Door and window connector, assembly type passive house external wall, and door and window installation method thereof

A technology of connectors and passive houses, applied in the direction of walls, windows/doors, building components, etc., to achieve the effect of accurate installation standards and high production precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

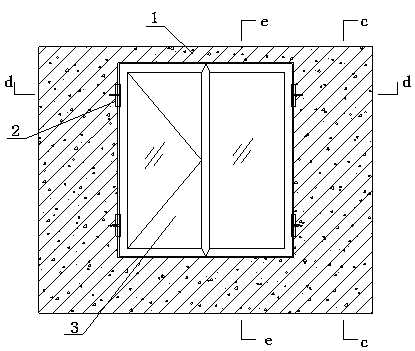

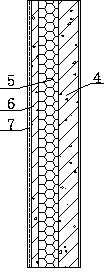

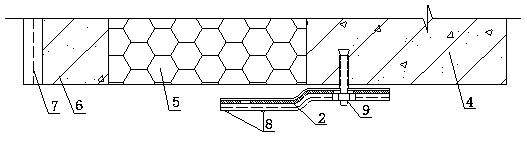

[0072] Such as Figure 1-8 As shown, a prefabricated passive house exterior wall with doors and windows installed, it includes a rectangular sheet wall with a door and window installation hole, the wall includes an inner page wall 4 and an outer page wall 6, and the inner page wall 4 and the outer page wall In the middle of the page wall 6, there is an insulation board as the insulation layer 5; the insulation layer 5 adopts the high-efficiency insulation material GPES rigid foam composite plastic insulation board or polyurethane modified polyisocyanurate with a thermal conductivity of ≤0.022 w / (m K). Rigid foam composite plastic insulation board; the insulation layer of the door and window installation hole is an L-shaped cross-section structure. The horizontal part of the L-shaped cross-section structure of the layer is bonded, and the height of the vertical part of the L-shaped cross-section structure of the insulation layer is 2 / 3 of the side of the door and window frame, ...

Embodiment 2

[0082] Such as Figure 9-11 Shown, a kind of door and window connector, it comprises the main body 27 that has zigzag flap shape, is provided with the raised band 28 that cross-section is n-shaped symmetrically on both sides of main body 27, is provided with positioning at the top of raised band 28 at one end of main body 27. Raised 8. The body 27 is provided with a through hole. The through hole is an oval hole. Such as Figure 12-14 As shown, an outwardly extending ear plate 29 is provided on the raised belt 28 , and the positioning protrusion 8 and the ear plate 29 are located at the same end of the body 27 . Through holes are provided on the lug plate 29 . The body 27 of the zigzag folded sheet of the connector has a height of 12 mm, a width of 60 mm, and a length of 200 mm, and is made of 3 mm steel plate.

Embodiment 3

[0083] Embodiment 3: A method for installing doors and windows on the exterior wall of a prefabricated passive house, characterized in that it includes the following steps:

[0084] (1) Make door and window openings and door and window frames according to the relationship between the size of the door and window openings and the size of the door and window frames:

[0085] Door and window opening width = (door and window width + 2 × a) ± 1mm

[0086] Door and window opening height = (door and window width + c + b) ± 1mm

[0087] a: The distance from the left outer side of the door and window frame to the left side of the door and window opening or the distance from the right outer side of the door and window frame to the right side of the door and window opening is 15±1mm; b: The distance from the lower outer side of the door and window frame to the bottom of the door and window opening is 35±1mm, of which the height dimension of the window frame additional profile 21 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com