Combined fireproof cable tray for power supply system cable and installation method of combined fireproof cable tray

A technology of a power supply system and an installation method, which is applied to electrical components and other directions, can solve the problems of increasing the unexpected frequency of the power supply system, troublesome secondary installation of bridges, poor fire resistance and fire resistance, etc., so as to save materials and resources, shorten working time, and prolong use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

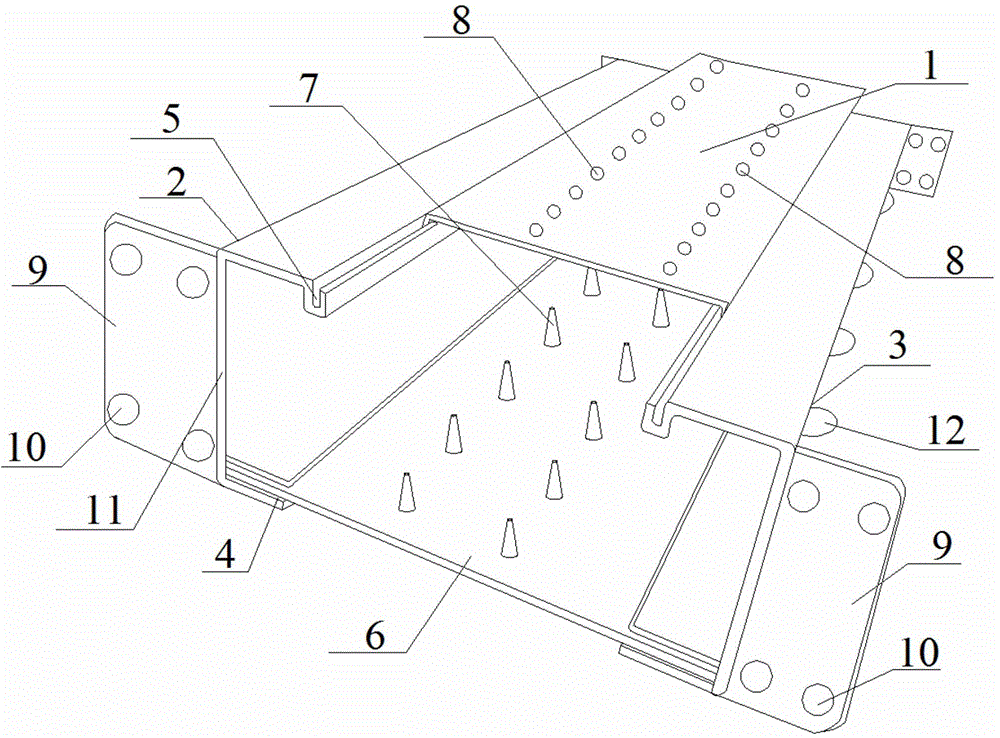

[0034] This embodiment provides a combined fireproof bridge for power supply system cables, the structure of which is as follows: figure 1 As shown, it includes the trough frame and the protective cover 1 arranged on the trough frame. The trough frame is coated with a fire-proof and heat-insulating layer. The fire-proof and heat-insulating layer is a fiber composite heat-insulating board. Connected to the channel frame, the channel frame is composed of the left side wall beam 2, the right side wall beam 3 and the bottom plate 6 arranged between the left and right side wall beams, wherein:

[0035] The shield 1 includes a shield plate and buckles extending from both ends of the shield plate, the buckles are perpendicular to the shield plate, two rows of round holes 8 are arranged along the length direction of the shield plate, and each row has at least 10 round holes 8 ;

[0036] The left side wall beam 2 has the same structure as the right side wall beam 3. The left side wall...

Embodiment 2

[0039] This embodiment provides an installation method for a combined fireproof bridge for power supply system cables in the above-mentioned embodiment 1. The installation method specifically includes the following steps:

[0040] (1) Preparation for installation: Carry out technical clarification according to the approved construction plan, calculate the actual demand for the bridge frame according to the construction plan, check and accept the bridge frame and its accessories on site, and the specifications and quantities should meet the requirements of the construction plan;

[0041](2) Bridge positioning and marking: According to the construction drawing and design plan, find out the relative elevation of the horizontal, vertical, turning and the ground and the relative distance between the wall along the direction of the bridge, pop up the corresponding lines or lines, and draw them evenly and equidistantly The position of the column, the bending radius of the bridge turni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com