Foamy carbon/paraffin type phase-change composite material and encapsulation method thereof

A technology of phase change composite materials and encapsulation methods, which is applied in the field of foamed carbon/paraffin phase change composite materials and their encapsulation to achieve the effects of improving heat transfer performance, controlling thermal expansion, and reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

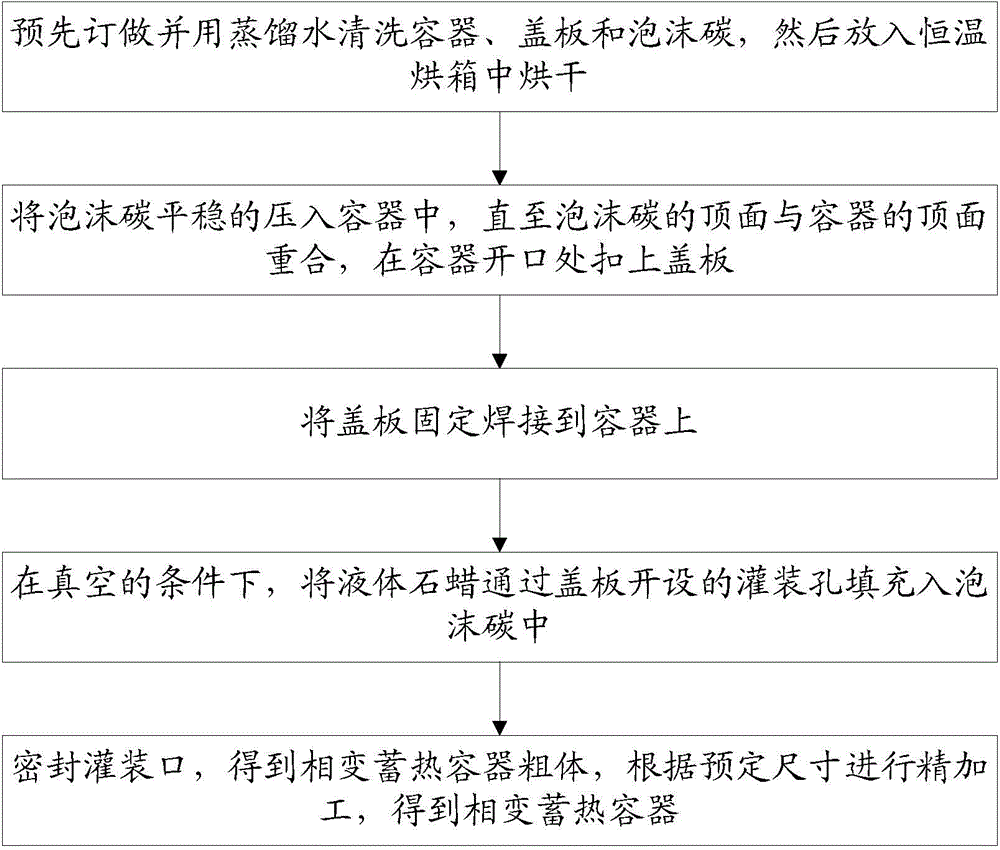

[0027] refer to figure 1 , the carbon foam / paraffin phase change composite material described in this embodiment, the phase change composite material includes: carbon foam 1 and paraffin wax 1 filled in the pores of the carbon foam 1, the quality of the carbon foam 1 is 67g, The mass of the paraffin wax 1 is 95g; the mass fraction of n-octadecane in the paraffin wax is greater than 98%.

[0028] The physical and chemical parameters of the carbon foam 1 are: density 0.43g cm -3 , porosity 81%, thermal conductivity 133W·m -1 ·K -1 , the physical and chemical parameters of the paraffin 1 n-octadecane are: melting point 28.3°C, latent heat 245kJ / kg, thermal conductivity 0.15W·m -1 ·K -1 , density 814 S g cm -3 ,775 L g cm -3 .

[0029] The filling ratio of the paraffin wax 1 in the pores of the carbon foam 1 was 97.3%. It can effectively control the thermal expansion after packaging and reduce the thermal stress of the container.

[0030] The method for encapsulating ...

