Method for soilless simple rice seedling raising of machine-transplanted rice

A simple machine-transplanted rice technology, applied in the field of seedling cultivation, can solve the problems of high rate of loose seedlings in transplanting small seedlings, unsatisfactory lifting and transportation of seedlings, and inability of seedlings to form lumps, so as to reduce the cost of seedling raising, Improve fertilizer use efficiency and benefit root growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

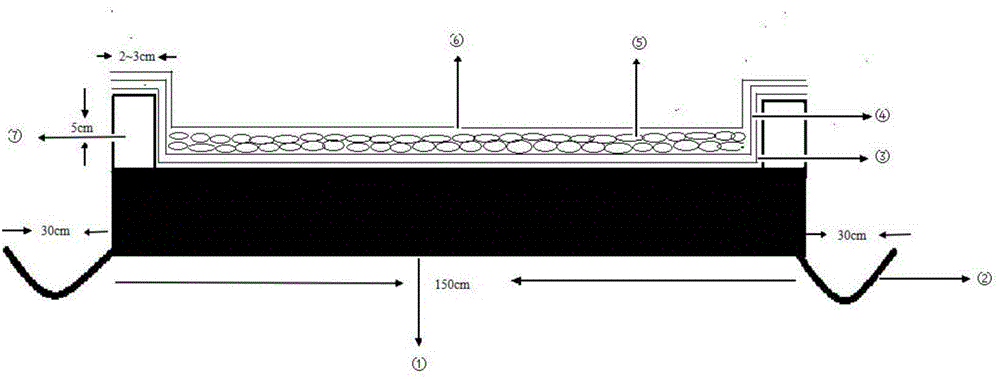

[0040] (1) Seedling plate preparation: use commercially available rice, according to the rice seedling ratio of 1:100 for conventional rice varieties, and 1:130 for hybrid rice varieties, leaving enough seedling field area. Take 150cm seedling boards, the length of the furrow can be adjusted according to the actual conditions of the reserved seedling fields, and a drainage ditch with a width of 30 cm and a depth of 15 cm is reserved between the seedling boards. The seedling field is plowed and stubble removed in advance, and the seedling board is carefully made 10 days before sowing. In order to make the surface of the seedling board smooth, it can be leveled by watering it first. Fill up the high and fill the low, fill the cracks, and make the board fully solid, so that the board surface can be "solid, flat, smooth and straight";

[0041] (2) Laying frame: make a frame with a width of 3cm, a height of 5cm, and a length of 300cm with a hard strip, and lay the frame on the edge...

Embodiment 2

[0050] (1) Seedling board preparation: use commercially available rice, according to the rice seedling ratio of conventional rice varieties 1:80, hybrid rice varieties rice seedling ratio 1:120, leave enough seedling field area, take a 60cm seedling board, the furrow length can be according to the reserved The actual condition of the seedling field is adjusted, and a drainage ditch with a width of 20 cm and a depth of 14 cm is reserved between the seedling boards. The seedling field is plowed and stubble removed in advance, and the seedling board is carefully made 10 days before sowing. In order to make the surface of the seedling board smooth, it can be leveled by watering it first. Fill up the high and fill the low, fill the cracks, and make the board fully solid, so that the board surface can be "solid, flat, smooth and straight";

[0051] (2) laying frame: make the frame of wide 3cm, high 5cm, long 300cm with hard strip, frame is laid on seedling board;

[0052] (3) Lay t...

