Preparation method of zn-zsm-5 and its application in propane dehydrogenation to propylene

A propane dehydrogenation, zn-zsm-5 technology, applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., can solve the problems of high production cost, large amount of template agent, low utilization rate of reactor, etc. Achieve the effects of low pollution, low consumption, and obvious social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

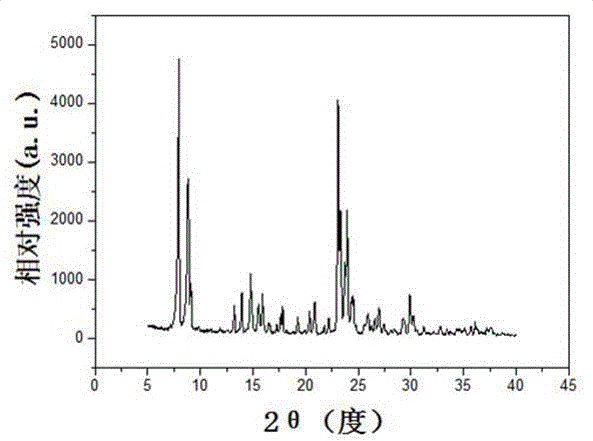

[0037] Zinc nitrate, tetraethyl orthosilicate, water and hydrochloric acid are mixed according to the molar ratio of 0.00368: 1: 20: 0.2, stirred to form a homogeneous solution, then an aerosol is generated by an aerosol generator, and zinc silicon oxide is obtained by drying, Put 1g of zinc silicon oxide into a 1.67ml stainless steel synthesis kettle with polytetrafluoroethylene lining, and then add 1.34g of tetrapropylammonium hydroxide aqueous solution (mass fraction 25%), wherein tetrapropylammonium hydroxide and zinc silicon SiO in oxide 2 The molar ratio is 0.1: 1, sealed at 170°C for crystallization reaction for 72h, the obtained solid product is dried at 100°C and then roasted at 540°C for 6h to remove the template agent, and the final product 0.5wt% Zn-ZSM- 5 Catalyst 0.95g. Equivalent to 1L crystallization kettle can produce 569g Zn-ZSM-5. The XRD pattern of this product is shown in figure 1 , it can be seen that there are five diffraction peaks at 2theta of 7.9°,...

Embodiment 2

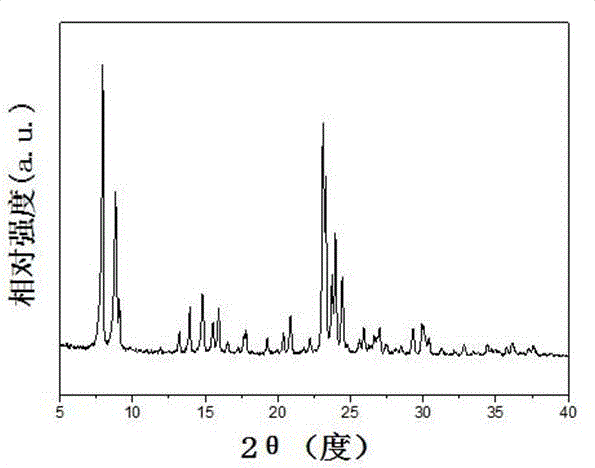

[0039] 1) Mix zinc nitrate, tetraethyl orthosilicate, water and hydrochloric acid according to the molar ratio of 0.02272: 1: 20: 0.2, stir to form a homogeneous solution, then generate an aerosol through an aerosol generator, and dry to obtain zinc-silicon oxide Put 1g of zinc silicon oxide into 1.67ml stainless steel synthetic kettle with polytetrafluoroethylene lining, then add 1.34g of tetrapropylammonium hydroxide aqueous solution (mass fraction 25%), wherein tetrapropylammonium hydroxide and SiO in Zinc Silicon Oxide 2 The molar ratio is 0.1: 1, sealed at 170°C for crystallization reaction for 72h, the resulting solid product is dried at 100°C and then roasted at 540°C for 6h to remove the template agent, and the final product 3wt% Zn-ZSM-5 catalyst. The XRD pattern of this product is shown in figure 2 , it can be seen that there are five diffraction peaks at 2theta of 7.9°, 8.8°, 23°, 23.9°, and 24.4° on the XRD spectrum, which are characteristic diffraction peaks of...

Embodiment 3

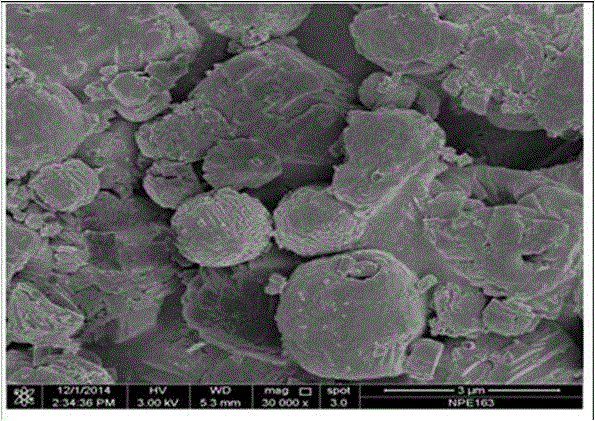

[0043] 1) Mix zinc nitrate, tetraethyl orthosilicate, water and hydrochloric acid according to the molar ratio of 0.03872: 1: 20: 0.2 and stir for 1 hour to form a homogeneous solution, then generate an aerosol through an aerosol generator, and dry to obtain zinc silicon Oxide, 1g of zinc silicon oxide was put into 1.67ml stainless steel synthetic kettle with polytetrafluoroethylene lining, and then added 1.34g of tetrapropylammonium hydroxide (mass fraction 25%), wherein tetrapropylammonium hydroxide and SiO in Zinc Silicon Oxide 2 The molar ratio is 0.1: 1, sealed at 170°C for crystallization reaction for 72h, the resulting solid product is dried at 100°C and then roasted at 540°C for 6h to remove the template agent, and the final product 5wt% Zn-ZSM-5 catalyst. The XRD pattern of this product is shown in Figure 4 , it can be seen that there are five diffraction peaks at 2theta of 7.9°, 8.8°, 23°, 23.9°, and 24.4° on the XRD spectrum, which are characteristic diffraction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com