difficulty, and achieves the effect of good elution rate and great harm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

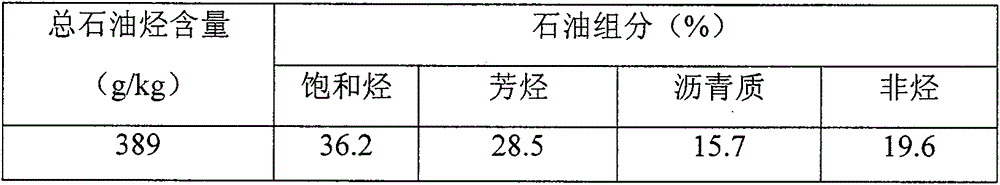

[0012] (1) The aged oil sludge in this example was taken from Dagang Oilfield. The oil sludge was air-dried in a cool and ventilated place, passed through a 2mm sieve to remove impurities, and stored in a sealed bag for later use. Table 1 shows the total petroleum hydrocarbon content in oil sludge, and the content of four components: saturated hydrocarbons, aromatics, asphaltenes, and non-hydrocarbons. It can be seen from the table that the total petroleum hydrocarbon content (TPH) is 389g / kg, of which asphaltenes account for 15.7%, non-hydrocarbons account for 19.6%, the content of heavy components is relatively high, and the aging degree of oil sludge is relatively large.

[0013] Table 1 Oil content of oil sludge in Dagang and the proportion of each component

[0014]

[0015] (2) cleaning of greasy sludge: adopt 150ml beaker as scrubber, add 100ml deionized water, be 5.1% according to total mass concentration, mass ratio is the ratio of 0.1:1:4 to add rhamnolipid 0.1g, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com