Cyanogen-containing tailing slag treatment method

A technology of tailings slag and ore pulp, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of no advanced and mature cyanide-containing waste slag treatment methods, and achieve industrial application , The effect of stable system operation and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

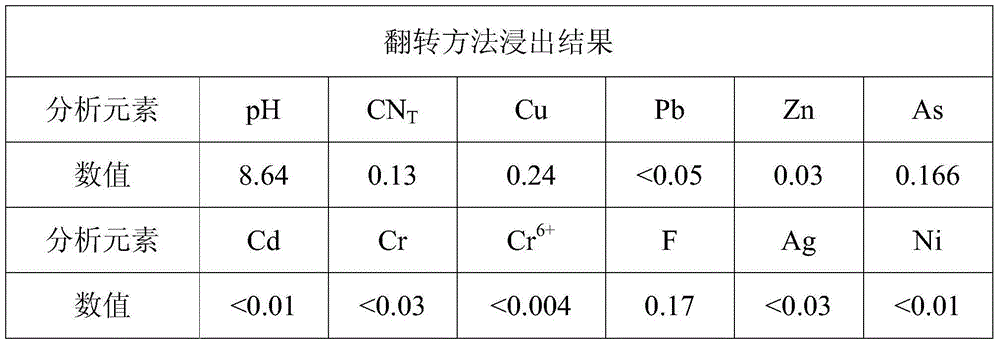

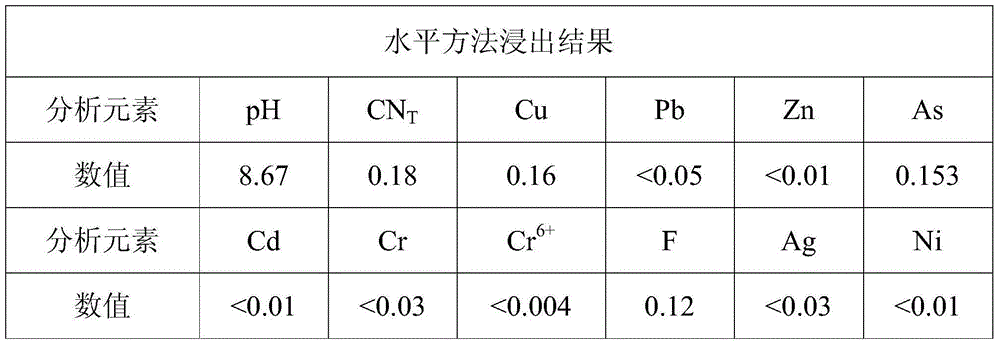

[0038] Cyanide tailings slag from a gold mine, CN T 413.47mg / kg, Cu 2+ It is 82.56mg / kg, COD is 187.25mg / kg, and also contains trace amounts of other heavy metal ions. Take 1kg of tailings slag and put it in the stirring tank, add 1kg of water, stir and adjust the slurry for 30 minutes, then place the evenly adjusted slurry in the ozone oxidation tank, pass through ozone for oxidation reaction for 1 hour, the amount of ozone introduced is 1.46g, and then Put the ozonated pulp in a stirring tank, add dilute sulfuric acid to adjust the pH value of the pulp to 8.0, then 6mL of 35% hydrogen peroxide, filter after 30min, pass the slurry into the biological decyanide treatment reactor, and connect it to the For cyanogen bacteria, air is introduced, the gas-liquid ratio is 3:1, and the treatment is 2 hours. The treated slurry is pumped into the upflow biofilter with a gas-liquid ratio of 3:1, and the treatment is 1 hour. The filtered tailings slag was analyzed by toxicity leaching ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com