Antimicrobial deodorizing plastic for refrigerators and preparation method thereof

A technology of refrigerators and plastics, applied in the field of nanomaterials, can solve the problems of unpleasant odors in refrigerators, and achieve the effects of keeping food healthy, requiring low equipment, and simple and easy preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

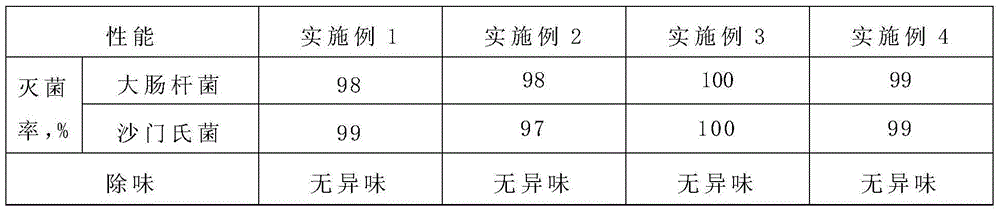

Examples

Embodiment 1

[0017] An antibacterial and deodorizing plastic for refrigerators, comprising the following raw materials in parts by mass: 60 parts of polyethylene, 2 parts of nano silicon dioxide, 0.5 parts of flame retardant, 10100.1 parts of antioxidant, and 1 part of toughening agent , 1 part of dispersant, 5 parts of nano silver.

[0018] A method for preparing antibacterial and deodorizing plastics for refrigerators in this embodiment comprises the following steps: adding polyethylene, nano silicon dioxide, and nano silver to a high-speed mixer according to the proportion, and stirring at a speed of 400 r / min for 10 min Make it mix evenly, then add the rest of the materials and continue to stir for 5 minutes. The mixed materials are extruded and granulated by twin-screw. , to obtain the antibacterial and deodorizing plastics for refrigerators.

Embodiment 2

[0020] An antibacterial and deodorizing plastic for refrigerators, comprising the following raw materials in parts by mass: 65 parts of polypropylene, 4 parts of nano silicon dioxide, 2 parts of flame retardant, 1681 parts of antioxidant, and 5 parts of toughening agent , 1.5 parts of dispersant, 10 parts of nano silver.

[0021] A method for preparing antibacterial and deodorizing plastics for refrigerators in this embodiment comprises the following steps: adding polypropylene, nano silicon dioxide, and nano silver to a high-speed mixer according to the proportion, and stirring at a speed of 400 r / min for 10 min Make it mix evenly, then add the rest of the materials and continue to stir for 5 minutes. The mixed materials are extruded and granulated by twin-screw. , to obtain the antibacterial and deodorizing plastics for refrigerators.

Embodiment 3

[0023] An antibacterial and deodorizing plastic for refrigerators, comprising the following raw materials in parts by mass: 72 parts of polyethylene, 6 parts of nano silicon dioxide, 1 part of flame retardant, 16800.5 parts of antioxidant, and 8 parts of toughening agent , 1.6 parts of dispersant, 12 parts of nano silver.

[0024] A method for preparing antibacterial and deodorizing plastics for refrigerators in this embodiment comprises the following steps: adding polyethylene, nano silicon dioxide, and nano silver to a high-speed mixer according to the proportion, and stirring at a speed of 400 r / min for 10 min Make it mix evenly, then add the rest of the materials and continue to stir for 5 minutes. The mixed materials are extruded and granulated by twin-screw. , to obtain the antibacterial and deodorizing plastics for refrigerators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com