Plasma series compensation gap system

A plasma and plasma generator technology, which is applied in the field of ion series compensation gap system, can solve the problems of uneven partial pressure of two arcing gaps, self-triggering voltage lower than design value, complex spark gap structure, etc., so as to improve electromagnetic reactance. Interference, elimination of component failure rate, effect of simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

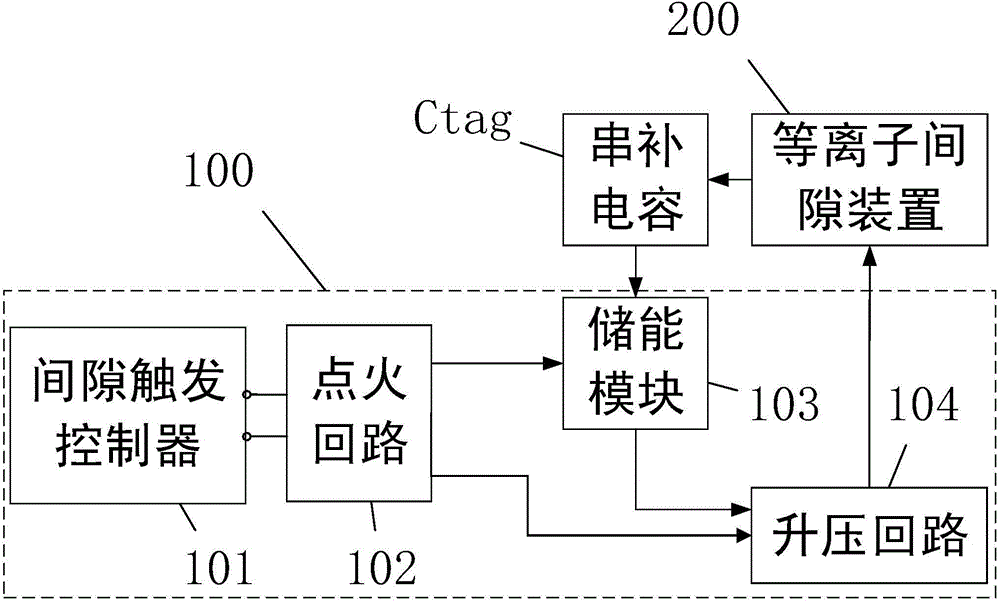

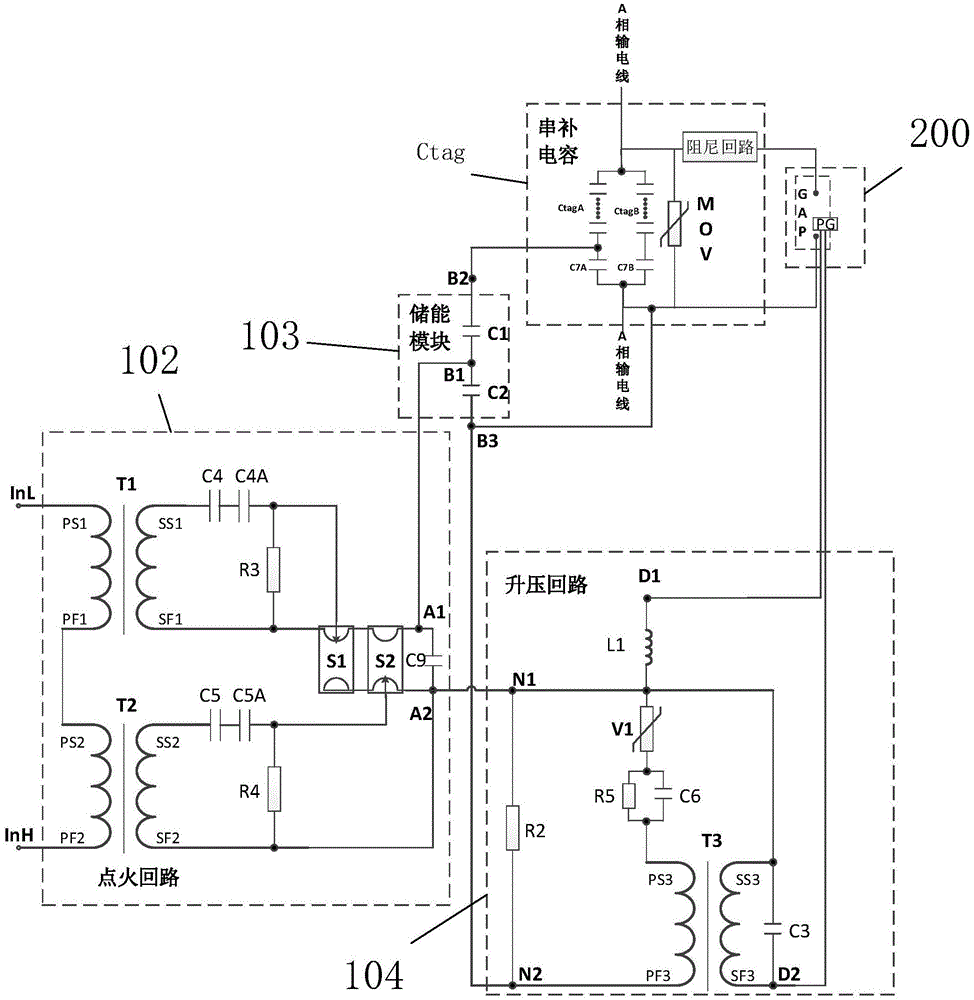

[0023] see figure 1 , is a connection block diagram of Embodiment 1 of a plasma series compensation gap system of the present invention. The plasma series compensation gap system of this embodiment is used to protect the series compensation capacitor Ctag connected in series on the three-phase line of the high-voltage transmission line, that is, every The phase line configuration has a series compensation capacitor Ctag. The series compensation capacitor Ctag includes one or two parallel capacitor banks in series. In this embodiment, two sets of capacitor banks in series are preferably used to connect a set of plasma series compensation gap systems, and the second plasma gap system is used as a backup system. The two sets of series capacitor banks are the first