A kind of silane coupling agent intermediate and its application in light curing silica sol

A silane coupling agent and intermediate technology, which is applied in the field of polymer materials, can solve the problem of poor fixation of silicon oxide nanoparticles, failure to meet application performance requirements, scratch resistance of the coating surface, and insufficient wear resistance of the coating body and other problems, to achieve the effects of reducing the residue of small molecule photoinitiators, improving the efficiency of polymerization and crosslinking, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

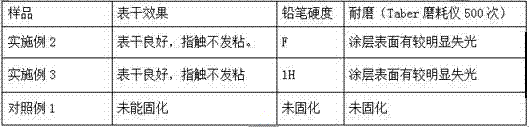

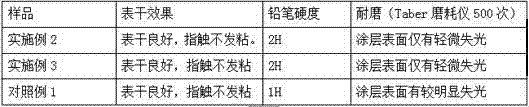

Examples

preparation example Construction

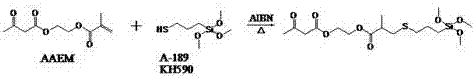

[0039] Preparation of acetoacetate functionalized silane coupling agent 1

[0040] Add 152.37g (0.64mol) 3-mercaptopropyltriethoxysilane and 6.3g azobisisobutyronitrile into the flask, stir well to dissolve azobisisobutyronitrile, then add the mixture to the dropping funnel middle. Add 86.21g (0.61mol) of allyl acetoacetate into a 250ml reaction bottle, start stirring, heat up to 40°C, and start to drop the mixture of 3-mercaptopropyltriethoxysilane and azobisisobutyronitrile , The dropping time is 2h. After the dropwise addition of the mixture was completed, the temperature was raised to 60° C. for 3 hours, and 0.5 g of azobisisobutyronitrile was added. Continue to keep the temperature at 60°C for 3h. The obtained product is slightly yellowish viscous liquid. 1HNMR(CDCL3,PPM):0.59(2H,t),1.22(9H,t), 1.7(2H,m), 1.94(2H,m), 2.09(3H,s), 2.44(4H,t), 3.41 (2H,s), 3.83(6H,q), 4.08(2H,t).

[0041] Preparation of acetoacetate functionalized silane coupling agent 2

[0042] Add 11...

Embodiment 1

[0044] Embodiment 1 Preparation of silane coupling agent intermediate 1

[0045] Add 165.36g trimethylolpropane triacrylate (acrylate group 1.67mol), 84.65g acetoacetate functionalized silane coupling agent 1 (acetoacetate group 0.21mol), 1.1 gDBU, start stirring, and slowly heat up to a constant temperature of 80°C. Constant temperature up to 6h, discharge. The product is slightly yellowish viscous liquid.

Embodiment 2

[0046] Example 2 Preparation of photocurable silica sol 1

[0047] Add 7.42g of the silane coupling agent intermediate 1 of Example 1 and 222.6g of tetraethoxysilane into a 250ml reaction bottle, start stirring, add 1.11g of concentrated hydrochloric acid, and add 18g of ethanol to speed up the stirring speed. After stirring at room temperature for 5 hours, slowly heat up to a constant temperature of 75°C, and turn on the vacuum to remove small molecules. The vacuum degree should be ≤ -0.098MPa. After evacuating for 1 hour, stop the vacuum and discharge the material. The product is a yellowish viscous liquid with a viscosity of 9600cps (30°C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com