A Method for Adjusting Clearance of Double Row Tapered Roller Bearing in Universal Rolling Mill

A technology of tapered roller bearings and universal rolling mills, which is applied in the direction of metal rolling, metal rolling, and keeping roll equipment in an effective state, which can solve the problems of uneven bearing wear, unevenness, shutdown accidents, etc., and reduce the consumption of spare parts and production costs, increase labor productivity, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

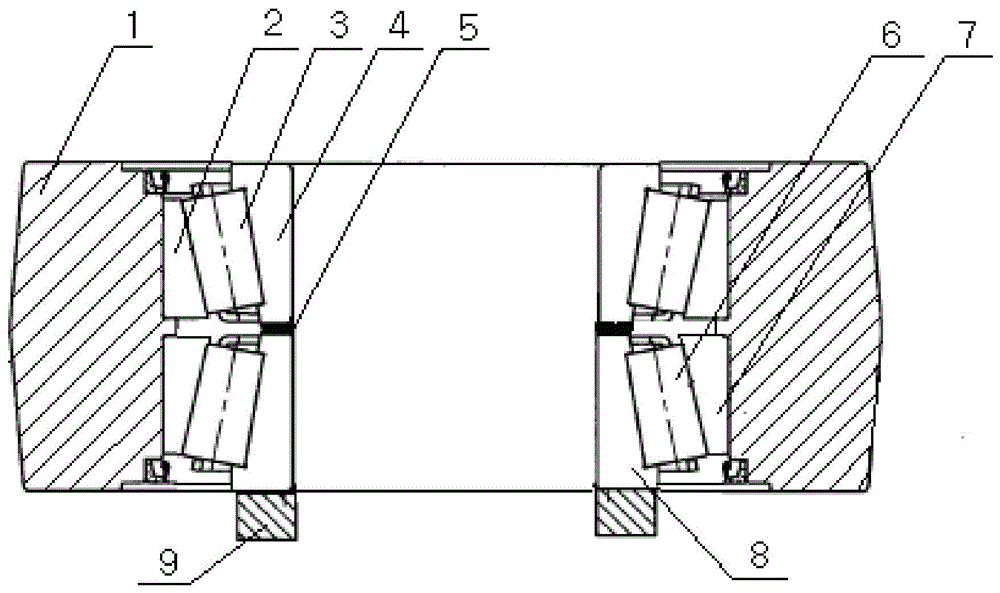

[0020] Depend on figure 1 It can be seen that the double-row tapered roller bearing of the universal rolling mill includes the bearing 3 listed above and the bearing 6 listed below. The specific steps of the method for adjusting the clearance of the universal rolling mill double-row tapered roller bearing of the present invention are as follows:

[0021] 1. Put the vertical roller 1 in the oil tank and heat it to 80-100°C, then place the following bearing outer ring 7 on the bearing support ring. Hang the vertical roller 1 out of the oil tank again, wipe off the grease on the inner surface of the vertical roller, then install the vertical roller 1 on the following bearing outer ring 7, and then install the upper bearing outer ring 2 on the vertical roller 1.

[0022] 2. Put the vertical roller support ring and the wooden support on the bearing outer ring 2 listed above, and then press the rest of the vertical rollers as heavy objects on the wooden support, so that the gap bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com