Paper element micro-fluidic chip proteolysis reactor and preparation method thereof

A microfluidic chip and proteolysis technology are applied in the field of a paper core microfluidic chip proteolysis reactor and its preparation, which can solve the problems of easy loss and affect the effect of enzymolysis, and achieve low cost, cost reduction and simple equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

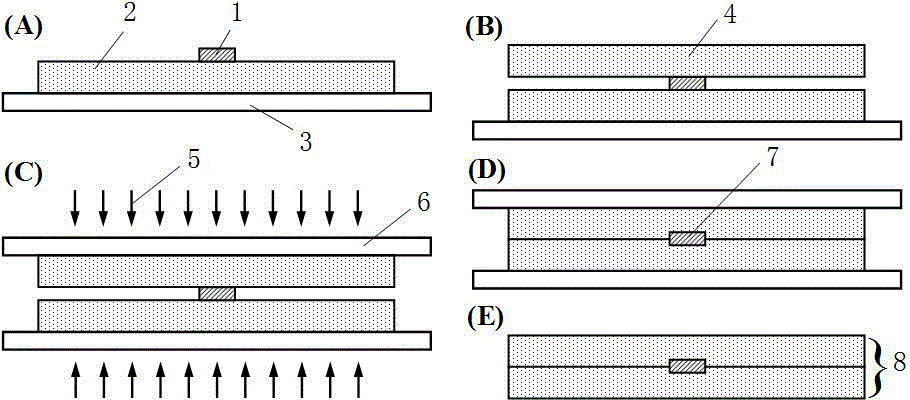

[0042] Further describe the present invention below by embodiment and accompanying drawing:

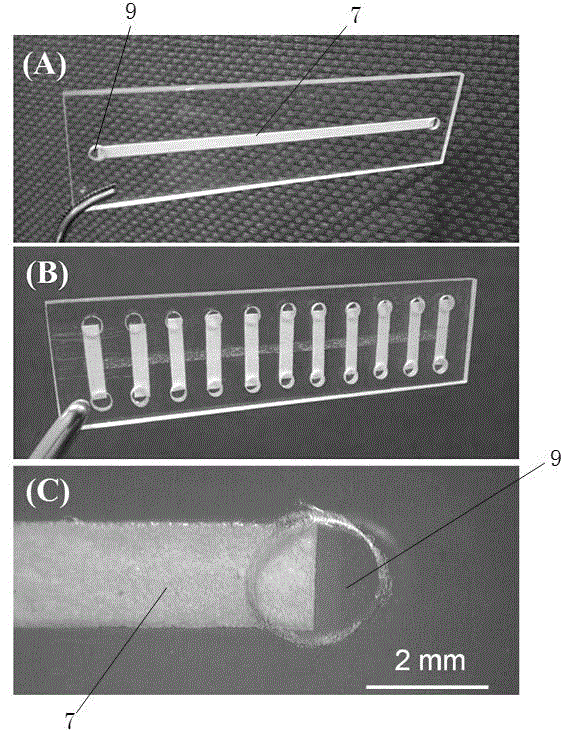

[0043] 1. Single-channel paper core microfluidic chip proteolysis reactor and its preparation method

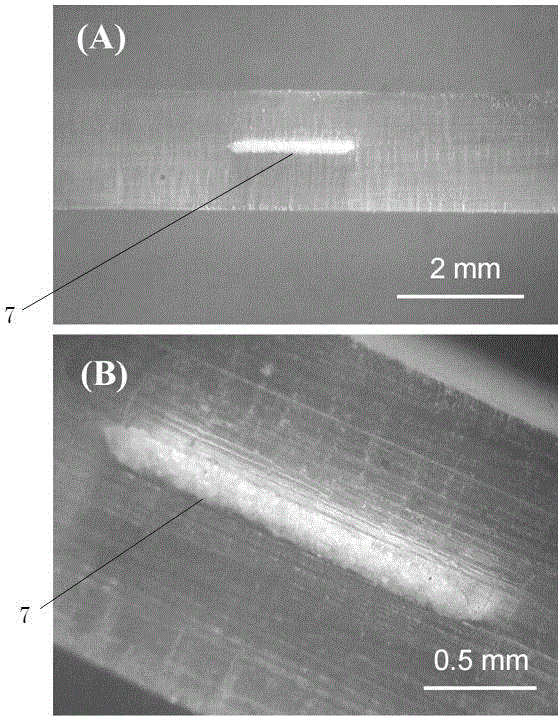

[0044] Cut the plexiglass plate with a thickness of 1 mm into small pieces 2 or 4 of the chip size (60 mm×16 mm×1 mm) to be prepared. Cut qualitative filter paper with a thickness of 200 μm into paper strips 1 with a length of 54 mm and a width of 2 mm by a blade. Such as figure 1 As shown, after wetting with water, paste it on the plexiglass sheet 2 cut into the size of the chip. After drying, cover another plexiglass sheet 4 of the same size with a solution connection hole with a diameter of 2 mm, and clamp it on the glass sheet. 3 and 6 (76.2 mm × 25 mm × 1.2 mm), and then use a spring-driven pressure device to apply an external pressure 5, the pressure is 6 kg / cm2. Then, the device was placed in a blast oven at a temperature of 130°C and heated for 10 minutes. The paper core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com