series capacitor bank CtagA and the second series capacitor bank CtagB, and the series compensation capacitor Ctag also includes a metal oxide voltage limiter MOV connected in parallel at both ends of the above series c...

Embodiment 2

[0052] see Figure 4 , is the connection block diagram of Embodiment 2 of the dual-ignition plasma series compensation gap system of the present invention.

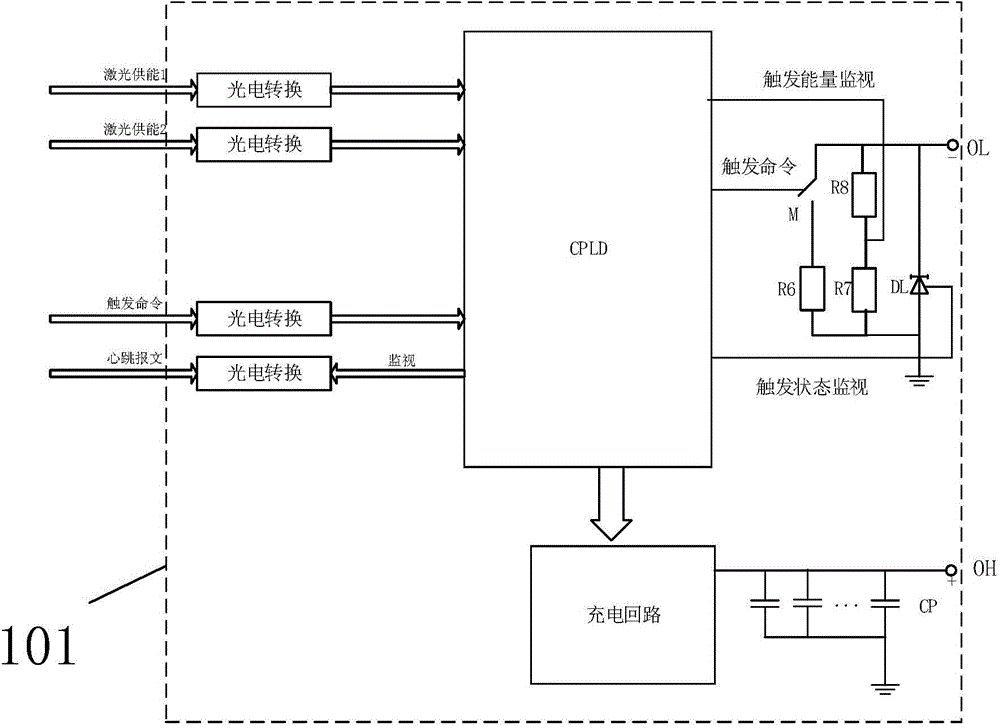

[0053]Embodiment 2 of the present invention, on the basis of the gap trigger device 100 and the plasma gap device 200 of the above-mentioned embodiment 1, also includes a laser power supply device 300 and a series compensation protection device 400, and the laser power supply device 300 is used for Provide laser energy to the gap trigger controller 101. In this embodiment, two energy supply optical fibers are used as energy supply lines, and the two optical fibers are used as backups for each other to improve system reliability. As another embodiment, only One energy supply optical fiber, or two or more energy supply optical fibers, using laser energy to replace the energy supply mode of cables and inductance coils, can avoid the electromagnetic interference introduced by cables, thereby reducing the probability of damage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com