Method for milling of catalyst for preparation of acrylic acid by reactive ball mill

A catalyst and acrylic acid technology, applied in chemical instruments and methods, carboxylate preparation, organic compound preparation, etc., can solve the problems of low selectivity, low activity, etc., and achieve the effect of high acrylic acid selectivity and high propane conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

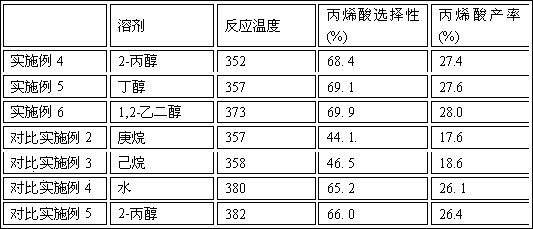

Examples

Embodiment 1

[0031] 1 g of the catalyst prepared in Comparative Example 1 was loaded into a 60 ml container, and 15 zirconia balls with a diameter of 10 mm and 80 zirconia balls with a diameter of 5 mm were added thereto. 15 ml of water was added thereto, followed by ball milling at 150 rpm for 15 hours.

[0032] After ball milling, the catalyst and solvent are recovered. 30 cc of solvent was added thereto, followed by centrifugation at 4000 rpm for 2 hours. To detect whether impurities are leached from the catalyst, recover and observe the centrifuged solution. It was tan in color, indicating that impurities were leached. The catalyst precipitated at the bottom of the bottle was recovered, dried at 80 °C for 4 h, and then ground in agate to obtain the final catalyst.

Embodiment 2

[0034] 1 g of the catalyst prepared in Comparative Example 1 was loaded into a 60 ml container, and 15 zirconia balls with a diameter of 10 mm and 80 zirconia balls with a diameter of 5 mm were added thereto. 15 ml of ethanol was added thereto, followed by ball milling at 150 rpm for 15 hours.

[0035]After ball milling, the catalyst and solvent are recovered. 30 cc of solvent was added thereto, followed by centrifugation at 4000 rpm for 2 hours. To detect whether impurities are leached from the catalyst, recover and observe the centrifuged solution. It was tan in color, indicating that impurities were leached. The catalyst precipitated at the bottom of the bottle was recovered, dried at 80 °C for 4 h, and then ground in agate to obtain the final catalyst.

Embodiment 3

[0037] 1 g of the catalyst prepared in Comparative Example 1 was loaded into a 60 ml container, and 15 zirconia balls with a diameter of 10 mm and 80 zirconia balls with a diameter of 5 mm were added thereto. 15 ml of 1-propanol was added thereto, followed by ball milling at 150 rpm for 15 hours.

[0038] After ball milling, the catalyst and solvent are recovered. 30 cc of solvent was added thereto, followed by centrifugation at 4000 rpm for 2 hours. To detect whether impurities are leached from the catalyst, recover and observe the centrifuged solution. It was tan in color, indicating that impurities were leached. The catalyst precipitated at the bottom of the bottle was recovered, dried at 80 °C for 4 h, and then ground in agate to obtain the final catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com