Method for manufacturing medicine balloons

A technology of balloons and drugs, applied in catheters, coatings, etc., to achieve high drug content, maintain mechanical properties, and increase the effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Preparation of drug solution: Add 0.15 g of paclitaxel and 0.3 g of PVP into 10 mL of ethanol, mix well, and heat at 40° C. until paclitaxel and PVP are completely dissolved.

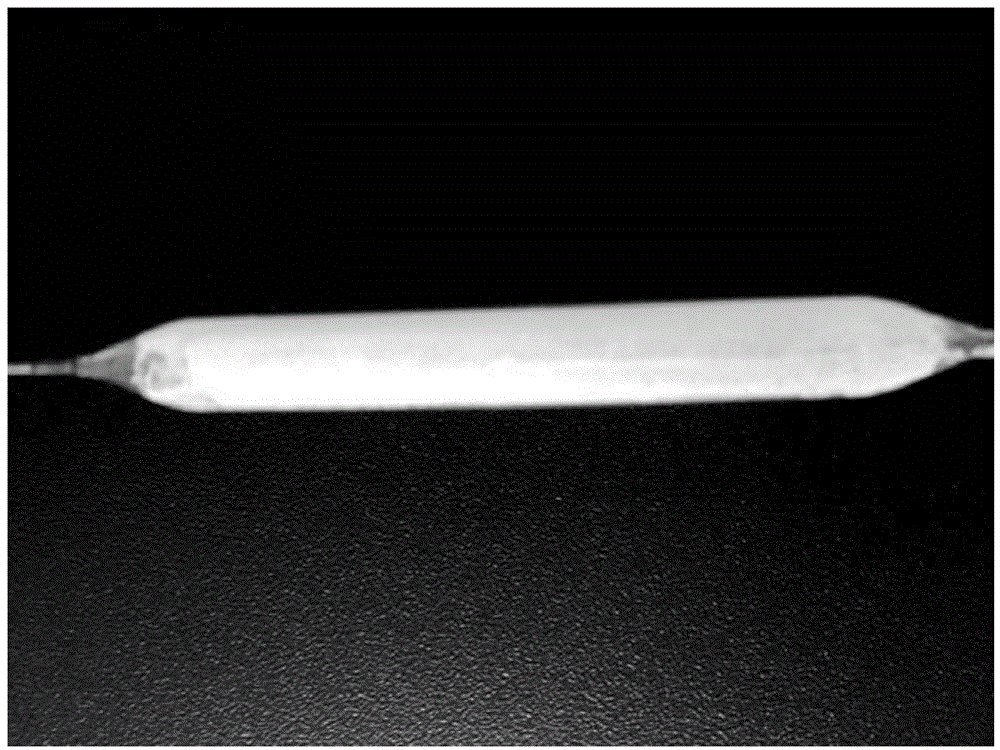

[0042] (2) Particle coating preparation: take a balloon with a size of 4.0mm*60mm, and use an ultrasonic spraying process to spray a sodium chloride solution with a concentration of 0.5 mg / mL on the surface of the balloon, and obtain a 1 μm thick particle coating after drying.

[0043] (3) Balloon drug coating: the balloon with particle coating is immersed in the drug solution in step (1), and the temperature of the drug solution is lowered to -20° C., and kept for 1 hour.

[0044] (4) The balloon was slowly taken out, and the balloon was left to dry at 40° C. for 30 minutes to obtain a drug balloon with a drug coating thickness of 10 μm.

