Waterproof bonding agent for ignition powder and preparation method of waterproof bonding agent

An adhesive and ignition powder technology, which is applied in the interdisciplinary field of energy and chemical industry, can solve the problem that ignition powder is easily damped, and achieve the effects of abundant raw materials, improved adhesion, and improved waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

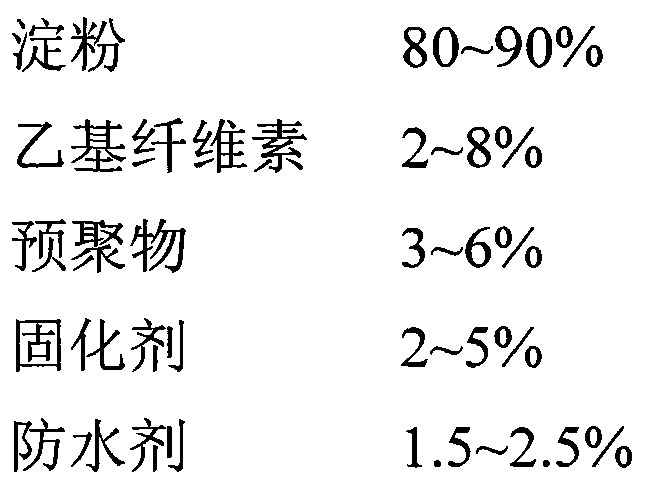

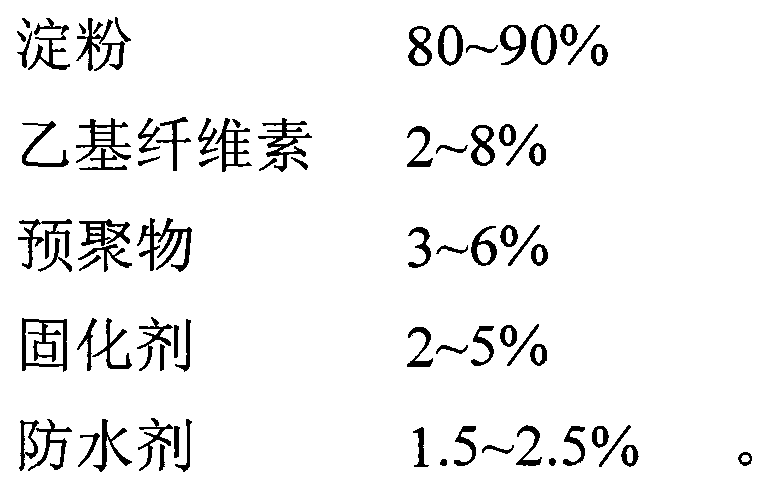

[0025] A waterproof adhesive for ignition medicine, the mass fraction of each component in its formula is: 80g corn starch, 8g ethyl cellulose, 5g polynitromethyl oxetane, 5g gypsum, 2g dimethyl diethyl Oxysilane;

[0026] A preparation method of a waterproof adhesive for ignition powder, the specific steps are as follows:

[0027] 1) Weigh 80g cornstarch, 8g ethylcellulose, 5g polynitromethyloxetane, 5g gypsum, 2g dimethyldiethoxysilane;

[0028] 2) Put 80g of cornstarch into 240g of distilled water and stir for 40min to form a milky white suspension;

[0029] 3) Heat the suspension to 60°C, form a uniform paste, add ethyl cellulose, polynitromethyl oxetane, stir at 400r / min for 30 minutes, then add gypsum, dimethyl diethyl Oxysilane, stirred for 3h;

[0030] 4) Cool the solution of 3) to room temperature to obtain a waterproof adhesive.

[0031] The water-repellent rate of the waterproof adhesive is 99%, the friction sensitivity is 5.8%, the impact sensitivity is 15.3%, ...

Embodiment 2

[0033] A waterproof adhesive for ignition medicine, the mass fraction of each component in its formula is: 90g sweet potato starch, 2g ethyl cellulose, 3g polyglycidyl azidoglycerol ether, 3g calcium chloride, 2g silane coupling agent;

[0034] A preparation method of a waterproof adhesive for ignition powder, the specific steps are as follows:

[0035] 1) Weigh 90g sweet potato starch, 2g ethyl cellulose, 3g polyglycidyl azidoglyceryl ether, 3g calcium chloride, 2g silane coupling agent;

[0036] 2) Put 90g sweet potato starch into 450g distilled water and stir for 90min to form a milky white suspension;

[0037] 3) Heat the suspension to 70°C, form a uniform paste, add ethyl cellulose and polyglycidyl azide ether, and add calcium chloride and silane coupling agent after 30 minutes at a stirring speed of 400r / min. Stir for 2h;

[0038] 4) Cool the solution of 3) to room temperature to obtain a waterproof adhesive.

[0039] The water-repellent rate of the waterproof adhesiv...

Embodiment 3

[0041] A kind of waterproof adhesive for ignition medicine, the mass fraction of each component in its formula is: 81g corn starch, 7g ethyl cellulose, 5g polyglycidyl nitrate, 4.5g gypsum, 2.5g dimethyl diethoxy base silane;

[0042] A preparation method of a waterproof adhesive for ignition powder, the specific steps are as follows:

[0043] 1) Weigh 81g cornstarch, 7g ethylcellulose, 5g polyglycidyl nitrate, 4.5g gypsum, 2.5g dimethyldiethoxysilane;

[0044] 2) Put 81g of cornstarch into 260g of distilled water and stir for 45min to form a milky white suspension;

[0045] 3) Heat the suspension to 90°C to form a uniform paste, then add ethyl cellulose and polyglycidyl nitrate, and add gypsum and dimethyldiethoxysilane after 30 minutes at a stirring speed of 300r / min , stirred for 1.5h;

[0046] 4) Cool the solution of 3) to room temperature to obtain a waterproof adhesive.

[0047] The water-repellent rate of the waterproof adhesive is 99%, the friction sensitivity is 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com