Greenhouse carbon dioxide generator

A carbon dioxide and generator technology, applied in greenhouse cultivation, agricultural machinery and equipment, horticulture, etc., can solve the problems of increasing the decomposition pressure of thermal decomposition reactants, increasing the decomposition temperature, and consuming heat, so as to achieve complete and sufficient absorption of ammonia gas and reduce energy consumption. Consumption and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

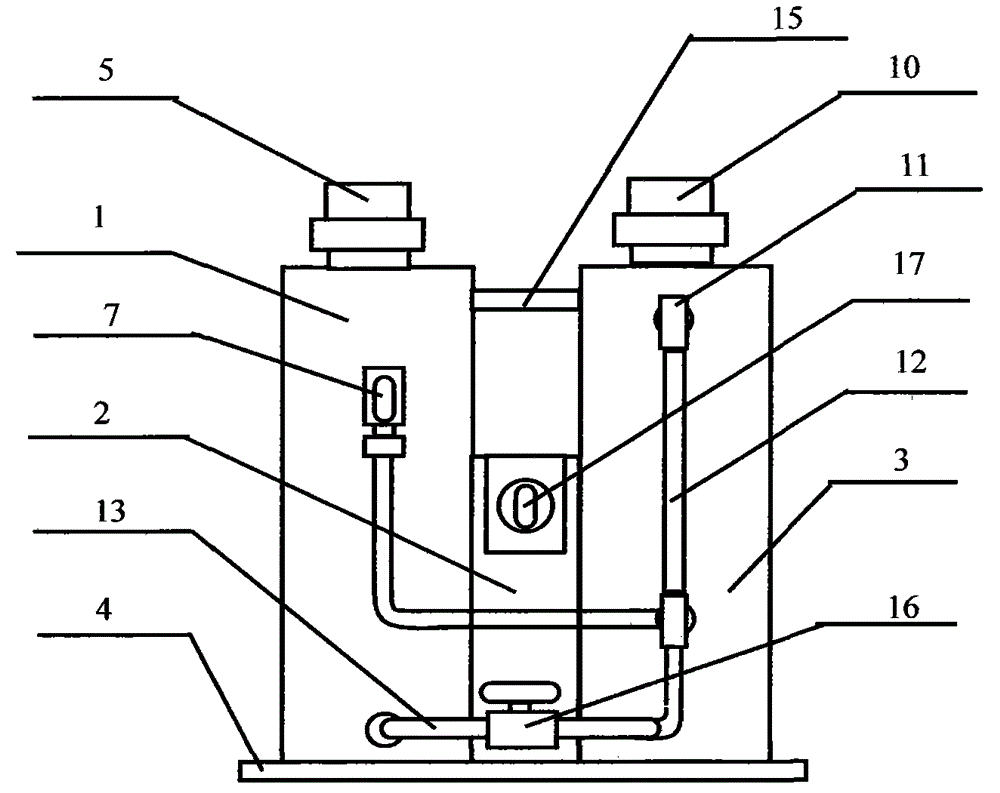

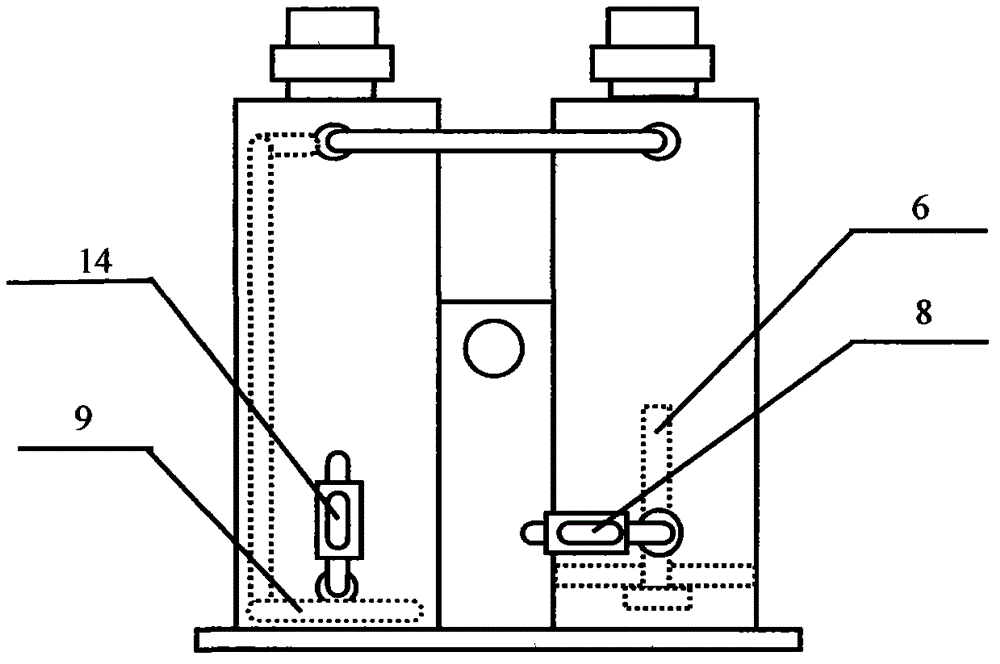

[0032] Example 1: see figure 1 , figure 2, this embodiment includes a thermal decomposition reactor 1, the side wall of the thermal decomposition reactor 1 is fixedly connected to the side wall of the ammonia gas absorber 3 through a fixed connection plate 2, and the bottom ends are fixedly connected to the bottom support plate 4, The top of the thermal decomposition reactor 1 is provided with a feeding sealing cover 5, the bottom is provided with a heater 6, the side wall is provided with an overflow valve 7 and a waste discharge valve 8, and the inside of the ammonia absorber 3 is provided with a microporous filter. 