A kind of relatively stable propane dehydrogenation propylene catalyst and preparation method thereof

A catalyst and stability technology, applied in the field of propane catalytic dehydrogenation to propylene catalyst and its preparation, can solve the problems of deactivation, easy carbon deposition of the catalyst, etc., and achieve the effects of long service life, easy implementation and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

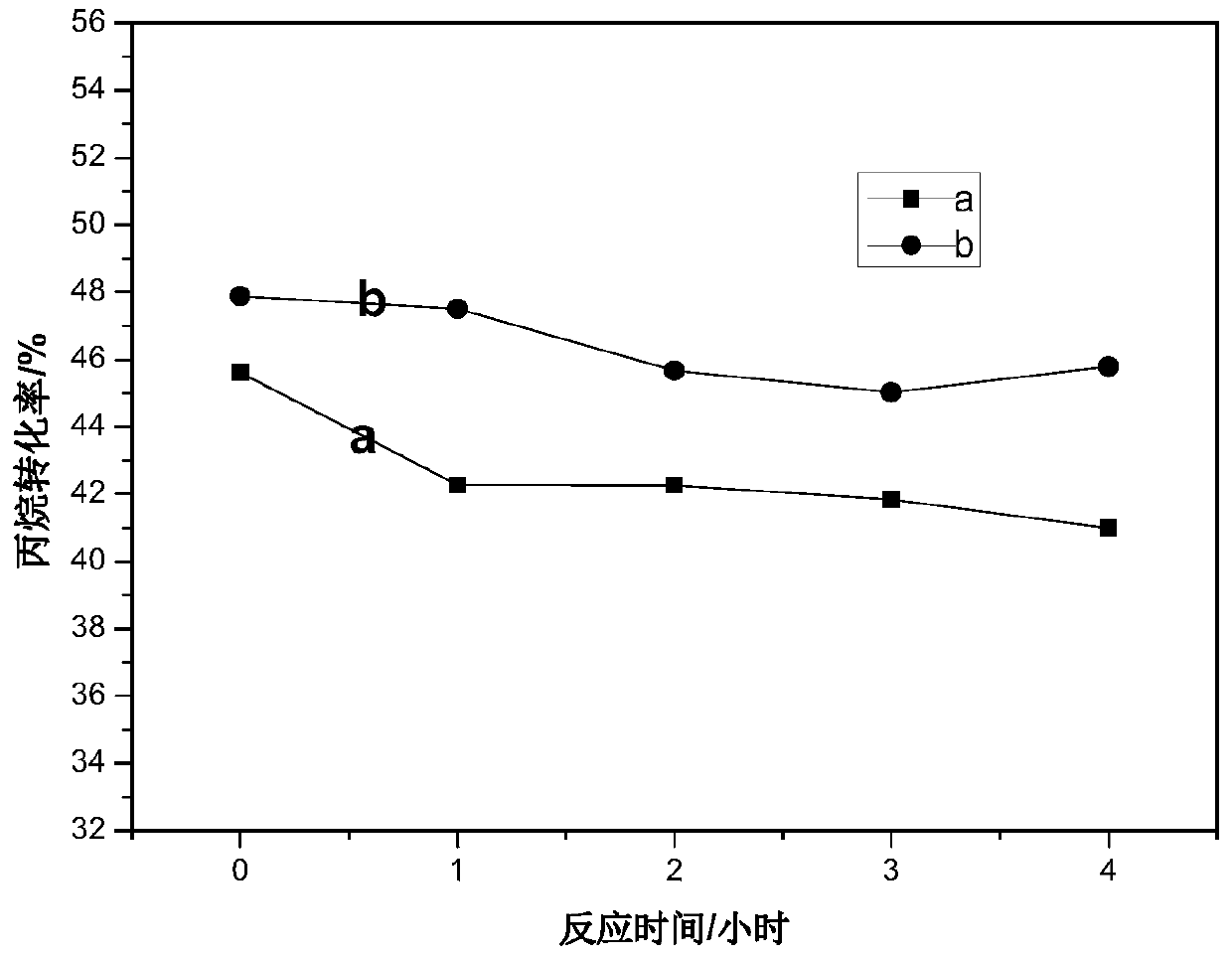

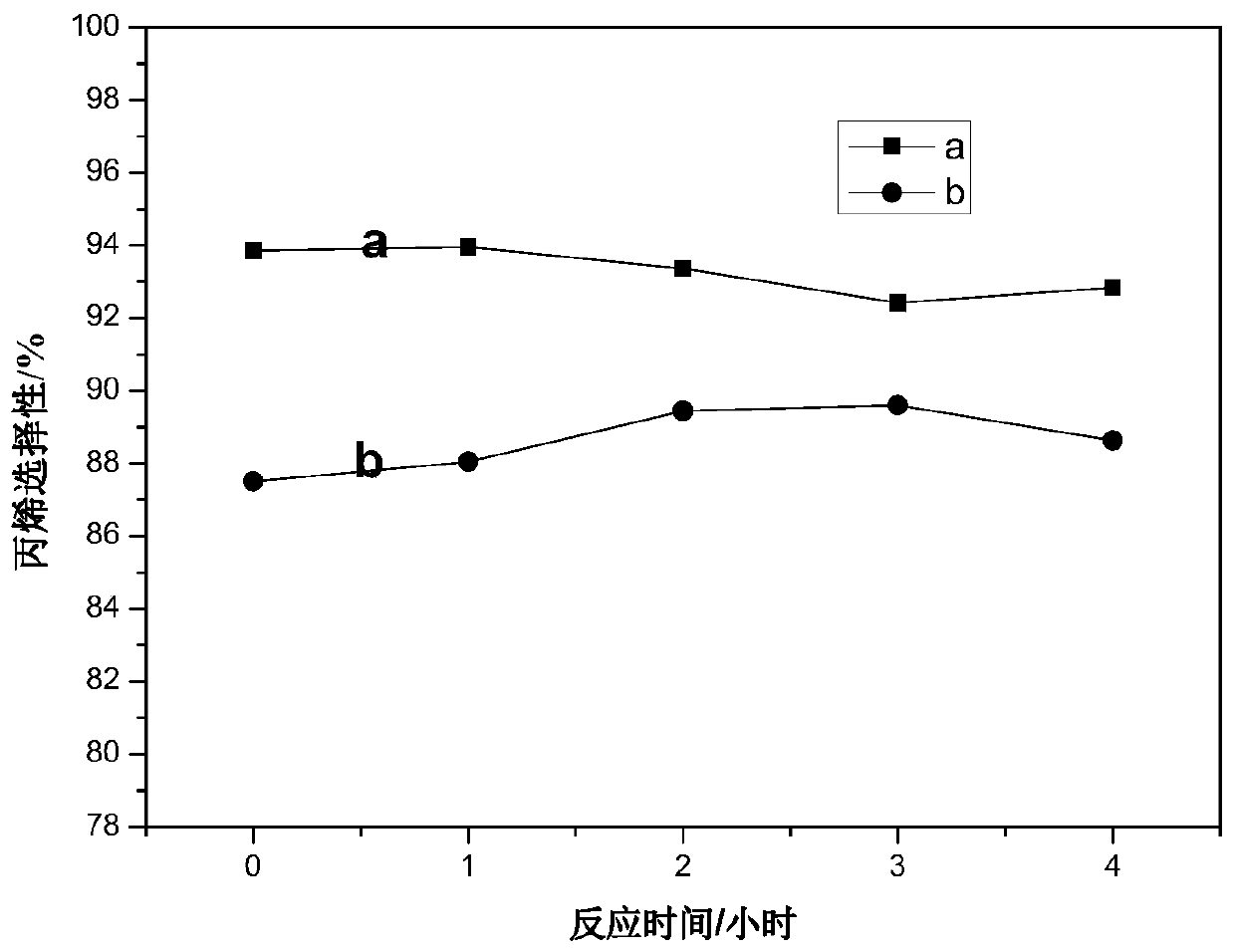

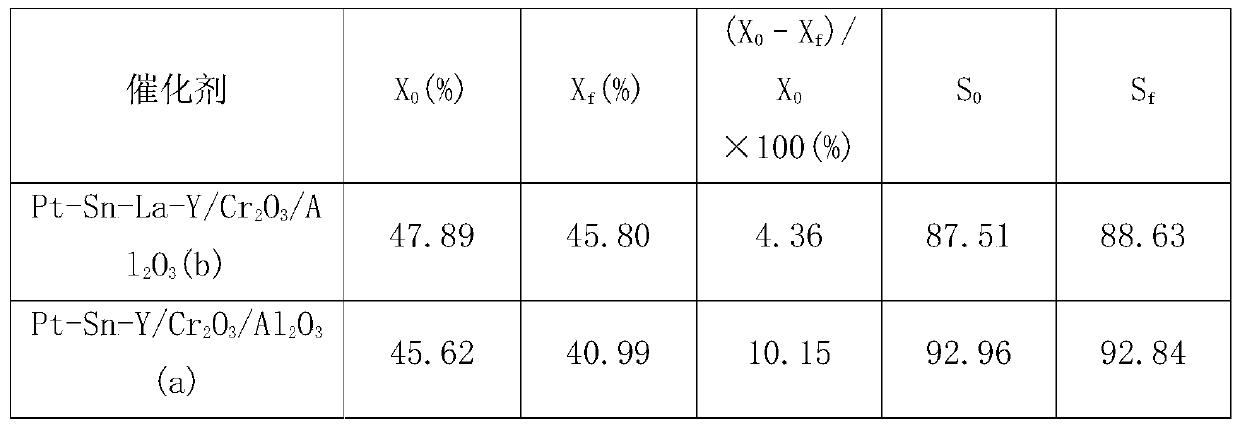

Embodiment 1

[0028]A relatively stable catalyst for the catalytic dehydrogenation of propane to propylene, using the composite oxide alumina-chromium oxide as the composite support, metal Pt as the active component, and metal Sn and Y as additives, through continuous impregnation method Add