Zinc oxide photo-anode film and preparation method and application thereof

A photoanode, zinc oxide technology, applied in electrodes, gaseous chemical plating, coatings, etc., can solve the problems of the universal impact of ZnO photoanode materials, unfavorable large-area deposition of thin films, cumbersome preparation methods, etc., and achieve the preparation time. The effect of short, improving universality and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

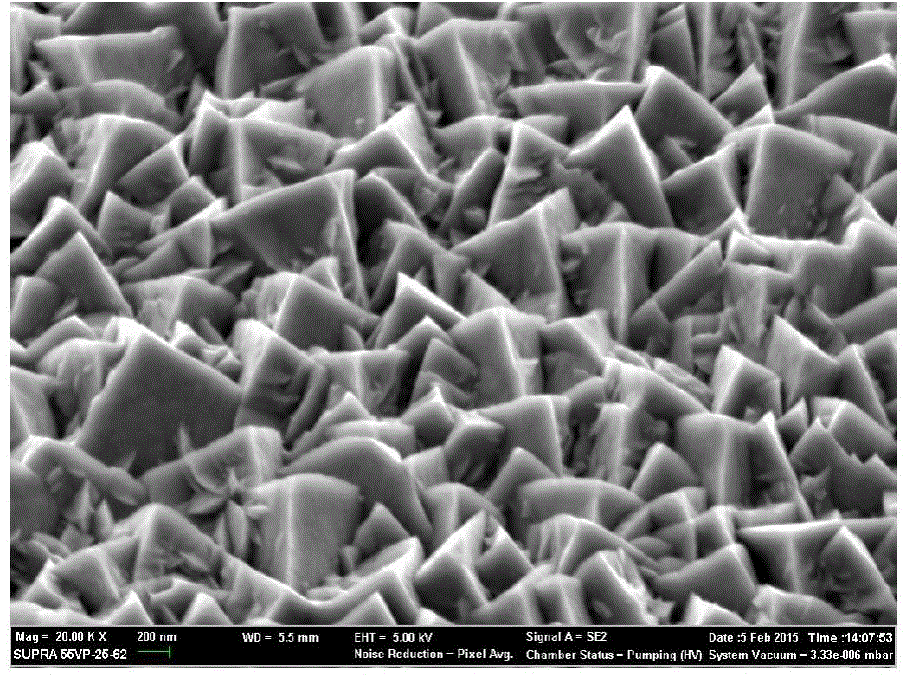

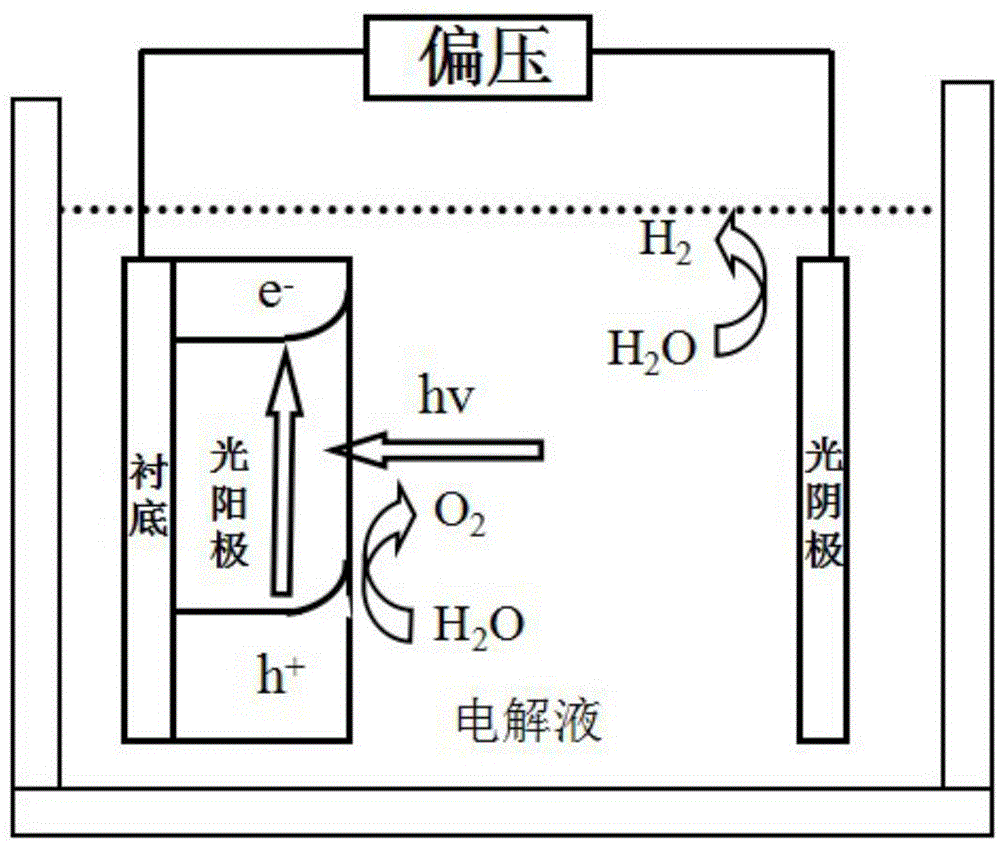

[0017] A zinc oxide photoanode film is prepared by depositing on the surface of a textured FTO substrate by MOCVD, wherein the thickness of the FTO layer is 600nm, the centimeter resistance is 20Ω, and the optical band gap is 2eV; the thickness of the ZnO photoanode film is 1.5- 7.5μm, centimeter resistance is 500Ω, optical bandgap width is 3.2eV; its preparation method is to use zinc source liquid as diethyl zinc (DEZn), oxygen source liquid as water and doping source gas as B 2 h 6 , the carrier gas carrying gas is Ar gas, comprising the following steps:

