Preparation method of superconducting wire rod

A superconducting wire and superconducting layer technology, applied in the manufacture/processing of superconductor devices, etc., can solve problems affecting the superconducting performance of superconducting wires, increase contact resistance, etc., and achieve the effect of uniform thickness and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The invention provides a method for preparing a superconducting wire, comprising:

[0015] The step of forming an intermediate layer on the substrate; the step of forming a superconducting layer on the intermediate layer; the step of forming a silver stabilizing layer on the superconducting layer; immersing the silver stabilizing layer into an aqueous copper sulfate solution after forming the silver stabilizing layer and passing The copper plating treatment step of electroplating to form a copper stable layer on the silver stable layer is characterized in that the copper sulfate aqueous solution contains copper sulfate pentahydrate, sulfuric acid, chloride ions, nonionic surfactants and anionic surfactants. .

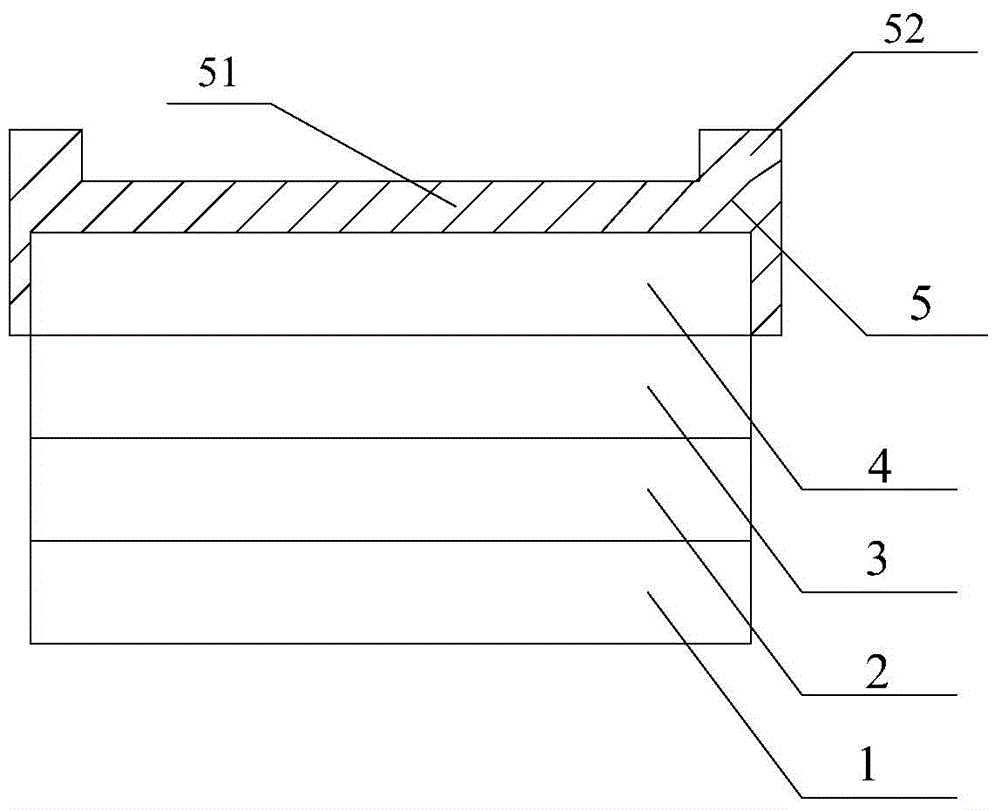

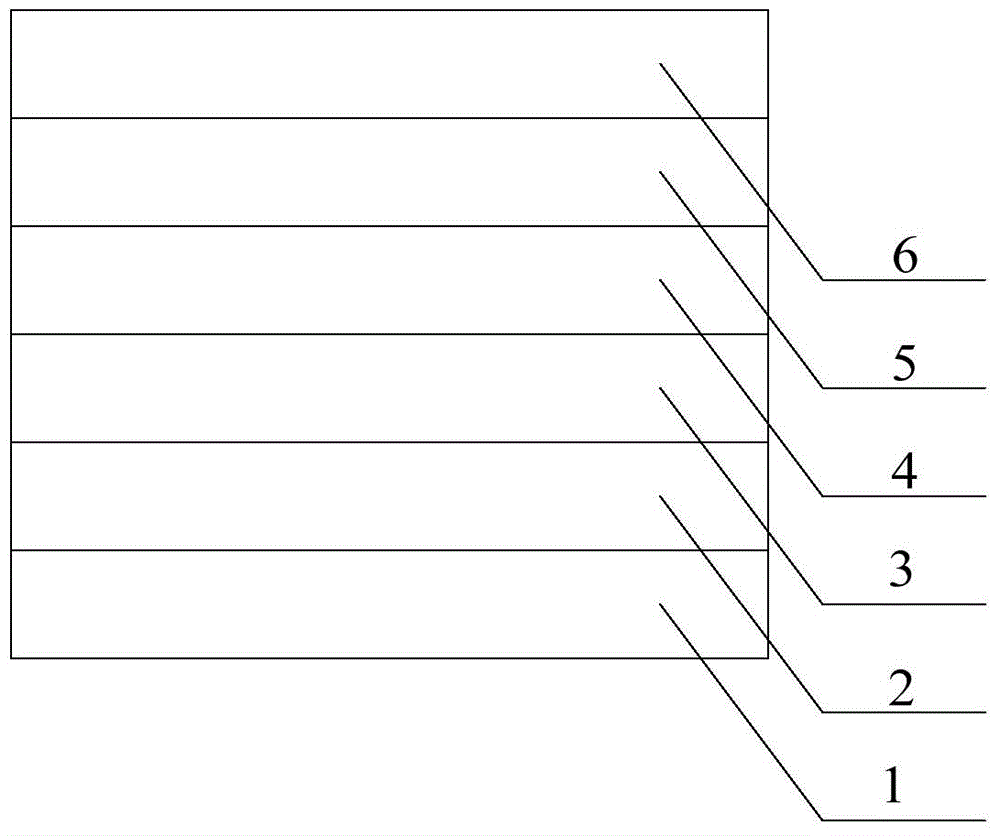

[0016] see figure 2 , figure 2 Schematic diagram of the structure of the superconducting wire provided by the embodiment of the present invention, wherein 1 is the substrate, 2 is the intermediate layer formed on the substrate 1, 3 is the superconducting laye...

Embodiment 1

[0036] On a Ni alloy substrate (Hastelloy (registered trademark) strip) sequentially use the sputtering method to form Al 2 o 3 layer, sputtering method to form Y 2 o 3 layer, IBAD method to form MgO layer, sputtering method to form LaMnO 3 layer and sputtering method to form CeO 2 layer; in CeO 2 A YBaCuO superconducting layer is formed on the layer by a MOD method; an Ag layer is formed by a sputtering method to form a superconducting wire with an Ag layer structure.

