Urea hydrolysis ammonia-production equipment and method

A technology of urea hydrolysis and equipment, which is applied in the field of denitrification raw material gas preparation equipment and preparation, to achieve the effect of easy transformation and timely flow response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

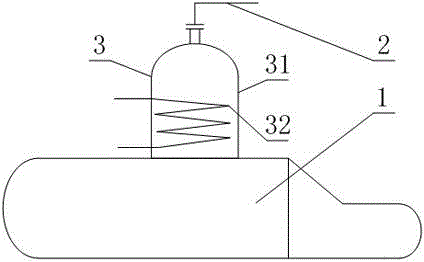

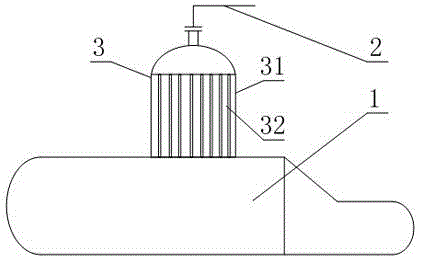

[0027] Such as Figure 1 to Figure 4 As shown, a kind of urea hydrolysis ammonia production equipment comprises ammonia reactor body 1 and gas outlet pipeline 2 connected on the gas outlet of ammonia reactor body 1, there is also a series connection between the ammonia reactor body and outlet pipeline 2 The anti-coagulation buffer 3, the anti-coagulation buffer 3 includes a container body 31 provided with an air inlet and an air outlet, and a heating device 32 arranged on the container body 31, the air inlet and the ammonia reactor body 1 The air outlet of the air outlet is connected, and the inlet end of the air outlet pipeline 2 is connected to the air outlet of the container body 31 .

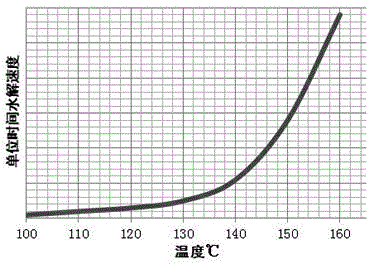

[0028] According to its reaction kinetics, the hydrolysis of urea to ammonia belongs to the first-order reaction, such as image 3 As shown, the reaction kinetic parameters are mainly a function of temperature. Conventional urea hydrolysis reactors are all designed with constant pressure a...

Embodiment 2

[0031] Such as figure 1 , figure 2 and Figure 4 , this embodiment is further limited on the basis of embodiment 1: as figure 1 , as a form of heating equipment 32 with relatively uniform temperature distribution on the heating surface and low operating cost of the heat source, the heating equipment 32 is a heat exchange coil arranged inside the container body 31 . Based on the internal pressure or exhaust pressure of the existing ammonia reactor body 1, combined with the actual temperature at which the components in the ammonia-containing product gas recondense to form solids or crystals under this pressure condition, the thermal fluid of the heat exchange coil should be steam . As the implementation of this solution in this embodiment, due to the structure of anti-coagulation buffer 3, the internal pressure of ammonia reactor body 1 may rise in some cases, such as the gas output of ammonia-containing products is greater than that of denitrification When the system is co...

Embodiment 3

[0036] This embodiment provides a method for using the above equipment to realize ammonia production by urea hydrolysis. This method is similar to the structural design of any one of the above-mentioned embodiments, and can achieve the same technical effect. The above-mentioned structure is based on this method. Urea is hydrolyzed to produce ammonia. The method is to heat urea aqueous solution to obtain ammonia-containing product gas containing ammonia components, and temporarily store and heat the ammonia-containing product gas in the subsequent transmission process of ammonia-containing product gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com