9, the top is provided with a water inlet sealing cover 10, and the side wall is provided with a carbon dioxide exhaust port 11, a liquid level pipe 12, a connecting pipe 13, an ammonia discharge valve 14 and a mixed gas pipe 15, and the mixed gas pipe 15 and the thermal decomposition reactor 1 connected, the microporous filter 9 is connected with the gas mixtu...

Embodiment 2

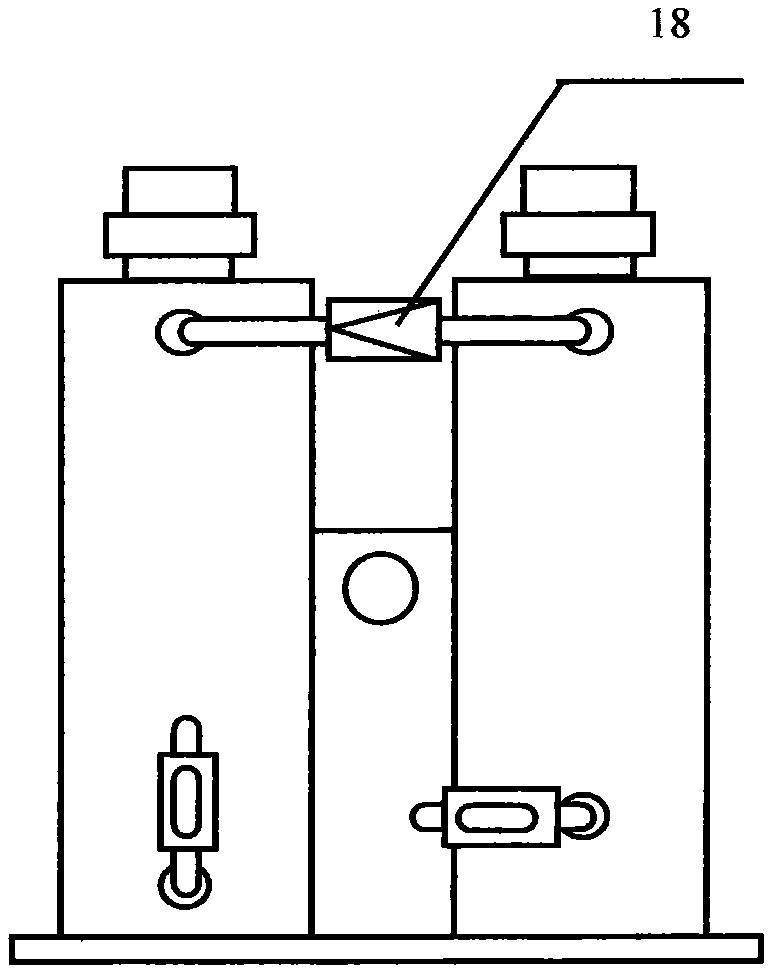

[0033] Example 2: see image 3 , present embodiment is provided with check valve 18 on gas mixture pipe 15, and other structures are the same as embodiment 1. This embodiment is applicable to the use of intermittent and multiple replenishment of carbon dioxide for each feeding in a single greenhouse. It can replenish carbon dioxide multiple times in different periods of time by feeding once a day; Daily carbon dioxide supplementation.

Embodiment 3

[0034] Embodiment 3: see Figure 4 , present embodiment is provided with radiator 19 on gas mixture pipe 15, and other structures are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com