Cable blocking material and preparation method thereof

A technology for plugging materials and cables, used in rubber insulators, organic insulators, etc., can solve the problems of fire blocking material strength, poor toughness, easy to produce cracks and other problems, achieve excellent anti-aging performance, enhance mechanical strength, and be conducive to material properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

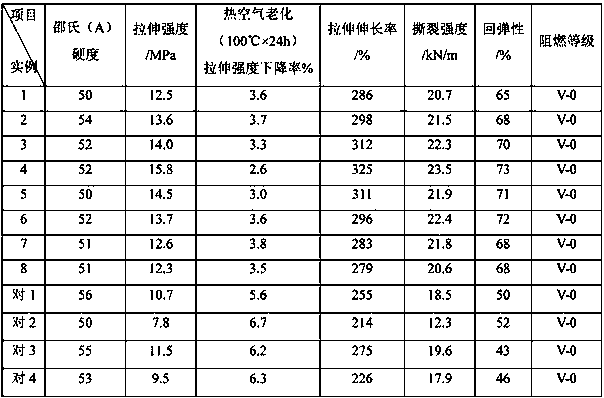

Examples

Embodiment 1

[0021] A cable plugging material, made of the following parts by weight:

[0022] 30 parts of methyl vinyl silicone rubber, 0.5 parts of light calcium carbonate, 3 parts of white carbon black VN-3, 3 parts of mullite fiber, 0.6 parts of hydroxy silicone oil, 1 part of naphthenic oil, 10 parts of aluminum hydroxide, 0.2 part of potassium sulfide, 1 part of di-dipenta vulcanizing agent and 0.5 part of triallyl isocyanurate.

[0023] The vulcanizing agent is 2,5-dimethyl-2,5-di(tert-butylperoxy) hexane, that is, di-dipenta vulcanizing agent.

[0024] The method for preparing the cable plugging material includes the following steps:

[0025] (1) Mix methyl vinyl silicone rubber, light calcium carbonate, white carbon black VN-3, mullite fiber, hydroxy silicone oil, naphthenic oil and aluminum hydroxide at 30°C for 5 minutes, and then add 60 Stir a portion of the toluene solution for 20 minutes, and finally put it into an ultrasonic reactor, ultrasonic treatment for 10 minutes, the ultraso...

Embodiment 2

[0028] A cable plugging material, made of the following parts by weight:

[0029] 32 parts of methyl vinyl silicone rubber, 0.6 parts of light calcium carbonate, 3.5 parts of white carbon black VN-3, 4 parts of alumina fiber, 0.8 parts of hydroxy silicone oil, 1.2 parts of naphthenic oil, 11 parts of aluminum hydroxide, overvulcanization 0.25 parts of potassium, 1.1 parts of di-dipenta vulcanizing agent and 0.6 parts of triallyl isocyanurate.

[0030] The method for preparing the cable plugging material includes the following steps:

[0031] (1) Mix methyl vinyl silicone rubber, light calcium carbonate, white carbon black VN-3, alumina fiber, hydroxy silicone oil, naphthenic oil and aluminum hydroxide at 32°C for 6 minutes, and then add 50 parts The toluene solution was stirred for 25 minutes, and finally put into an ultrasonic reactor, ultrasonic treatment was performed for 6 minutes, and the ultrasonic power was 500W;

[0032] (2) Add potassium persulfide, bis-pentasulfide vulcaniz...

Embodiment 3

[0034] A cable plugging material, made of the following parts by weight:

[0035] 35 parts of methyl vinyl silicone rubber, 0.6 parts of light calcium carbonate, 4 parts of white carbon black VN-3, 4.3 parts of mullite fiber, 1.0 part of hydroxy silicone oil, 1.5 parts of naphthenic oil, 12 parts of aluminum hydroxide, 0.3 parts of potassium sulfide, 1.3 parts of di-dipenta vulcanizing agent and 0.6 parts of triallyl isocyanurate.

[0036] The method for preparing the cable plugging material includes the following steps:

[0037] (1) Mix methyl vinyl silicone rubber, light calcium carbonate, white carbon black VN-3, mullite fiber, hydroxy silicone oil, naphthenic oil and aluminum hydroxide at 35°C for 10 minutes, and then add 70 Part of the toluene solution was stirred for 30 minutes, and finally put into the ultrasonic reactor, ultrasonic treatment for 15 minutes, the ultrasonic power was 600W;

[0038] (2) Add potassium persulfide, bis-dipenta vulcanizing agent and triallyl isocyan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com