Method for preparing silver/silver sulfide nanowire with core shell structure

A core-shell structure, nanowire technology, applied in the field of photoelectrochemistry, can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A certain amount of polyvinylpyrrolidone was weighed, dissolved in secondary water, and silver nanowires were dispersed therein (the molar ratio of polyvinyl monomer to silver nanowires was 3:1). To prepare the ferric chloride solution, slowly add the ferric chloride solution (the molar ratio of ferric chloride to silver is 1:1) dropwise into the mixture. After continuing to stir for 30 min, centrifuge and wash 3 times with secondary water. Then take the same amount of polyvinylpyrrolidone and fully dissolve it in water, and evenly disperse the nanowires converted into silver silver chloride, slowly add sodium sulfide solution (half of the molar amount of ferric chloride) dropwise, react for 30min and then centrifuge and wash. Disperse in 60mL of water, put into 180℃ oven for 12h. After the end, take out and wash by centrifugation to obtain silver silver sulfide nanowires.

example 1

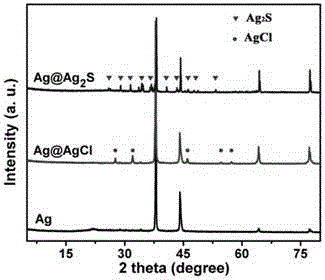

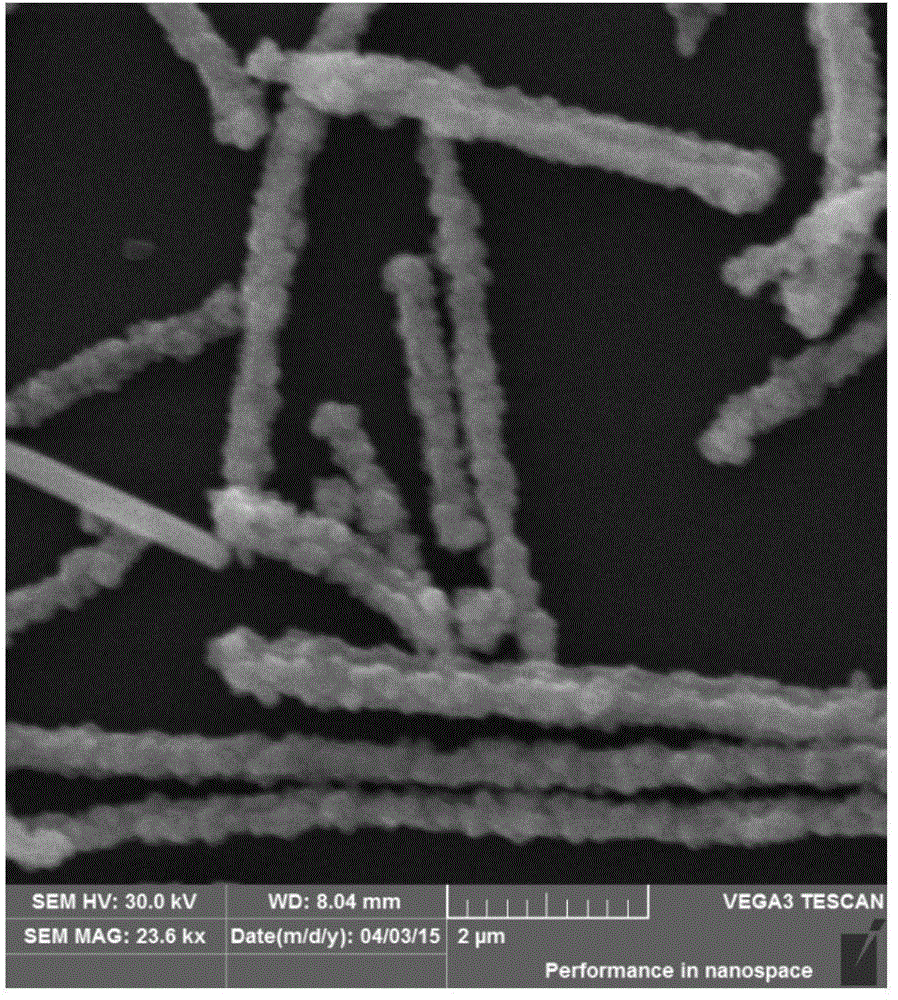

[0017] The scanning electron micrograph of the silver sulfide nanowire of example 1 gained is as figure 1 . It can be seen from the figure that the morphology of the obtained silver silver sulfide nanowires is relatively uniform, the length is 5-10 μm, and the surface becomes rough due to the reaction. Its composition changes can be seen from the XRD pattern ( figure 2 ), silver nanowires were oxidized by ferric chloride and converted to silver silver chloride, and then replaced with sufficient sodium sulfide to form silver silver sulfide.

Embodiment 2

[0019] A certain amount of polyvinylpyrrolidone was weighed, dissolved in secondary water, and silver nanowires were dispersed therein (the molar ratio of polyvinyl monomer to silver nanowires was 3:1). To prepare the ferric chloride solution, slowly add the ferric chloride solution (the molar ratio of ferric chloride to silver is 1:2) dropwise into the mixture. After continuing to stir for 30 min, centrifuge and wash 3 times with secondary water. Then take the same amount of polyvinylpyrrolidone and fully dissolve it in water, and evenly disperse the nanowires converted into silver silver chloride, slowly add sodium sulfide solution (half of the molar amount of ferric chloride) dropwise, react for 30min and then centrifuge and wash. Disperse in 60mL of water, put into 180℃ oven for 12h. After the end, take out and wash by centrifugation to obtain silver silver sulfide nanowires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com