Degradable plastic

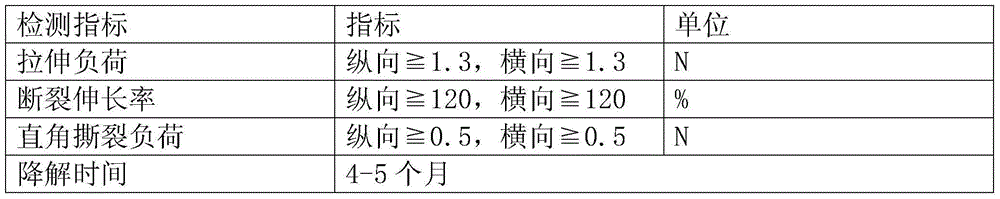

A technology for degrading plastics and plasticizers, applied in the field of plastic raw materials, can solve the problems of poor air permeability, not widely used, and high production costs, and achieve the effects of improving tensile strength, shortening degradation time, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A degradable plastic, the mass parts of the degradable plastic are composed as follows: 40 parts of corn starch microspheres, 12 parts of polyamide, 5 parts of polyhydroxybutyrate, 2 parts of glass fiber, 0.8 parts of zinc stearate, plant 1.2 parts of fiber, 0.8 parts of dispersant, 6 parts of photosensitizer, 8 parts of plasticizer, and 0.8 part of coupling agent.

[0022] Wherein, the plant fiber is selected from coconut fiber, and the length of the coconut fiber is 4.5 μm.

[0023] Wherein, the dispersant is selected from polysodium methacrylate.

[0024] Wherein, the photosensitizer is benzophenone.

[0025] Wherein, the plasticizer is tributyl acetate.

[0026] Wherein, the coupling agent is a silane coupling agent, specifically, the model is KH550.

Embodiment 2

[0028] A degradable plastic, the mass parts of the degradable plastic are composed as follows: 50 parts of cornstarch microspheres, 15 parts of polyamide, 7.5 parts of polyhydroxybutyrate, 7 parts of glass fiber, 1.6 parts of zinc stearate, plant 2.4 parts of fiber, 2.8 parts of dispersant, 8 parts of photosensitizer, 12 parts of plasticizer, and 1.8 parts of coupling agent.

[0029] Wherein, the plant fiber is selected from coconut fiber and corn stalk fiber; the length of the two kinds is 4.5 μm.

[0030] Wherein, the dispersant is selected from sodium polymethacrylate and ammonium polymethacrylate.

[0031] Wherein, the photosensitizer is selected from benzoin dimethyl ether.

[0032] Wherein, the plasticizer is selected from tributyl acetate and dibutyl phthalate.

[0033] Wherein, the coupling agent is a silane coupling agent, specifically, the models are KH550 and DL602.

Embodiment 3

[0035] A degradable plastic, the mass parts of the degradable plastic are composed as follows: 45 parts of cornstarch microspheres, 15 parts of polyamide, 8 parts of polyhydroxybutyrate, 6 parts of glass fiber, 1.6 parts of zinc stearate, plant 3.2 parts of fiber, 3.2 parts of dispersant, 8 parts of photosensitizer, 12 parts of plasticizer, and 1.6 parts of coupling agent.

[0036] Wherein, the plant fiber is selected from coconut fiber, corn stalk fiber and rice straw fiber; the length of the fiber is 5 μm.

[0037] Wherein, the dispersant is selected from sodium polymethacrylate, ammonium polymethacrylate and polyphosphate.

[0038] Wherein, the plasticizer is a mixture of tributyl acetate, dibutyl phthalate and diethyl phthalate.

[0039] Wherein, the coupling agent is a silane coupling agent, specifically, the models are KH550 and DL602.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com