Multidimensional electromagnetic modulating device for electromagnetic stirring of slab crystallizer

An electromagnetic stirring and crystallizer technology, which is applied in the field of electromagnetic stirring devices, can solve the problems of being unable to adjust, not considering the longitudinal difference of the slab, and the electromagnetic stirring of the slab has not yet been realized, and achieves the effect of wide application range and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

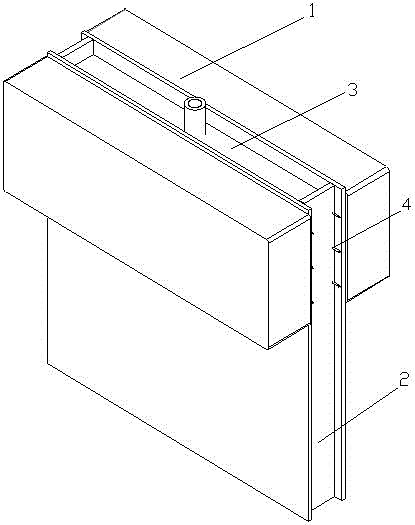

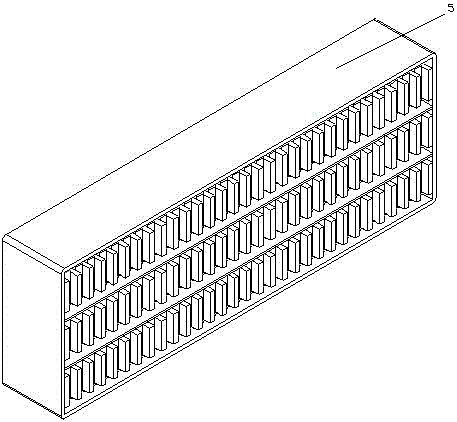

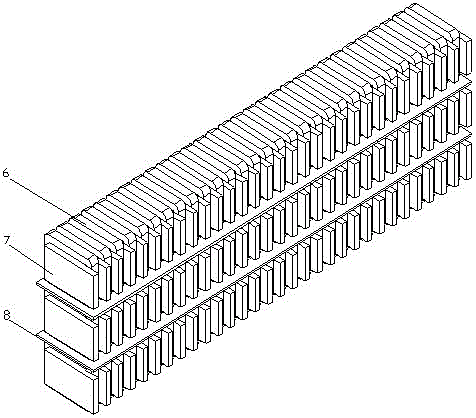

[0036] A multi-dimensional magnetic field modulation device for electromagnetic stirring of a slab crystallizer, comprising a mold system 2, a molten metal 3, an agitator system 1 and a velocity measurement system 4, see figure 1 , the crystallizer system 2 includes a wide mold surface 10, a narrow surface 9 and a submerged nozzle 11, the wide mold surface 10 and the narrow surface 9 are made of copper plates, the wide mold surface 10 on both sides and the narrow mold surface 9 on both sides Constitutes the crystallizer cavity, see Figure 4 , Molten metal 3 is housed in the crystallizer system 2 .

[0037] The agitator system 1 includes a PLC control unit and two unilateral agitators, and the two unilateral agitators are respectively distributed on the wide surfaces 10 on both sides of the crystallizer system 2, and the unilateral agitator in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com