A method for suppressing the initiation and propagation of cracks in parts based on laser shock strengthening

A laser shock strengthening and parts technology, applied in the fields of aviation and automobile industry parts, can solve the problems of changing the metallographic structure of the melting area of the parts, the fatigue life of the parts cannot be well guaranteed, and the metallographic structure of the cladding layer is difficult. , to achieve the effect of green repair and life extension technology, improve service life, and prevent the initiation of micro-cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

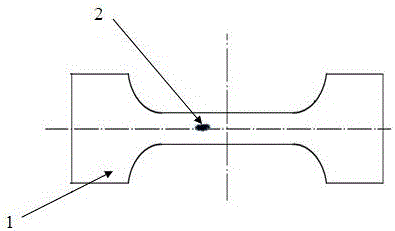

[0031] In this embodiment, the metal part is a 6082 aluminum alloy standard tension-compression fatigue sample with a length of 55 mm and a thickness of 3 mm, with a scratch damage of 0.1 mm in length;

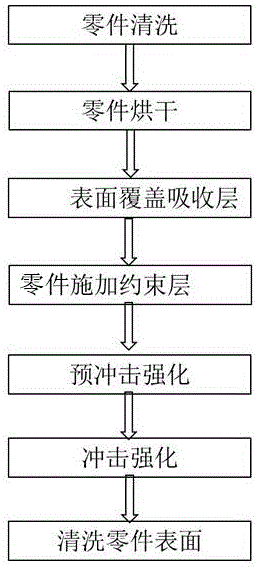

[0032] In this implementation, the crack initiation and propagation of parts are suppressed according to the following steps:

[0033] (1) Clean the aluminum alloy metal parts with damage points with deionized water, then dry them with dry nitrogen, and dry them in a drying oven at 100°C for 10 minutes;

[0034] (2) Surface pretreatment of metal parts. The surface pretreatment of metal parts is to put the metal parts into an ultrasonic cleaning machine equipped with deionized water at a water temperature of 20°C. Blow dry with dry nitrogen, and then put it in a drying oven at 70°C for 20 minutes; in the clean room, cover a layer of black tape with a thickness of 120 μm around the damaged point of the metal part as an absorbing layer;

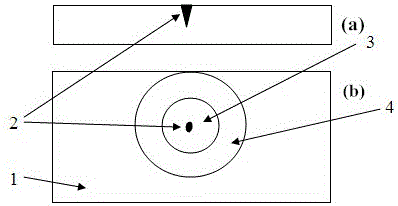

[0035] (3) Install the metal parts cover...

Embodiment 2

[0039] The metal part of this embodiment is a 6082 aluminum alloy standard tension-compression fatigue sample with a length of 55 mm and a thickness of 3 mm, with a notch damage of 0.05×0.05×0.05 mm in size;

[0040] In this implementation, the crack initiation and propagation of parts are suppressed according to the following steps:

[0041] (1) Clean the aluminum alloy metal parts with damage points with deionized water, then dry them with dry nitrogen, and dry them in a drying oven at 100°C for 10 minutes;

[0042] (2) Perform surface pretreatment on metal parts. The surface pretreatment of metal parts is to put the metal parts into an ultrasonic cleaning machine equipped with deionized water at a water temperature of 24°C. Blow dry with dry nitrogen, and then put it in a drying oven at 70°C for 20 minutes; in the clean room, cover a layer of black tape with a thickness of 100 μm around the damaged point of the metal part as an absorbing layer;

[0043] (3) Install the metal...

Embodiment 3

[0047] The metal part in this embodiment is a 6082 aluminum alloy standard tension-compression fatigue sample with a length of 55 mm and a thickness of 3 mm, and has a pit with a diameter of 0.09 mm and a depth of 1 mm;

[0048] In this implementation, the crack initiation and propagation of parts are suppressed according to the following steps:

[0049] (1) Clean the aluminum alloy metal parts with damage points with deionized water, then dry them with dry nitrogen, and dry them in a drying oven at 100°C for 10 minutes;

[0050] (2) Perform surface pretreatment on metal parts. The surface pretreatment of metal parts is to put the metal parts into an ultrasonic cleaning machine equipped with deionized water at a water temperature of 22°C. Blow dry with dry nitrogen, and then put it in a drying oven at 70°C for 20 minutes; in the clean room, cover a layer of black tape with a thickness of 200 μm around the damaged point of the metal part as an absorbing layer;

[0051] (3) Ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com