Method for comprehensive recovery of valuable metals in electroplating sludge

A technology for electroplating sludge and valuable metals, applied in the direction of improving process efficiency, etc., can solve problems such as low yield, high cost, secondary pollution, etc., and achieve high economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

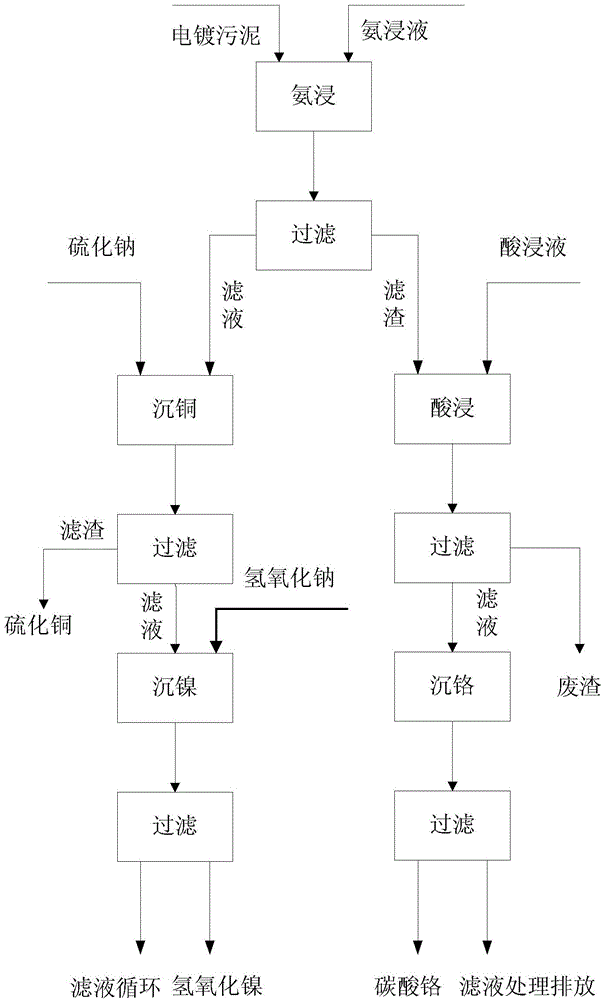

Method used

Image

Examples

Embodiment 1

[0040]Get electroplating sludge 100kg (dry basis, its composition is: Ni is 5.1%, Cu is 5.7%, Cr is 6.3%), joins in the 300L ammonia immersion solution (the concentration of ammonia is 8%), adjusts The temperature was raised to 40°C, stirred for 3 hours, and the filtrate and filter residue were obtained through plate and frame pressure filtration. Add 80L of 10% sodium sulfide to the ammonia leaching filtrate at room temperature, raise the temperature to 80°C and stir for 30 minutes, filter after cooling, wash and dry the filter residue to obtain 8.1kg of crude copper sulfide; add 10% sodium hydroxide to the filtrate at room temperature The solution was 110L, heated to 80°C and stirred for 30 minutes, filtered after cooling, and the filter residue was washed and dried to obtain 9.3kg of crude nickel hydroxide. The ammonia leached filter residue was added to 15% sulfuric acid, and the pH was adjusted to 3.0-3.5 at 50° C., stirred for 90 minutes, and filtered to obtain the filtr...

Embodiment 2

[0041] Embodiment 2: get the electroplating sludge 1000kg (dry base, its composition: Ni is 5.9%, Cu is 5.5%, Cr is 6.6%) of the electroplating sludge of certain electroplating enterprise, joins in 3m 3 In the ammonia immersion solution (the concentration of ammonia is 10%), adjust the temperature to 30° C., stir for 3 hours, and obtain the filtrate and filter residue through plate and frame pressure filtration. Add 550L of 15% sodium sulfide to the ammonia leaching filtrate at room temperature, raise the temperature to 80°C and stir for 30 minutes, filter after cooling, wash and dry the filter residue to obtain 79kg of crude copper sulfide; add 1100L of 10% sodium hydroxide solution to the filtrate at room temperature , heated up to 80°C and stirred for 30 minutes, filtered after cooling, and the filter residue was washed and dried to obtain 91 kg of crude nickel hydroxide. The ammonia leached filter residue was added to 15% sulfuric acid, at 50°C, the pH was adjusted to be b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com