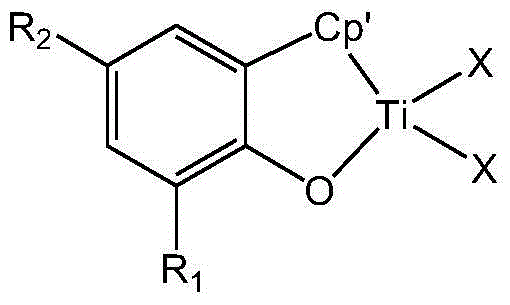

Aryloxy side chain half sandwich titanocene complex having large steric hindrance and application thereof

A technology of aryloxy and complexes, applied in the field of olefin polymerization catalysts, can solve the problems of low polyethylene molecular weight and failure to meet the requirements, and achieve the effects of good copolymerization performance, stable structure and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

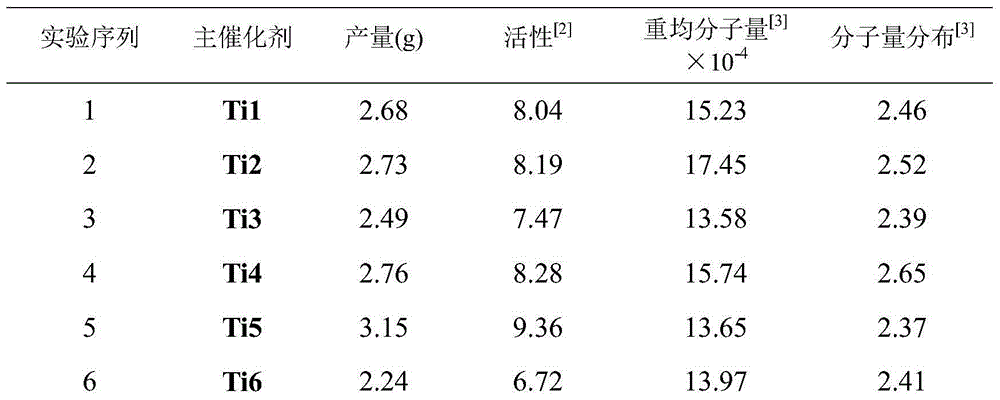

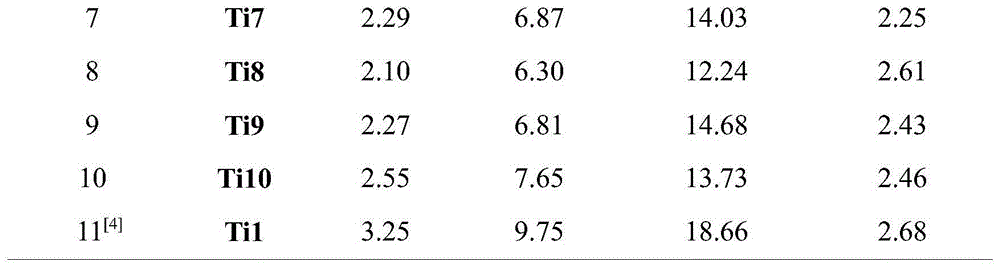

Examples

Embodiment 1

[0032] Embodiment 1, the preparation of complex Ti1

[0033] Under an inert atmosphere, room temperature and stirring conditions, 0.81 mL of TiCl with a concentration of 2.0 mol / L 4 The toluene solution was slowly added to the 10ml toluene solution containing 1.6mmol 2-(2,3,4,5-tetramethylcyclopentadiene)-4-tert-butyl-6-tritylphenol, and the reaction temperature Raise to 70°C, react for 2 hours, filter out insoluble matter, and evaporate the solvent to dryness under reduced pressure to obtain a crude product. The crude product was ultrasonically washed with a small amount of hexane solvent, and after filtration, the solvent was dried on a vacuum line to obtain 0.58 g of a dark red solid product with a yield of 57%. Labeled Ti1.

Embodiment 2

[0034] Embodiment 2, the preparation of complex Ti2

[0035] Under an inert atmosphere, room temperature and stirring conditions, 0.56 mL of TiCl with a concentration of 2.0 mol / L 4Slowly add the toluene solution into the 10ml toluene solution containing 1.1mmol 2-(2,3,4,5-tetramethylcyclopentadiene)-4-tert-butyl-6-tri(p-tolyl)methylphenol , the reaction temperature was raised to 70°C, and the insoluble matter was filtered off after 2 hours of reaction, and the solvent was evaporated to dryness under reduced pressure to obtain a crude product. The crude product was ultrasonically washed with a small amount of hexane solvent, filtered, and the solvent was dried on a vacuum line to obtain 0.49 g of an orange-red solid product with a yield of 64%. Marked as Ti2.

Embodiment 3

[0036] Embodiment 3, the preparation of complex Ti3

[0037] Under an inert atmosphere, room temperature and stirring conditions, 0.82 mL of TiCl with a concentration of 2.0 mol / L 4 The toluene solution was slowly added to 10ml of 1.6mmol 2-(2,3,4,5-tetramethylcyclopentadiene)-4-tert-butyl-6-(1,1-diphenyl)butylphenol In the toluene solution, the reaction temperature was raised to 70° C., and the insoluble matter was filtered off after 2 hours of reaction, and the solvent was evaporated to dryness under reduced pressure to obtain a crude product. The crude product was ultrasonically washed with a small amount of hexane solvent, filtered, and the solvent was dried on a vacuum line to obtain 0.51 g of an orange-red solid product with a yield of 54%. Marked as Ti3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com