metal ions Pt, Sn and Y, whose chemical formula is Pt-Sn-Y / Cr 2 o 3 ·Al 2 o 3 , Cr in composite carrier 2 o 3 with Al 2 o 3 The mass ratio of the catalyst is 2:1, and the mass percentage of each component in the catalyst is: Pt 0.4%, Sn 0.6%, Y 1.1%; its preparation method, the steps are as follows:

[0029] 1) Preparation of mixed carrier by co-precipitation method

[0030] 7.8953g Al(NO 3 ) 3 9H 2 O and 5.5188g Cr(NO 3 ) 3 9H 2 O was added to 150mL deionized water, stirred and dissolved, then ultrasonicated for 15min, and while stirring, ammonia water with a concentration of 28wt% was added dropwise to a pH value of 5.1, the precipitate was separated and washed twice with absolute ethanol...

Embodiment 2

[0036] A relatively stable catalyst for the catalytic dehydrogenation of propane to propylene, using the composite oxide alumina-chromia as the composite support, metal Pt as the active component, and metal Sn, La and Y as additives, through continuous Metal ions Pt, Sn and Y are added by impregnation method, and its chemical formula is Pt-Sn-La-Y / Cr 2 o 3 ·Al 2 o 3 , Cr in composite carrier 2 o 3 with Al 2 o 3 The mass ratio of the catalyst is 2:1, and the mass percentage of each component in the catalyst is: Pt0.4%, Sn 0.6%, La 1.1%, Y 0.5%; its preparation method, the steps are as follows:

[0037] 1), 2) are identical with embodiment 1;

[0038] 3)Pt-Sn-La-Y / Cr 2 o 3 ·Al 2 o 3 preparation of

[0039] In the above 1.5g Pt-Sn / Cr 2 o 3 ·Al 2 o 3 In, add 3.35mL La(NO 3 ) 3 ·6H 2 O aqueous solution was stirred for 12 h, dried and calcined at 550 °C for 4 h to obtain Pt-Sn-La / Cr 2 o 3 ·Al 2 o 3 , and then add 0.45mL of Y(NO 3 ) 3 The aqueous solution was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com