Purifying method and set of high-temperature oil-bearing waste gas for heat-setting machine

A heat-setting machine and purification device technology, applied in chemical instruments and methods, combined devices, separation methods, etc., can solve the problems of large waste of heat energy, prone to explosion, catalyst poisoning, etc., achieve high purification efficiency and avoid pipeline blockage , the effect of simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

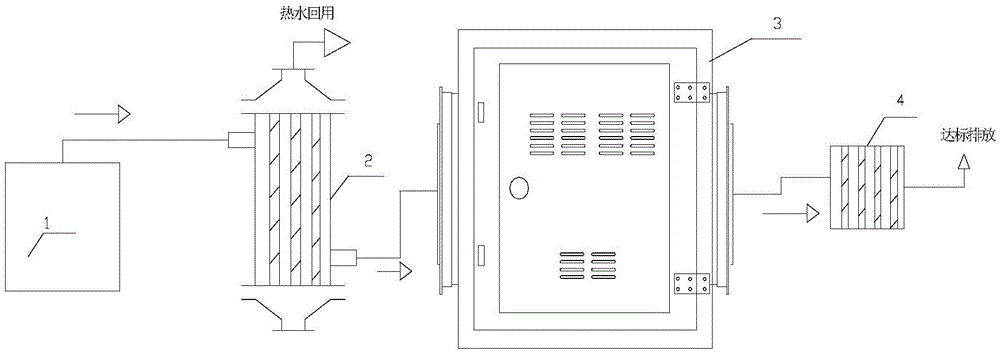

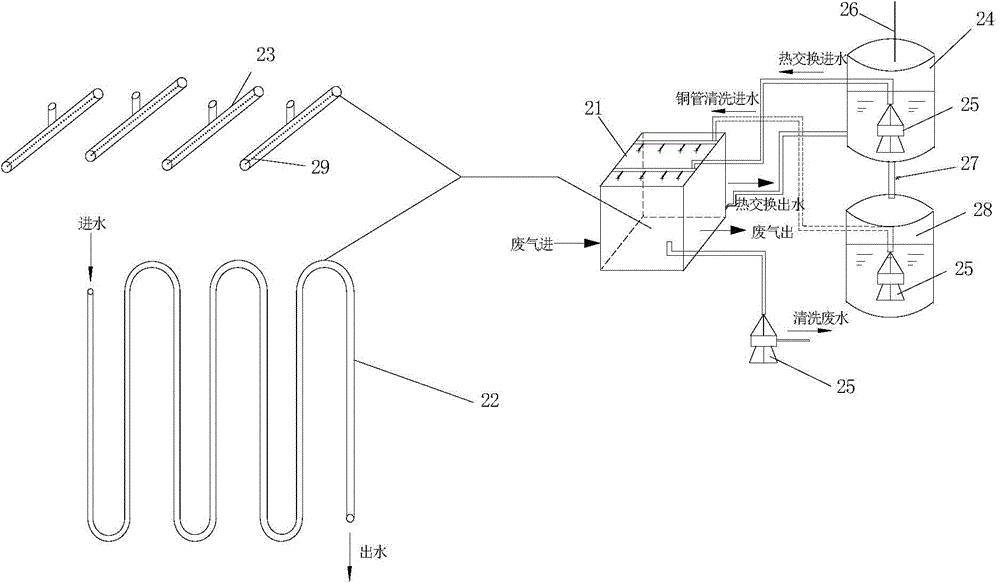

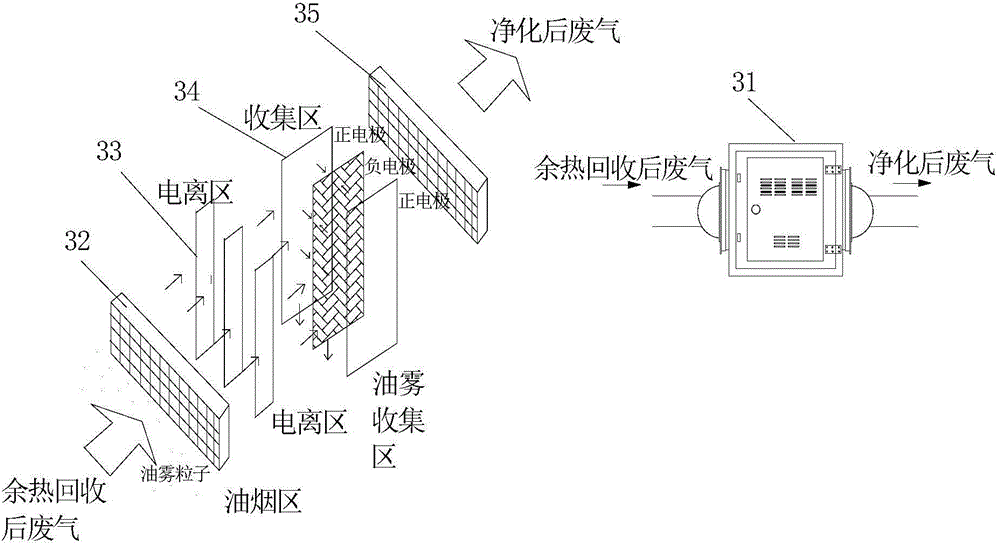

[0041] The invention provides a method and device for purifying high-temperature oil-containing waste gas of a heat-setting machine. The simulated oily fume waste gas device 1 generates high-temperature oil-containing waste gas from a simulated heat-setting machine at a temperature of 150-170°C. The high-temperature oil-containing waste gas of the simulated heat setting machine passes through the gas-water heat pipe high-efficiency heat exchange device 2 to reduce the temperature of the waste gas to below 60 degrees, recover the heat energy in the waste gas and condense some components in the waste gas; then enter the new deoiling process Dust removal equipment 3 removes large solid particles and condensed liquid oil particles in the exhaust gas; finally, finely filters through the ramie filter 4 equipped with ramie fiber tubes to furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com