Method for enhancing production yield and rate of esomeprazole

A kind of technology of esomeprazole and product yield, applied in the field of drug synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

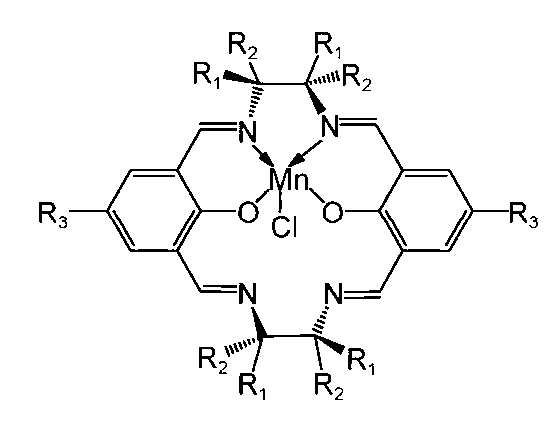

Embodiment 1

[0020] Weigh 100g of sulfide with an electronic balance, dissolve it in 500ml of dichloromethane, stir at 25-30°C for 30min, add chiral catalyst 0.091molMn (salen), 0.213molD-(-)diethyl tartrate, and stir at 55°C for 25min. Lower the temperature to 15~25°C, add 50g of cumene hydroperoxide, and complete the oxidation in 20 minutes. Add n-hexane, filter out Mn (salen), then distill off dichloromethane and n-hexane, and finally add 600ml of acetone to dissolve esomeprazole at room temperature, and then raise the temperature to 53°C for crystallization. Obtain about 92g of esomeprazole fine product, and it is 99.8% to obtain esomeprazole content by high performance liquid phase detection.

Embodiment 2

[0022] Weigh 50g of sulfide with an electronic balance, dissolve it in 250ml of dichloromethane, stir at 25-30°C for 30min, add chiral catalyst 0.045molMn (salen), 0.106molD-(-)diethyl tartrate, and stir at 55°C for 25min. Lower the temperature to 15-25°C, add 25g of cumene hydroperoxide, and complete the oxidation in 20 minutes. Add n-hexane, filter out Mn (salen), then distill off dichloromethane and n-hexane, and finally add 300ml of acetone to dissolve esomeprazole at room temperature, and heat up to 53°C for crystallization after dissolution. Obtain about 45g of esomeprazole fine product, and it is 99.8% to obtain esomeprazole content by high performance liquid phase detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com