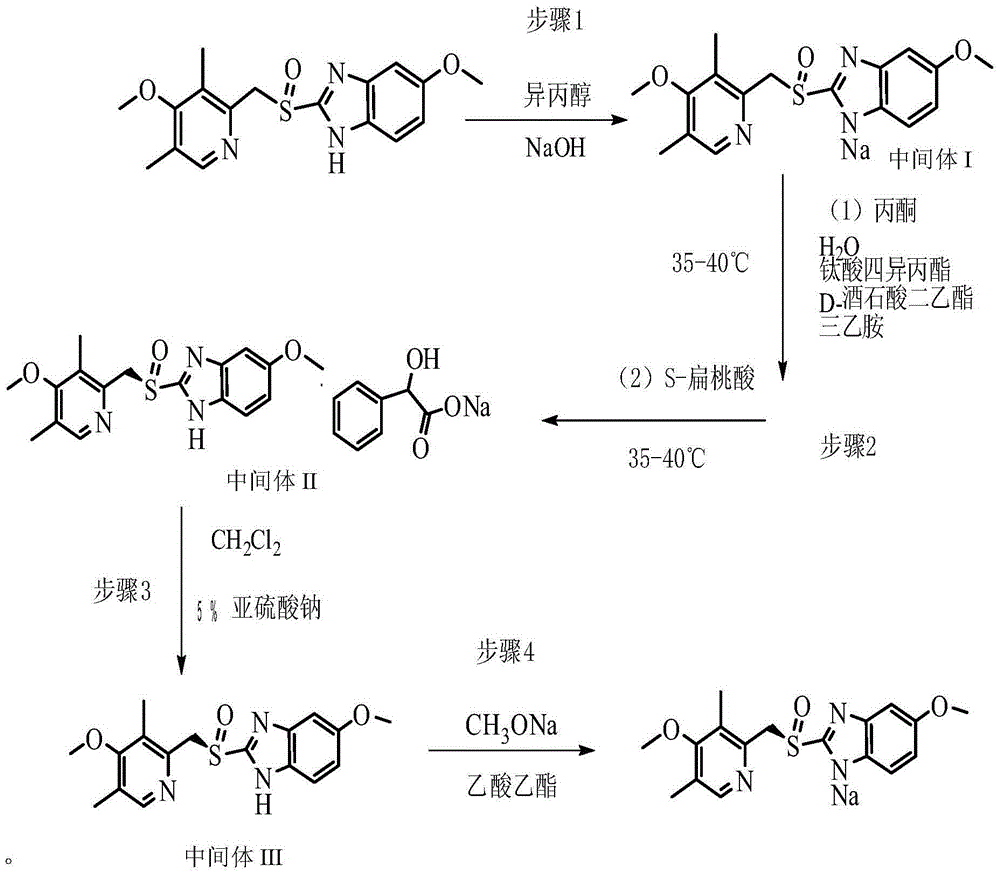

Preparation method of esomeprazole sodium

A technology of esomeprazole sodium and esomeprazole, which is applied in the field of chemistry and can solve the problems of inapplicability to large-scale production, many reagents, and cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0036] Experimental example 1, the impact of different solvents on the yield of intermediate I

[0037] 1. Purpose: To investigate the influence of selecting different solvents on the yield of intermediate I omeprazole sodium.

[0038] 2. Method: 4 experiments in parallel, each experiment is as follows

[0039] Put 17.3g of sodium hydroxide into 400ml of solvent A, and stir at room temperature for 2h until all the sodium hydroxide particles are dissolved. Add 100g of omeprazole to the reaction solution, stir at room temperature for 2 to 3 hours, a large amount of white precipitate appears, filter, wash the filter cake with 100ml of ethyl acetate, weigh and calculate the yield after drying, which is intermediate I omeprazole azole sodium.

[0040] Wherein the solvent A is ethanol (adding disodium hydrogen phosphate, test 1-1), methanol (test 1-2), isopropanol (test 1-3), n-butanol (test 1-4).

[0041] 3. Results and conclusions

[0042] The differences between the specific ex...

experiment example 2

[0046] Experimental example 2, the influence of sodium hydroxide consumption on intermediate I yield

[0047] One, purpose: investigate the influence of the consumption of sodium hydroxide on intermediate I omeprazole sodium yield.

[0048] 2. Method: 5 experiments in parallel, each experiment is as follows

[0049] Put different amounts of sodium hydroxide into 400ml of isopropanol, and stir at room temperature for 2 hours until all the sodium hydroxide particles are dissolved. Add 100g of omeprazole to the reaction solution, stir at room temperature for 2 to 3 hours, a large amount of white precipitate appears, filter, wash the filter cake with 100ml of ethyl acetate, weigh and calculate the yield after drying, which is intermediate I omeprazole azole sodium.

[0050] Wherein the feeding amount of sodium hydroxide is respectively 11.6g (1.0eq, experiment 2-1), 14.5g (1.25eq, experiment 2-2), 17.3g (1.5eq, experiment 2-3), 20.2g (1.75eq , Runs 2-4), 11.6 g (23.2 eq, Runs 2...

experiment example 3

[0057] Experimental example 3, the influence of different solvents on product isomers in the preparation process of intermediate II

[0058] 1. Purpose: To investigate the influence of different solvents on the product isomers during the preparation of intermediate II.

[0059] 2. Method: 4 experiments were performed in parallel, and the operation of each experiment was as follows:

[0060] Put 400ml of different solvents (cyclohexane, n-hexanol, n-propanol, ethyl acetate) and 10.5g of purified water into the reaction flask, add 106g of omeprazole sodium under stirring at room temperature, and continue stirring at room temperature for 1 to 2 hours. Filter, and filter the solvent as dry as possible to obtain omeprazole sodium hydrate, and ensure that its water content is within the range of 1.5-2.0%. The omeprazole sodium hydrate that obtains is added in the reaction bottle that fills 1000ml acetone. Control the reaction temperature at 35-40°C, add D-diethyl tartrate, tetrais...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com