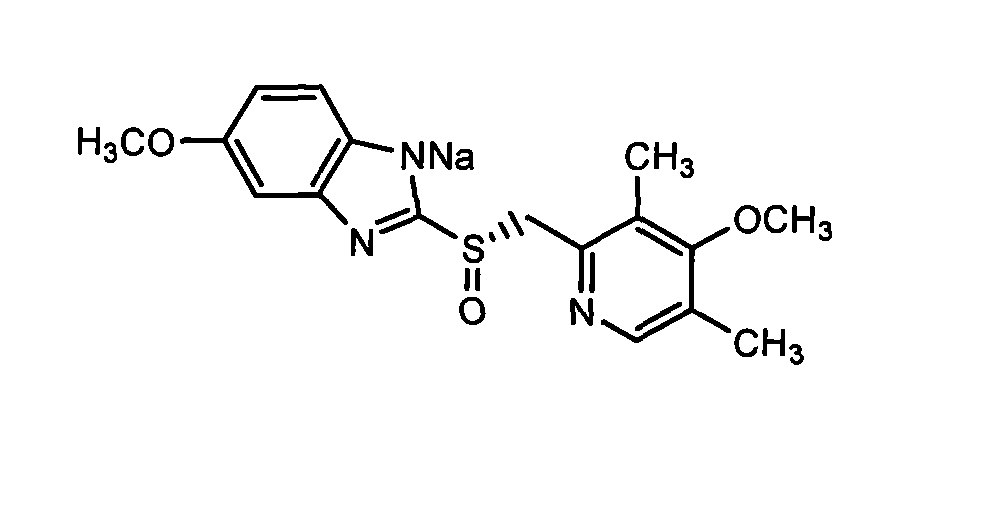

Preparation method of high-purity esomeprazole sodium salt

A technology of esomeprazole salt and meprazole salt, which is applied in the field of compound salt purification, can solve the problems of high production cost and large amount of solvent, and achieve the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

