Balance container system capable of online setting and checking and online setting and checking method

A technology for balancing containers and differential pressure transmitters, which is applied to components of steam boilers, indicators of boiler working conditions, steam boiler accessories, etc. It can solve problems that affect the progress of commissioning and acceptance, waste manpower, etc., and achieve saving in setting and calibration The effect of reducing time, reducing work intensity, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

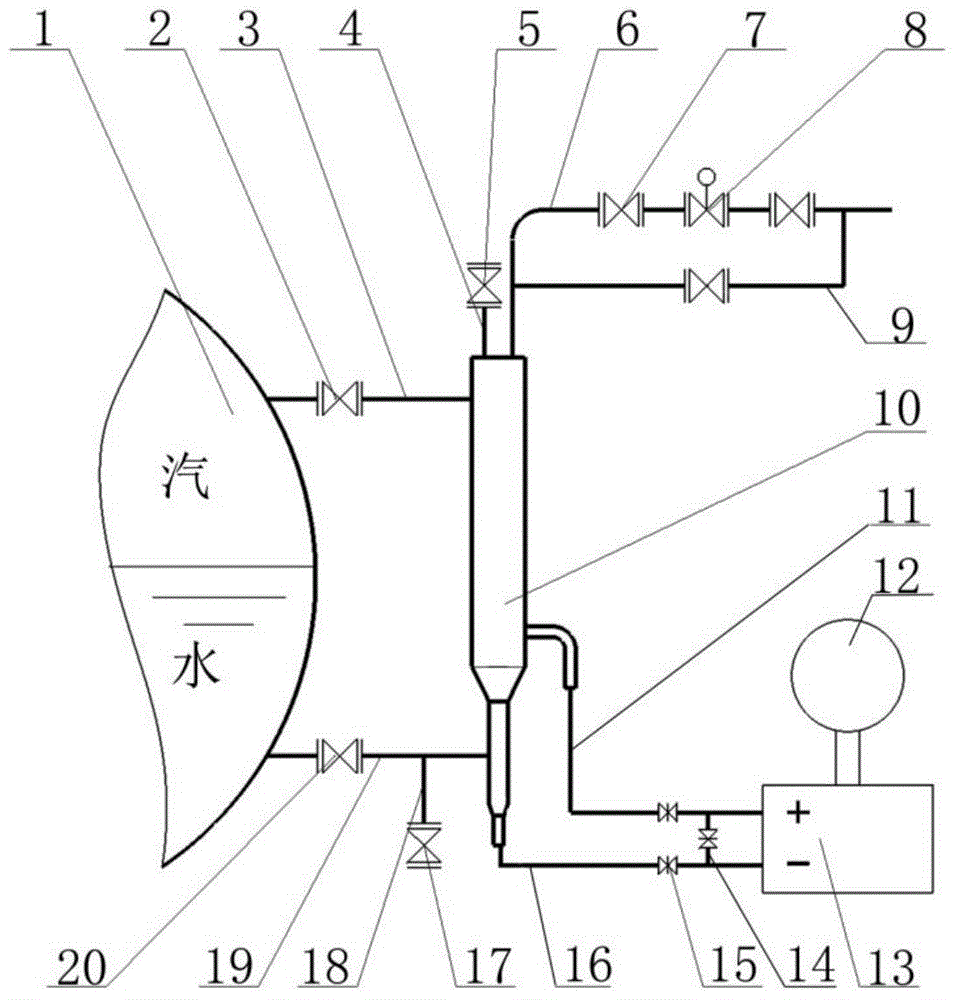

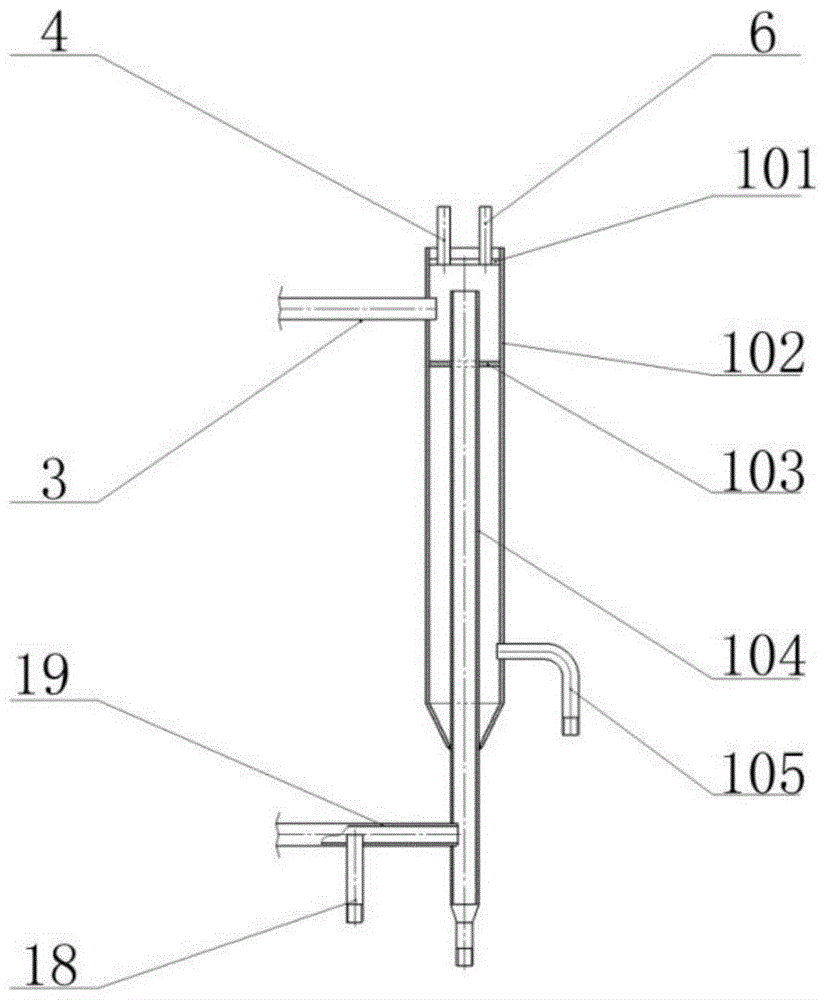

[0028] See figure 1 , is a structural schematic diagram of the balance container system of the present invention, the balance container system that can be adjusted and verified online in the present invention includes the balance of connecting the steam space and the water space of the steam drum 1 through the steam connection pipe 3 and the water connection pipe 19 respectively The container 10, the differential pressure transmitter 13 connected to the balance container 10, the differential pressure transmitter 13 is additionally connected to the boiler control system 12; the upper part of the balance container cylinder 102 is vertically provided with a water supply pipe 6 and a vent pipe 4, and the water Connecting pipe 19 is vertically provided with school water pipe 6 through the tee, and the height of the lower end surface of replenishment pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com