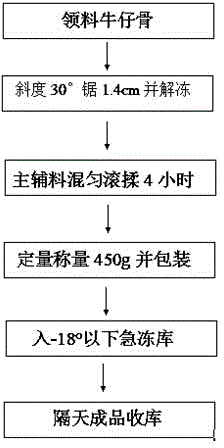

Method for preparing beef short ribs

The technology of a cowboy bone and a bone sawing machine is applied in the field of food processing, which can solve the problems of difficult chewing, dry taste, and insufficient freshness of the steak, and achieve the effects of convenient eating, improved freshness, and easy chewing and digestion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In the embodiment of the present invention, a method for preparing cowboy bones, 500 kg of cowboy bones raw materials are taken back and sawed into flakes with a bone sawing machine, with a slope of 30° and a thickness of 1.3-1.5 cm. After 70% thawing, pour into the tumbler and add ingredients A and B. Before adding ingredients A and B, mix ingredients A and B evenly with a beater; knead for 4 hours, then add 10kg of cornstarch and stir evenly. Quantitative packaging, where the tumbling speed is 3r / min. A ingredients include: 1.6kg of edible salt, 0.6kg of white sugar, 3.4g of food powder, 1.9kg of chicken powder, 0.5kg of sodium diacetate, 0.1kg of terry phosphorus crisp, 0.3kg of special phosphorus, 1.3kg of loose meat powder, D- Erythorbic acid 1.4kg. Ingredients B include: 75g of red pepper, 0.9kg of black pepper, 4.9kg of cooking wine, 0.9kg of Beijing shochu, 72kg of vegetable juice, and 104kg of water. Crushed ice is also added to B ingredient in summer. Durin...

Embodiment 2

[0023] In the embodiment of the present invention, a method for preparing cowboy bones, 500 kg of cowboy bones raw materials are taken back and sawed into flakes with a bone sawing machine, with a slope of 30° and a thickness of 1.3-1.5 cm. After 70% thawing, pour into the tumbler and add ingredients A and B. Before adding ingredients A and B, mix ingredients A and B evenly with a beater; knead for 4 hours, then add 12kg of cornstarch and stir evenly. Quantitative packaging, where the tumbling speed is 3r / min. A ingredients include: 1.8kg of edible salt, 0.8kg of white sugar, 3.6g of food powder, 2.1kg of chicken powder, 0.7kg of sodium diacetate, 0.3kg of terry phosphorus crisp, 0.5kg of special phosphorus, 1.5kg of loose meat powder, D- Erythorbic acid 1.6kg. B ingredients include: red pepper 85g, black pepper 1.1kg, cooking wine 5.1kg, Beijing shochu 1.1kg, vegetable juice 73kg, water 106kg. Crushed ice is also added to B ingredient in summer. During the assembly line op...

Embodiment 3

[0025] In the embodiment of the present invention, a method for preparing cowboy bones, 500 kg of cowboy bones raw materials are taken back and sawed into flakes with a bone sawing machine, with a slope of 30° and a thickness of 1.3-1.5 cm. After 70% thawing, pour into the tumbler and add ingredients A and B. Before adding ingredients A and B, mix ingredients A and B evenly with a beater; knead for 4 hours, then add 10-12kg of cornstarch and mix well Finally, quantitative packaging is carried out, wherein the tumbling speed is 3r / min. The ingredients of A include: 1.7kg of edible salt, 0.7kg of white sugar, 3.5g of food powder, 2kg of chicken powder, 0.6kg of sodium diacetate, 0.2kg of terry phosphorus crisp, 0.4kg of special phosphorus, 1.4kg of loose meat powder, D- Erythorbic acid 1.5kg. B ingredients include: red pepper 80g, black pepper 1kg, cooking wine 5kg, Beijing shochu 1kg, vegetable juice 72.5kg, water 105kg. Crushed ice is also added to B ingredient in summer. D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com