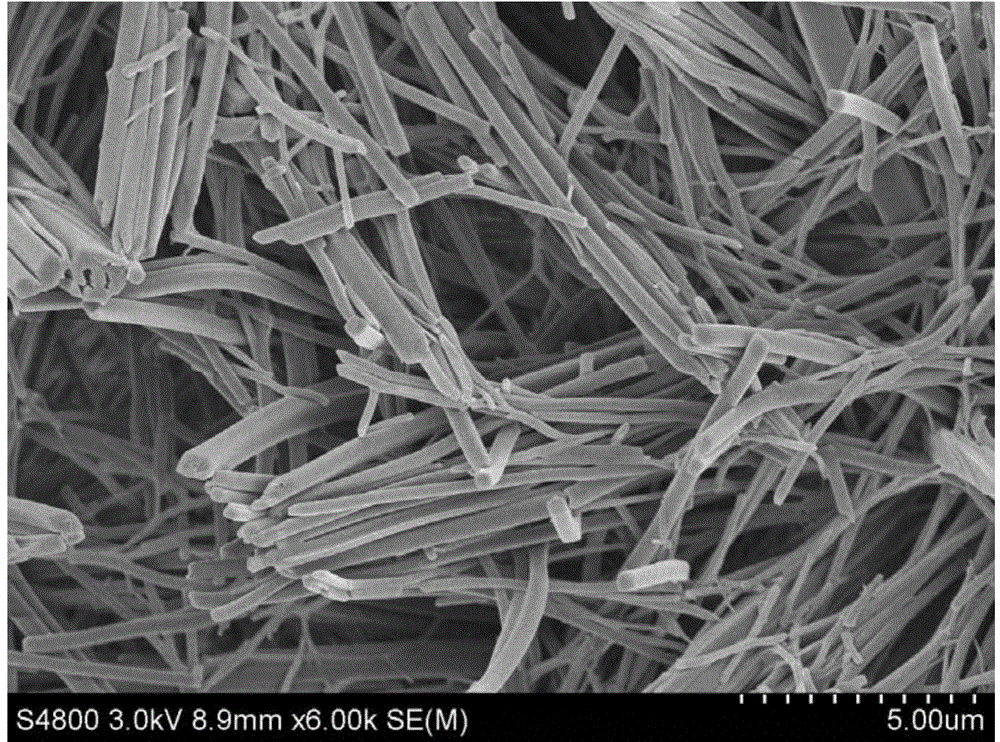

[0045] figure 1 It is the SEM picture of the surface of the drug balloon prepared in Example 1. It can be seen from the picture that the surface of the d...

Embodiment 2

[0047] (1) Preparation of drug solution: Add 0.5 g of paclitaxel and 0.3 g of PEG into 10 mL of methanol, mix well, and heat at 60° C. until paclitaxel and PEG are completely dissolved.

[0048](2) Balloon particle coating preparation: take a balloon with a size of 3.0mm*20mm, use ultrasonic spraying process, spray calcium chloride solution with a concentration of 10mg / mL on the surface of the balloon, and obtain a 5μm thick particle coating after drying .

[0049] (3) Add 1ml of water for injection to the solution in step (1), stir well and let stand for 1 minute.

[0050] (4) Submerge the microparticle-coated balloon in the solution of step (3), and keep at room temperature for 1 hour.

[0051] (5) The above-mentioned balloon was slowly taken out, and the balloon was left to dry at room temperature for 1 hour to obtain a drug-coated balloon with a drug-coating thickness of 20 μm.

Embodiment 3

[0053] (1) Preparation of drug solution: 0.13 g of rapamycin and 0.3 g of PVA were added into 10 ml of acetonitrile, stirred to completely dissolve the drug.

[0054] (2) Balloon particle coating preparation: immerse a 4.0mm*30mm balloon in 20mg / mL urea solution, take out the balloon slowly after 10 minutes, place it at 40°C, and obtain a 30μm thick particle coating after drying ;

[0055] (3) Balloon drug coating: the balloon with microparticle coating is immersed in the drug solution in step (1), and the temperature of the drug solution is lowered to -60° C. and kept for 30 minutes.

[0056] (4) The balloon was slowly taken out, and the balloon was left to dry at room temperature for 30 minutes to obtain a drug balloon with a drug coating thickness of 15 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com