Method for treating wastewater containing hexavalent chromium

A hexavalent chromium and wastewater technology, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of complicated equipment, large land occupation, and high cost, and achieve low cost, good effect, and reduced dosage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

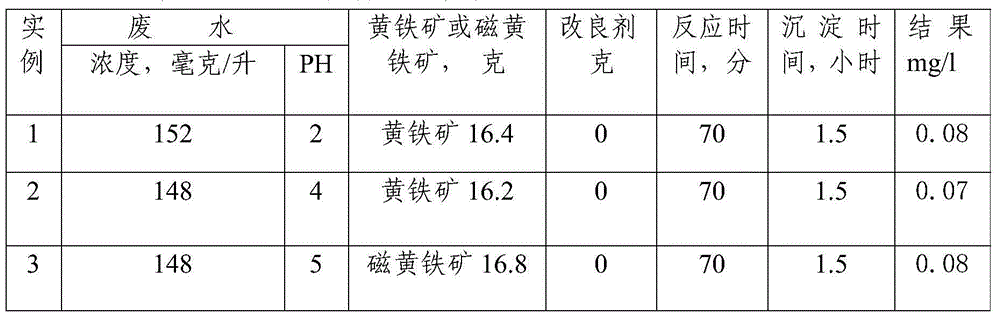

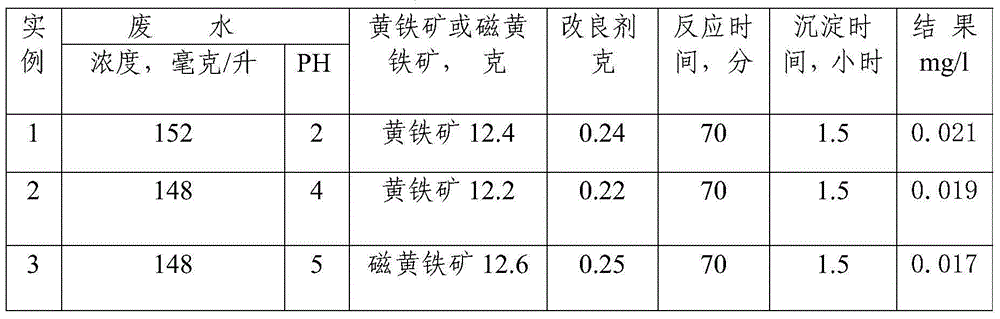

Method used

Image

Examples

Embodiment 1

[0030] Cr content in the electroplating workshop of Beijing Qingyun Aviation Instrument Factory 6+ Wastewater is treated, its Cr 6+ The concentration was 125.5 mg / l. Pyrite ore (commercially available) is pulverized and passed through a 150-mesh sieve to obtain pyrite ore powder; modifier polycarboxylic acid (commercially available) is added to the pyrite ore powder in an amount of pyrite ore 1.5% of the weight of the ore powder, and stirred evenly to obtain the improved pyrite ore powder. Add the improved pyrite ore powder into the waste water containing hexavalent chromium according to the addition amount of 25g / l waste water, the pH value of the waste water containing hexavalent chromium is 2, fully stir, the reaction time is 50 minutes, and the reaction forms Cr 2 S 3 and Cr 3 S 4 Insoluble sulfides. After static precipitation, the turbid solution of the reaction product was allowed to stand for 1 hour, and the precipitate was recovered. The effluent water quality h...

Embodiment 2

[0032] Containing Cr in the electroplating workshop of Fujian Putian Mold Factory 6+ Wastewater is treated, its Cr 6+ The concentration was 175.6 mg / l. The pyrite ore is pulverized and passed through a 200-mesh sieve to obtain the pyrite ore powder; the modifier polycarboxylic acid is added to the pyrite ore powder in an amount of 2.5% of the weight of the pyrite ore powder, and the mixture is evenly stirred. Obtain improved pyrite ore powder. Add the improved pyrite ore powder into the waste water containing hexavalent chromium according to the addition amount of 40g / l waste water, the pH value of the waste water containing hexavalent chromium is 3, fully stir, the reaction time is 1 hour, and the reaction forms Cr 2 S 3 and Cr 3 S 4 Insoluble sulfides. After static precipitation, the turbid solution of the reaction product was allowed to stand for 2 hours, and the precipitate was recovered. Cr after treatment 6+ When the concentration is below 0.002mg / l, the effluent...

Embodiment 3

[0034] Cr content of Changsha Chromium Salt Plant 6+ Wastewater is treated, its Cr 6+ The concentration is 148mg / l. Pyrrhotite ore (commercially available) is pulverized and passed through a 300-mesh sieve to obtain pyrrhotite ore powder; the modifier polycarboxylic acid is added to the pyrrhotite ore powder in an amount of 2.0% of the weight of the powder, and stir evenly to obtain the improved pyrrhotite ore powder. Add the improved pyrrhotite ore powder into the waste water containing hexavalent chromium according to the addition amount of 30g / l waste water, the pH value of the waste water containing hexavalent chromium is 4, fully stir, the reaction time is 1.5 hours, and the reaction forms Cr 2 S 3 and Cr 3 S 4 Insoluble sulfides. After standing still for precipitation, the cloudy solution of the reaction product was left standing for 2.5 hours, and the precipitate was recovered. Cr after treatment 6+ Concentration below 0.017mg / l, except Cr 6+ The rate reached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com