Method for extracting copper, gold and silver from copper oxide ore

A technology for oxidizing copper ore and ore, applied in the field of copper concentrate, can solve the problems of long production line and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

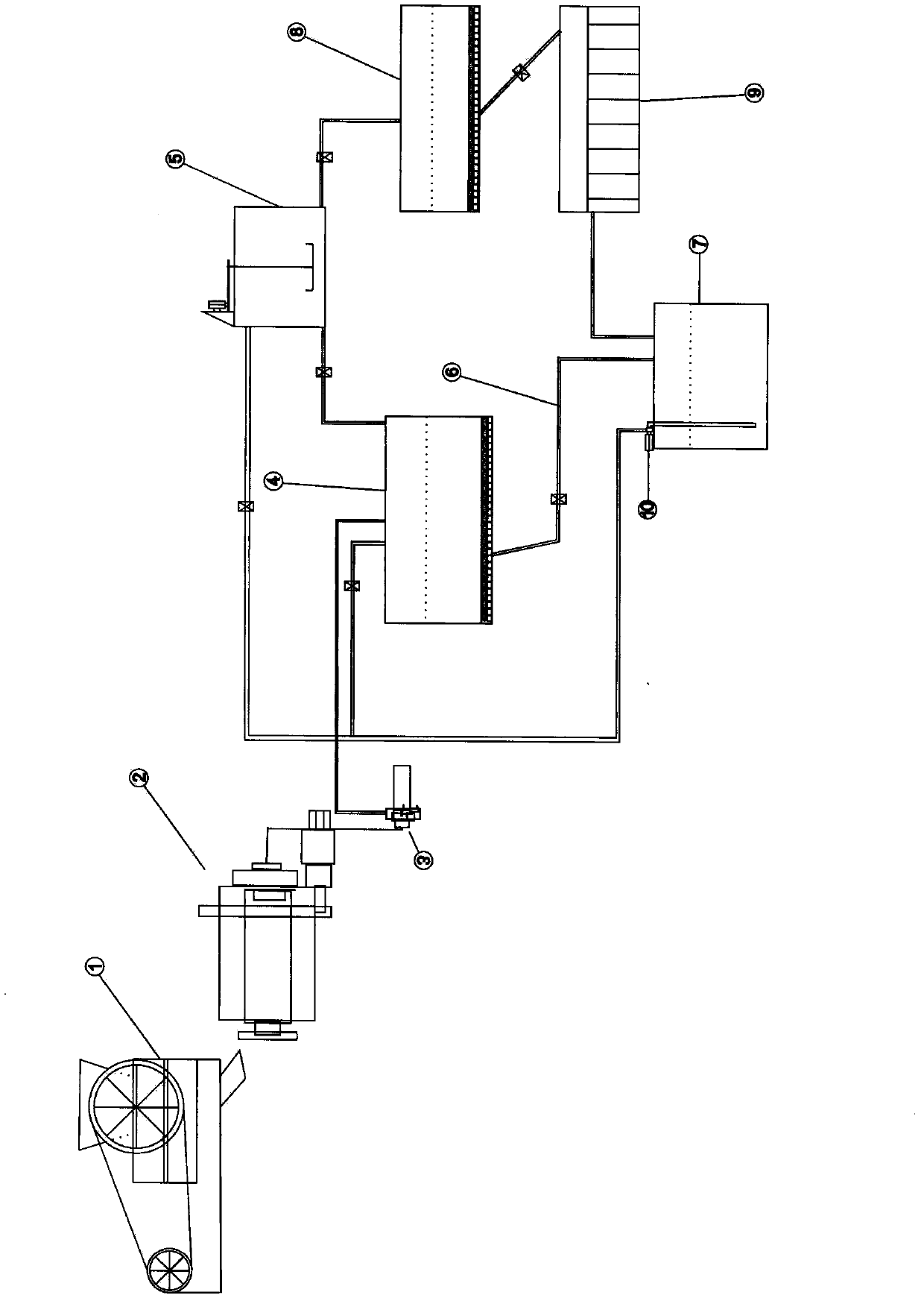

Image

Examples

Embodiment Construction

[0022] A specific embodiment of the present invention is to use a jaw crusher to crush a low-grade copper oxide ore containing 2.7 grams / ton of gold, 52 grams / ton of silver, and 1.2% copper, and the particle size of the crushed ore is below 50mm. The crushed ore is then ground into mineral powder with a particle size of 0.05-0.10mm by the ore grinding equipment, and transported to the leaching tank. Then the mixed solution of ammoniacal liquor, ammonium bicarbonate and sodium thiosulfate (the solubility of ammonia water is 2%, the solubility of ammonium bicarbonate is 3%, sodium thiosulfate 5%) prepared in the mixing tank is used as ore leaching agent, The leaching liquid is input into the leaching tank, and the leaching liquid reacts with the ore powder, the liquid-solid volume ratio is 2:1, and the reaction temperature is 60°C. The resulting copper, gold and silver complex solution permeates to the bottom of the leaching tank by its own weight, flows out from the drain pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com