Colored photosensitive resin composition and color filter containing the same

A technology of photosensitive resin and composition, applied in optical filters, photosensitive materials for optomechanical equipment, optics, etc., which can solve problems such as difficulty in providing high contrast and inability to use color filters effectively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0085] Preparation Example 1: Preparation of Binder Resin

[0086] Prepare a flask equipped with a stirrer, thermometer, reflux condenser, dropper, and nitrogen inlet. Preparation of monomer drops: 74.8g (0.20mol) of benzylmaleimide, 43.2g (0.30mol) of acrylic acid, 118.0g (0.50mol) of vinyl toluene, tert-butyl peroxy-2-ethylhexyl 4 g of acid ester and 40 g of propylene glycol monomethyl ether acetate (PGMEA) were mixed and stirred. Preparation of chain transfer agent drops: 6 g of n-dodecanemercaptan and 24 g of PGMEA were mixed and stirred. Then, 395 g of PGMEA was added to the above-mentioned flask, and the atmosphere of the flask was changed from air to nitrogen, and the temperature of the flask was raised to 90° C. while stirring. Monomer and chain transfer agent are dropped sequentially from the dropper. Each drop was performed for 2 hours while maintaining the temperature at 90°C. After 1 hour, the temperature was raised to 110° C. and held for 3 hours. Then, a mix...

Embodiment 1~5 and comparative example 1~4

[0098] Examples 1-5 and Comparative Examples 1-4: Preparation of Colored Photosensitive Resin Composition and Color Filter

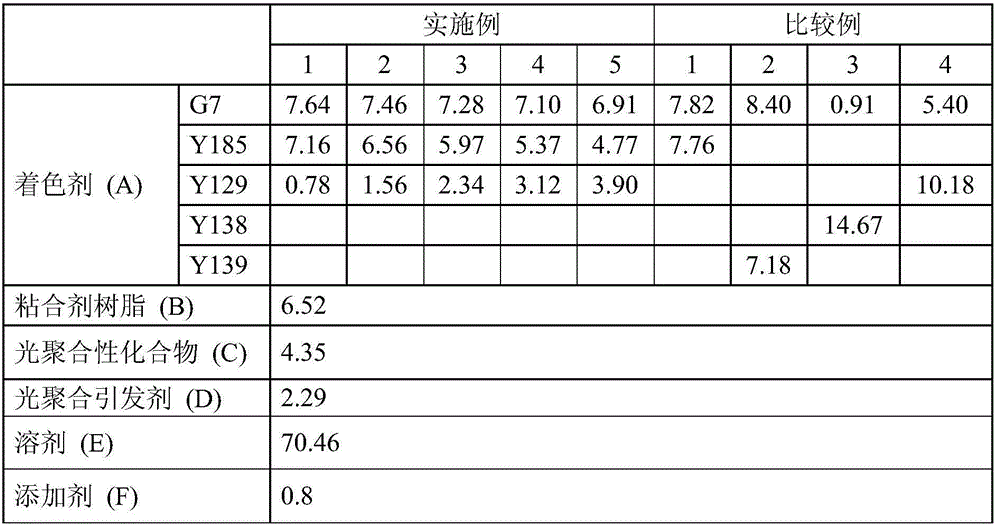

[0099] The colored photosensitive resin composition was prepared by mixing the components in the proportions (unit: weight %) listed in Table 1 below.

[0100] Table 1

[0101]

[0102] Each group in above-mentioned table 1 is as follows:

[0103] G7: Pigment Green 7

[0104] Y185: Pigment yellow 185

[0105] Y129: Pigment Yellow 129

[0106] Y138: Pigment yellow 138

[0107] Y139: Pigment yellow 139

[0108] B: Preparation of the binder resin of Example 1

[0109] C: Dipentaerythritol hexaacrylate (KAYARAD DPHA, Nippon Kayaku)

[0110] D: 2-benzyl-2-dimethylamino-1-(4-morpholinophenyl)butan-1-one (Irgacure 369, Ciba Specialty Chemical)

[0111] E: Propylene glycol monomethyl ether acetate

[0112] F: Acrylic pigment dispersant (Disper byk-2001, BYK-Chemie)

experiment example 1-1

[0114] Experimental Example 1-1: Evaluation of Brightness, Contrast and Color Intensity

[0115] The colored photosensitive resin compositions prepared in Examples 1-5 and Comparative Examples 1-4 were used to prepare colored layers. Specifically, each colored photosensitive resin composition was applied on a glass substrate by spin coating, and the glass substrate was placed on a hot plate maintained at 100° C. for 3 minutes to form a thin film on the glass substrate. Subsequently, use a 1KW high-pressure mercury lamp containing g, h and i rays at 100mJ / cm 2 Each film was subjected to UV irradiation. No special filters were used.

[0116] Each UV-irradiated film was immersed in a KOH alkaline solution (pH 10.5) as a developer for 2 minutes. After development, the film-coated glass was rinsed with distilled water and dried with nitrogen, followed by heating in an oven at 200° C. for 30 minutes to provide a colored layer having a thickness of 1˜5 μm.

[0117] Each sample wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com