Embodiment 2

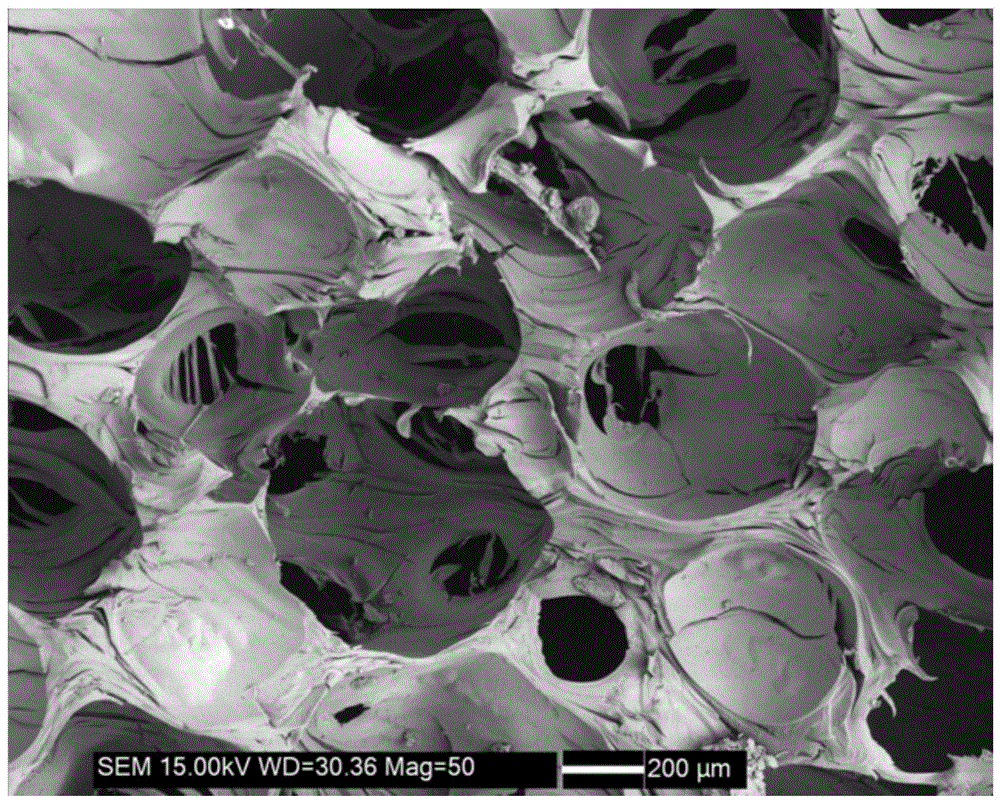

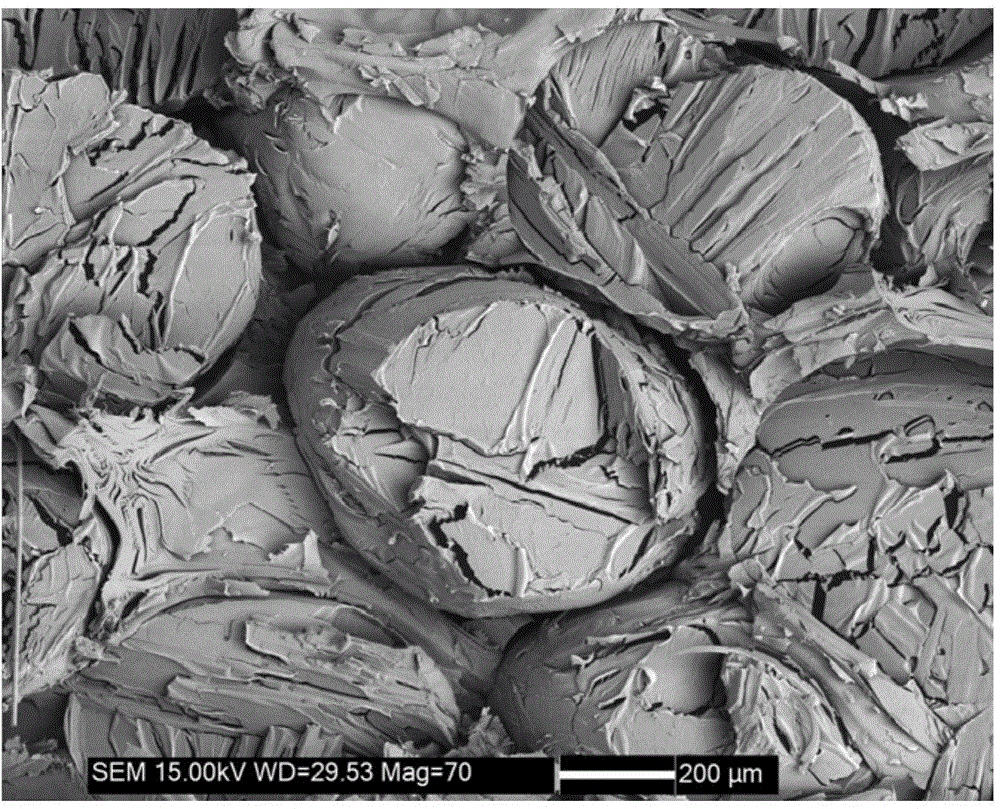

[0038] Example 2, the difference between this example and Example 1 is that the mass fraction of n-eicosane in the paraffin wax is greater than 98%; the quality of paraffin wax 2 is 99g, and the quality of carbon foam 2 is 57g. The physical and chemical parameters of foam carbon 2 are: density 0.37g cm -3 , porosity 84%, thermal conductivity 110W·m -1 ·K -1 , the physical and chemical parameters of the paraffin 1 n-eicosane are: melting point 37°C, latent heat 247kJ / kg, thermal conductivity 0.15W·m -1 ·K -1 , density 856 S -778 L g.cm -3 , others are identical with embodiment 1. The scanning electron micrograph of the carbon foam used in the present embodiment, as figure 2 Shown; The scanning electron micrograph of carbon foam / paraffin phase change composite material described in the present embodiment, as image 3 shown.

[0039] As those skilled in the art know: the high thermal conductivity foamed carbon material is a new type of material that can maintain its ow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| latent heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com