Combined intelligent isolation bearing of magnetorheological elastomer

A magnetorheological elastomer, vibration isolation bearing technology, applied in the direction of springs/shock absorbers, springs, shock absorbers, etc., can solve the problems of aggravating magnetic flux leakage, increasing bearing gap, influence, etc., to achieve the use and maintenance. Effects of cost reduction, uniform magnetic field distribution, and size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

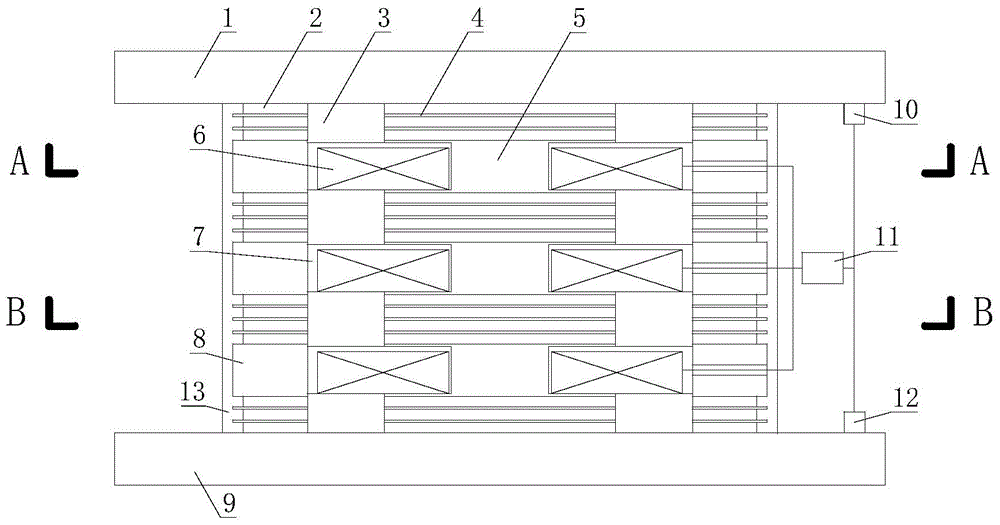

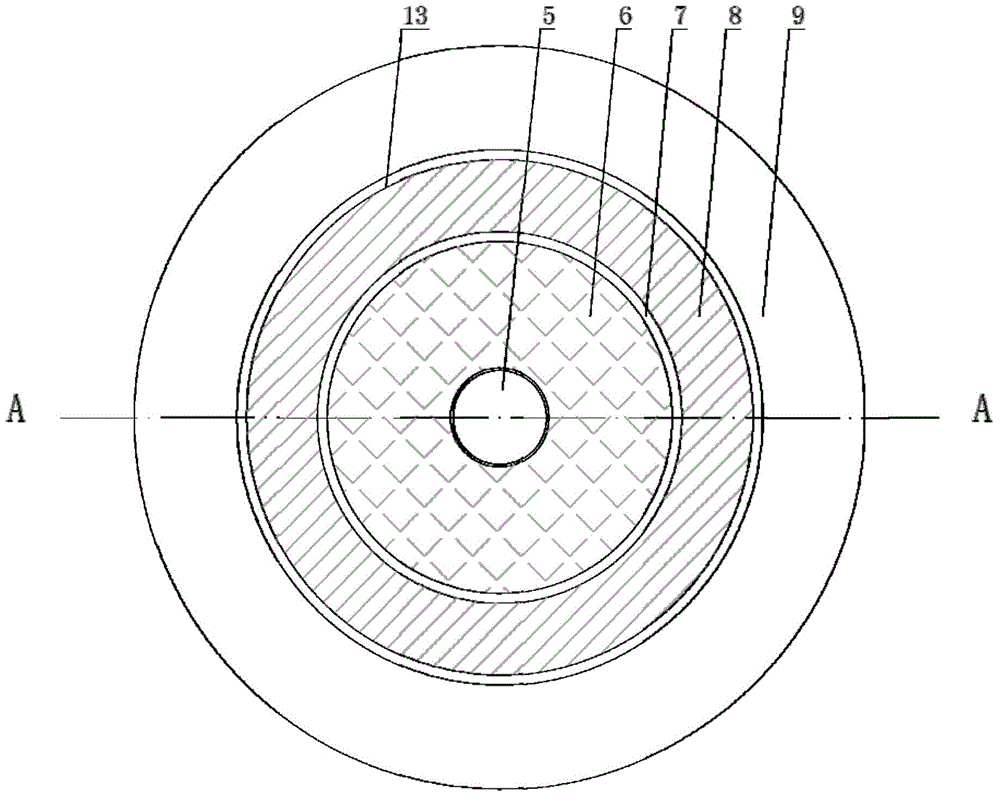

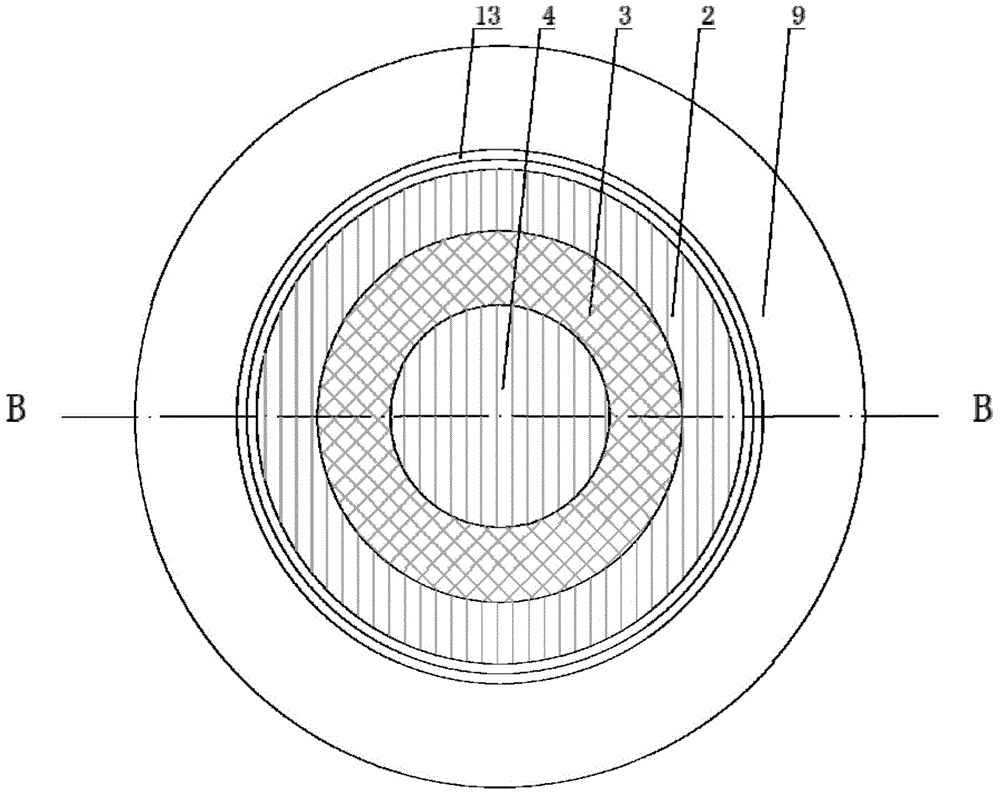

[0022] The specific embodiment of the present invention sees Figure 1 to Figure 3 . from vertical section figure 1 It can be seen that this embodiment is composed of 4 force bearing subassemblies, 3 excitation subassemblies, 2 sensors 10, 12 and 1 controller 11. The two force-bearing subassemblies connected to the upper connecting plate 1 and the lower connecting plate 9 are formed by overlapping and vulcanizing three layers of magnetorheological elastomers and two layers of steel plates, and are vulcanized and stacked on the circular magnetorheological elastomers-steel plates 4 and annular magnetorheological elastomer-steel plate vulcanization lamination 2 are filled with annular lead core 3; the middle two sub-assemblies are composed of four layers of magnetorheological elastomer and three layers of steel plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com