[0037] The wire is immersed in 20°C, 5mL / L sulfuric acid solution for 10s, and then washed with water for 10s; the washed superconducting wire is used as a cathode for electroplating in an aqueous copper sulfate solution to form a 15 μm thick Cu layer on the Ag layer, The copper sulfate aqueous solution includes 200g / L copper sulfate pentahydrate, 80g / L sulfuric acid, 300ppm potassium chloride, 0.3g / L polyethylene glycol and 0.05g / L sodium lauryl sulfate, the copper sulfate aqueous solution The temperatu...

Embodiment 2

[0041] The superconducting wire was prepared by the same method as in Example 1, except that the superconducting wire formed with the Ag layer was immersed in a 5 mL / L hydrochloric acid solution at 20° C. for 10 s, and then washed with water for 10 s.

[0042] After the surface is copper-plated, the peel strength and Ic value of the superconducting wire are measured, and the results are shown in Table 1. Table 1 is the test results of the peel strength and Ic value of the superconducting wire provided by the embodiment of the present invention;

[0043] After the copper plating on the surface, the film thickness of the central part and the film thickness of the edge part of the Cu layer of the superconducting wire were measured, and the results are shown in Table 2. Table 2 shows the film thickness of the Cu layer on the surface of the superconducting wire provided by the embodiment of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com