Embodiment 3

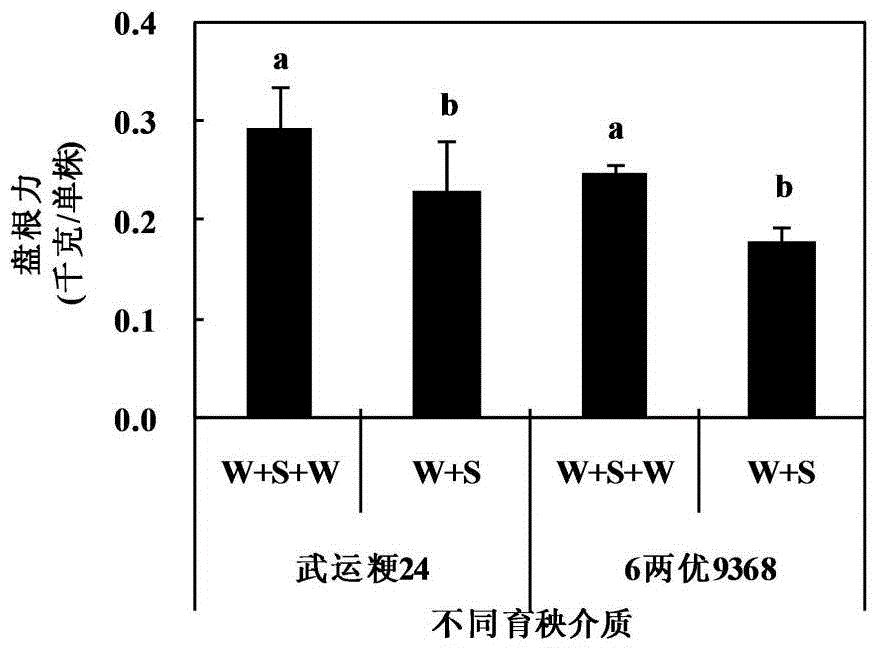

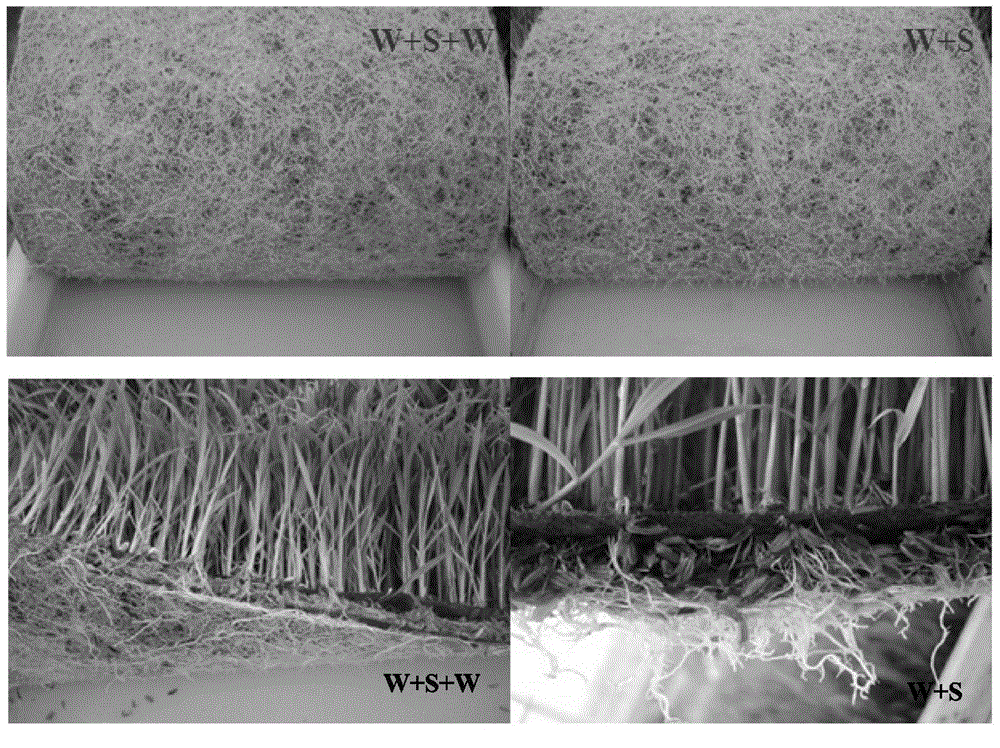

[0060] Seedling packing force and weight comparison

[0061] 1. Materials and methods

[0062] 1) Test location: The test was carried out at the Danyang Experimental Base of Nanjing Agricultural University (32°00′N, 119°32′E, 7m asl) from 2013 to 2014.

[0063] 2) Selection of rice varieties: the conventional japonica rice Wuyunjing 24 and the hybrid indica rice 6 Liangyou 9368 were used as test materials, and the thousand-grain weights were 27g and 28g, respectively. Seed quality should comply with the provisions of GB4404.1.

[0064] 3) Experimental design

[0065] Experiment 1 (comparison of seedling packing force): treatment 1 uses non-woven fabric + rice husk + non-woven fabric as seedling-raising medium, marked as W+S+W group; treatment 2 uses non-woven fabric + rice husk as seedling-raising medium, marked It is W+S group. W+S+W group uses 25g / m2 black spunbonded nonwoven fabric as the medium for the lower nonwoven fabric (below the rice husk), and 20g / m2 black spunb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com