Preparation method of novel PET packing belt masterbatch

A packing belt and masterbatch technology, applied in the field of packaging materials, can solve the problems of poor aging resistance and easy aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

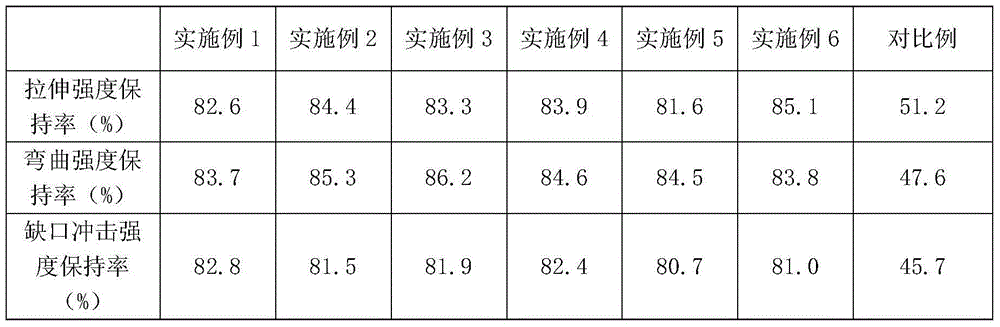

Examples

Embodiment 1

[0025] A preparation method for a novel PET strap masterbatch, comprising the following steps:

[0026] (1) Wash the fly ash floating beads with water, add a hydrofluoric acid solution with a concentration of 0.5mol / L and stir for 8 minutes, the weight ratio of the fly ash floating beads to the hydrofluoric acid solution is 1:25, and suction filter Finally, wash with water for 5 times, place the temperature in an oven at 140°C and dry for 3 hours to obtain acidified fly ash floating beads;

[0027] (2) adding the acidified fly ash bleaching beads that step (1) obtains into the aqueous solution of 5% cetyltrimethylammonium chloride, the acidifying fly ash bleaching beads and cetyl trimethylammonium The weight ratio of the aqueous ammonium chloride solution is 1:36. After ultrasonic stirring for 2 hours, let it stand for 2 hours. The acidified fly ash floating beads suspended in the upper layer and the acidified fly ash floating beads precipitated at the bottom are poured into t...

Embodiment 2

[0031] A preparation method for a novel PET strap masterbatch, comprising the following steps:

[0032] (1) Wash the fly ash floating beads with water, add a hydrofluoric acid solution with a concentration of 0.5mol / L and stir for 8 minutes, the weight ratio of the fly ash floating beads to the hydrofluoric acid solution is 1:25, and suction filter Finally, wash with water for 5 times, place the temperature in an oven at 140°C and dry for 3 hours to obtain acidified fly ash floating beads;

[0033] (2) adding the acidified fly ash bleaching beads that step (1) obtains into the aqueous solution of 5% cetyltrimethylammonium chloride, the acidifying fly ash bleaching beads and cetyl trimethylammonium The weight ratio of the aqueous ammonium chloride solution is 1:36. After ultrasonic stirring for 2 hours, let it stand for 2 hours. The acidified fly ash floating beads suspended in the upper layer and the acidified fly ash floating beads precipitated at the bottom are poured into t...

Embodiment 3

[0037] A preparation method for a novel PET strap masterbatch, comprising the following steps:

[0038] (1) Wash the fly ash floating beads with water, add a hydrofluoric acid solution with a concentration of 0.5mol / L and stir for 8 minutes, the weight ratio of the fly ash floating beads to the hydrofluoric acid solution is 1:25, and suction filter Finally, wash with water for 5 times, place the temperature in an oven at 140°C and dry for 3 hours to obtain acidified fly ash floating beads;

[0039] (2) adding the acidified fly ash bleaching beads that step (1) obtains into the aqueous solution of 5% cetyltrimethylammonium chloride, the acidifying fly ash bleaching beads and cetyl trimethylammonium The weight ratio of the aqueous ammonium chloride solution is 1:36. After ultrasonic stirring for 2 hours, let it stand for 2 hours. The acidified fly ash floating beads suspended in the upper layer and the acidified fly ash floating beads precipitated at the bottom are poured into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com