[0018] 1) The FTO substrate was ultrasonically cleaned in a container of 99.7% absolute ethanol for 30 min, and then was cleaned with high-purity N 2 Blow dry, and use high-temperature tape to reserve an electron transport electrode that does not deposit ZnO on the FTO substrate;

[0019] 2) Place the above-treated FTO samples in the chamber of a single-chamber MOCVD deposition system to deposit thin films. Base zinc (D...

Embodiment 2

[0025] A preparation method of a zinc oxide photoanode film is basically the same as in Example 1, except that the deposition time in step 2) is 75min, the thickness of the ZnO film is 2.5 μm, and the " Pyramid-like zinc oxide (ZnO) photoanode film.

[0026] The surface morphology of the zinc oxide photoanode prepared by this method is the same as that in Example 1.

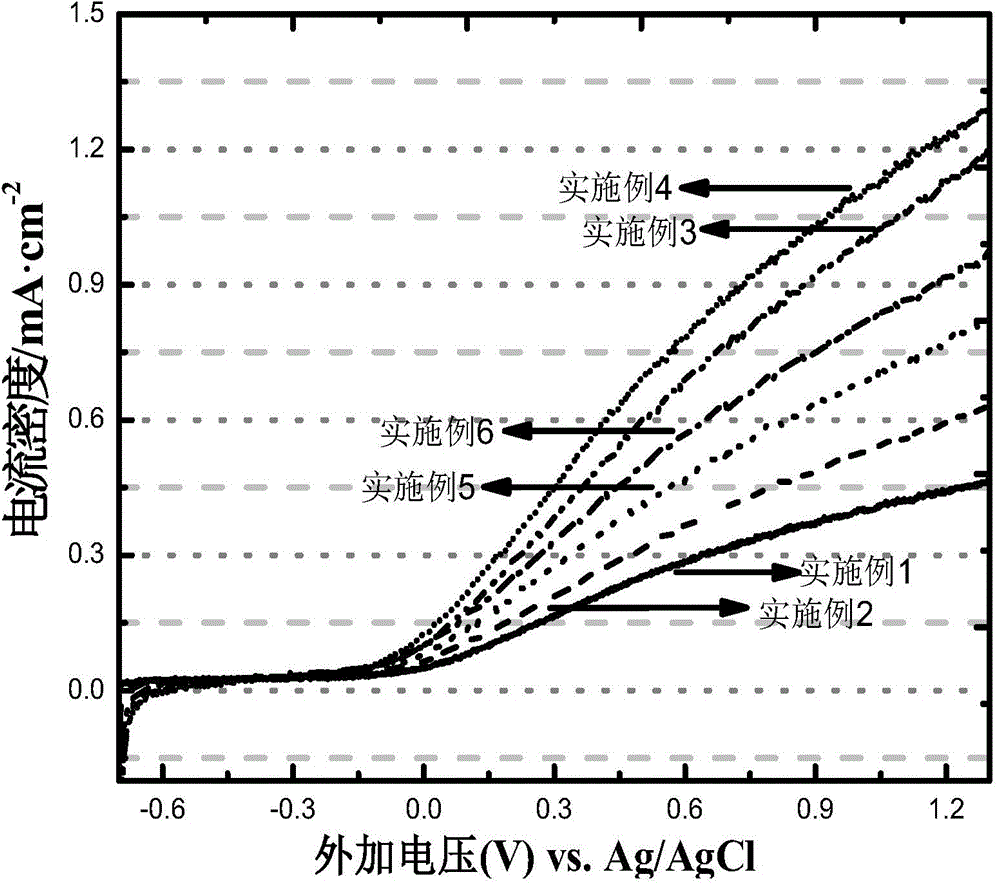

[0027] The application method of the prepared zinc oxide photoanode film is the same as in Example 1, and the photocurrent density curve of the zinc oxide photoanode prepared by this method is as follows image 3 As shown, the figure shows that: MOCVD-ZnO is used as a photoanode for photoelectrochemical cells, and the photocurrent density obtained under 0.62V vs.Ag / AgCl is 0.37mA / cm 2 .

Embodiment 3

[0029] A preparation method of a zinc oxide photoanode film is basically the same as in Example 1, except that the deposition time in step 2) is 125min, and the thickness of the ZnO film is 5.5 μm. Pyramid-like zinc oxide (ZnO) photoanode film.

[0030] The surface morphology of the zinc oxide photoanode prepared by this method is the same as that in Example 1.

[0031] The application method of the prepared zinc oxide photoanode film is the same as in Example 1, and the photocurrent density curve of the zinc oxide photoanode prepared by this method is as follows image 3 As shown, the figure shows that: MOCVD-ZnO is used as a photoanode for photoelectrochemical cells, and the photocurrent density obtained under 0.62V vs.Ag / AgCl is 0.71mA / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Optical bandgap | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com