Method for preparing non-smooth surface of alloy substrate

A non-smooth surface and alloy matrix technology, applied in the field of laser processing, can solve the problems of insignificant improvement of matrix performance, shallow implantation depth, and failure to meet the requirements of use, so as to enhance the adsorption of nanoparticles, improve hardness, and friction and wear properties. and the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] The invention provides a novel method for preparing a nano-carbon-based film on the surface of an alloy substrate. The specific steps are:

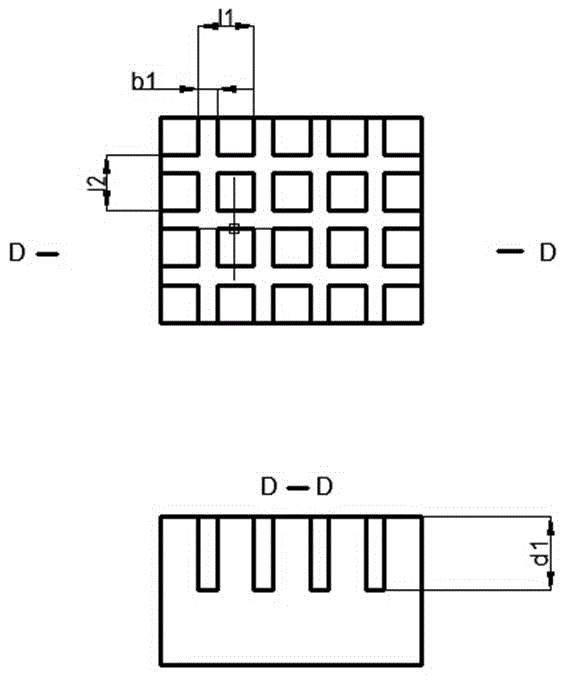

[0027] (1) Laser engrave the width b in the area to be processed on the surface of the workpiece 6 1 , deep d 1 slots, the horizontal and vertical intervals are l 1 , l 2 , forming a grid-like structure.

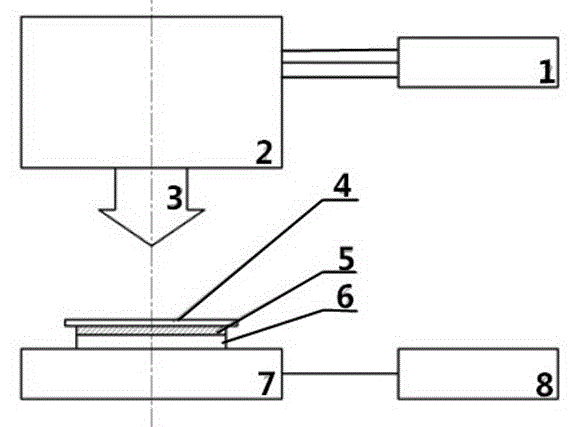

[0028] (2) Inject nanoparticles into the grid grooves, cover the surface of the substrate with an absorbing layer 5 and a constraining layer 4 , and install it on a five-axis workbench 7 .

[0029] (3) The parameters of the laser 2 are set by the laser control device 1 .

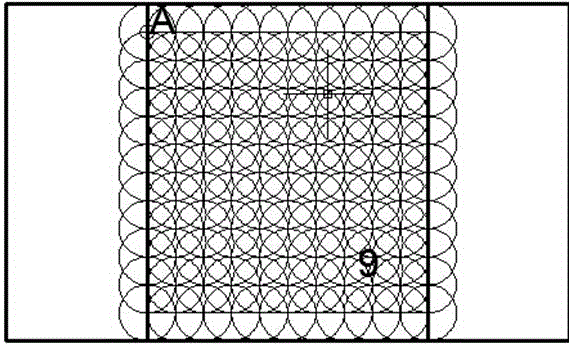

[0030] (4) Adjust the five-axis table 7 through the numerical control system 8 so that the center of the light spot coincides with the upper left corner of the area to be impacted at point A, and make the X-axis and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com