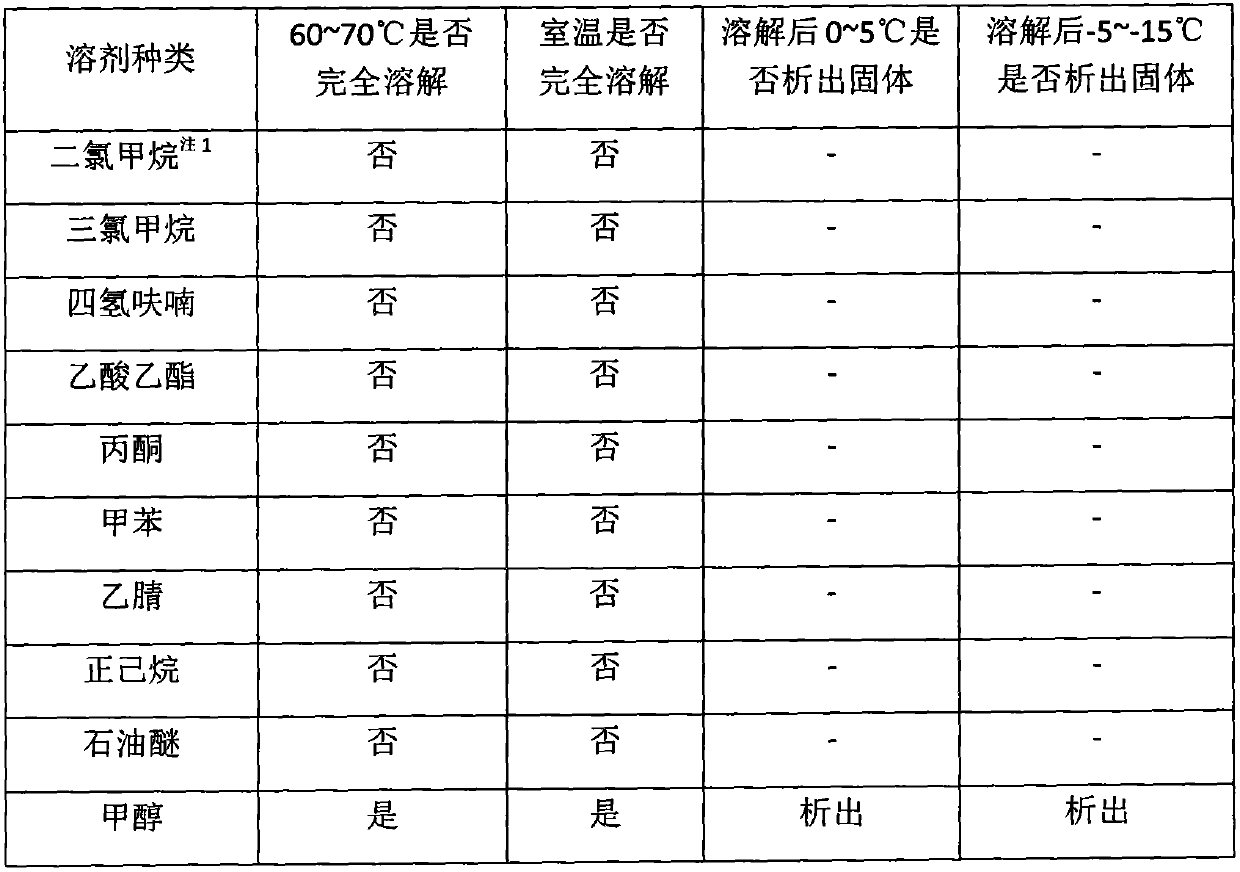

Method used

Image

Examples

Embodiment 1

[0043] Take 100 grams of esomeprazole sodium crude product, add 160 grams of methanol, stir and dissolve at 25°C. After dissolving, cool down to 0°C and stir for 2 hours, then filter. After drying the filter cake at 80-85°C for 2 hours, add 200 grams of acetone to the product, add and reflux for 2 hours, and cool to room temperature. Filtrate, and dry the filter cake at 80-85°C for 2 hours to obtain 54 grams of esomeprazole sodium. Checked by HPLC, the single impurity is less than 0.1%, and the purity is greater than 99.7%. Moisture content (Karl Fischer method) 0.31, placed under the condition of relative humidity 80% for 12 hours, water content 3.8%.

[0044] HPLC method:

[0045] Stationary phase: C8 column (4.6×150mm, 5μm)

[0046] Mobile phase: phosphate buffer (weigh 1.4g sodium dihydrogen phosphate pentahydrate into 1000ml water, adjust pH=7.90 with phosphoric acid)-acetonitrile (73:27)

[0047] Detection wavelength: 280nm

[0048] Flow rate: 1.0ml / min

[0049] Inj...

Embodiment 2

[0052] Take 100 grams of esomeprazole sodium crude product, add 160 grams of methanol, stir and dissolve at 20°C. After dissolving, cool down to -5°C and stir for 2 hours, then filter. After drying the filter cake at 80-85°C for 2 hours, add 200 grams of acetone to the product, add and reflux for 2 hours, and cool to room temperature. Filter, and dry the filter cake at 80-85° C. for 2 hours to obtain 62 grams of esomeprazole sodium. Checked by HPLC, the single impurity is less than 0.1%, and the purity is greater than 99.7%. Moisture content (Karl Fischer method) 0.24, placed under the condition of relative humidity 80% for 12 hours, water content 4.3%.

[0053] The HPLC method is the same as in Example 1.

Embodiment 3

[0055] Take 100 grams of esomeprazole sodium crude product, add 300 grams of methanol, stir and dissolve at 30°C. After dissolving, cool down to 0°C and stir for 3 hours, then filter. After drying the filter cake at 80-85°C for 2 hours, add 200 grams of acetonitrile to the product, add and reflux for 3 hours, and cool to room temperature. Filtrate, and dry the filter cake at 80-85° C. for 2 hours to obtain 48 grams of esomeprazole sodium. Checked by HPLC, the single impurity is less than 0.1%, and the purity is greater than 99.7%. Moisture content (Karl Fischer method) 0.31, placed under the condition of relative humidity 80% for 12 hours, water content 3.9%.

[0056] The HPLC method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com